A hydrogen isotope exchange membrane reaction module

A hydrogen isotope, exchange membrane technology, applied in the direction of hydrogen isotope, hydrogen, non-metallic elements, etc., can solve the problems of accelerated Q permeation, Pd-based alloy tube growth, no related reports, etc., to achieve high conversion rate and decontamination factor, The effect of improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

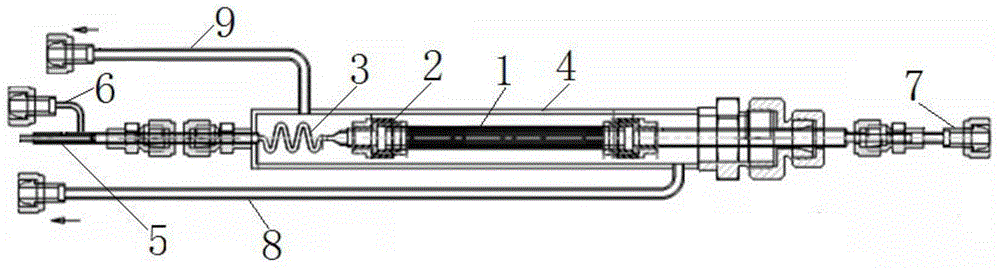

[0023] A hydrogen isotope exchange membrane reaction module, such as figure 1 As shown, it includes: palladium composite membrane tube 1, flange 2, corrugated stainless steel tube 3, outer sleeve 4, thermocouple sleeve 5, hydrogen isotope exchange feed gas inlet 6, permeate gas outlet 7, carrier gas He and Q 2 O feed gas inlet 8, tail gas outlet 9, etc., wherein:

[0024] The base material of the palladium composite membrane tube 1 is porous ceramics or porous stainless steel, the length of the membrane tube: 5-120cm, the outer diameter of the membrane tube: 3-25mm, the thickness of the membrane tube: 1-4mm, and is deposited on the surface of the base material by chemical vapor deposition A layer of palladium film, the total length of the deposited palladium film: 5-30cm, and the thickness of the palladium film: 2-10μm.

[0025] One end of the palladium composite membrane tube 1 is connected to the corrugated stainless steel tube 3 through the flange 2, and the flanges 2 at b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com