Underground diaphragm wall grooving quality detecting device with electronic compass and underground diaphragm wall grooving quality detecting method

An underground diaphragm wall and detection device technology, which is applied in the field of foundation soil survey, foundation structure test, construction, etc., can solve the problems of difficult determination of accurate values, weak acoustic reflection signals, and bulky detection equipment, etc., and achieve accurate detection results and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0098] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

[0099] 1. Device

[0100] 1. Overall

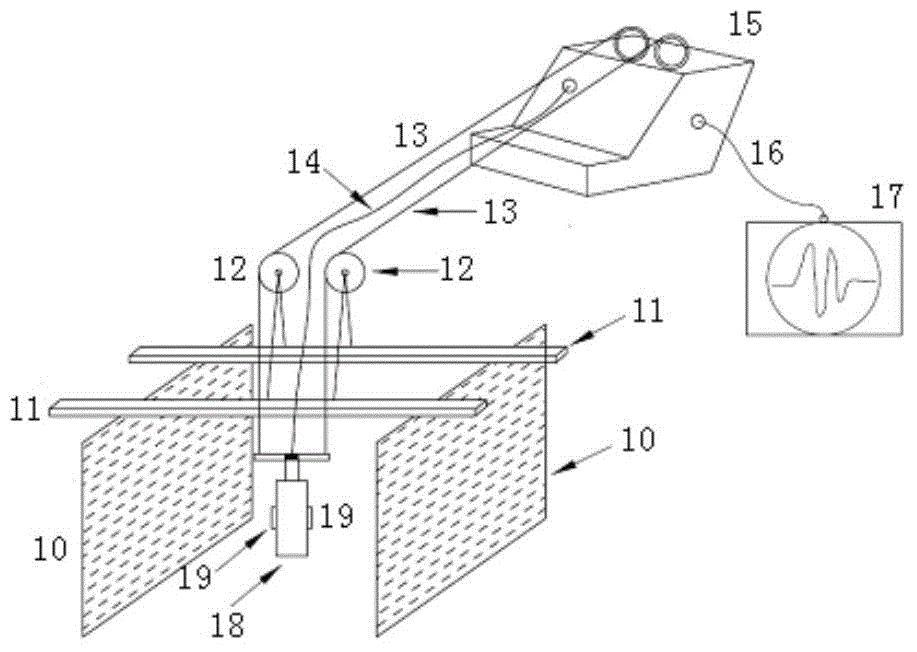

[0101] Such as Figure 4 , the device comprises an underground diaphragm wall 10 (object to be measured), a support 11, a pulley 12, a signal cable 14, and a host connection 16;

[0102] A new electric winch 20 and a new host 21 are replaced, and a new downhole probe 100 is installed;

[0103] Its location and connection relationship are:

[0104] A support 11 is provided at the notch of the underground continuous wall 10, and a pulley 12 is provided on the support 11;

[0105] The low end of the signal cable 14 is connected with the novel downhole probe 100, and the high end of the signal cable 14 is connected with the novel electric winch 20 through the pulley 12;

[0106] Novel electric winch 20 is connected on the novel main engine 21 by main engine connecting line 16.

[0107] 2. Functional components

[0108] 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com