Spiral fire grate self-deslagging burner

An automatic slag removal and burner technology, which is applied in the direction of combustion methods, combustion equipment, and solid fuel combustion, can solve problems such as complexity, laborious slag removal, and large structure, so as to reduce failures and costs, solve slagging, and improve The effect of combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

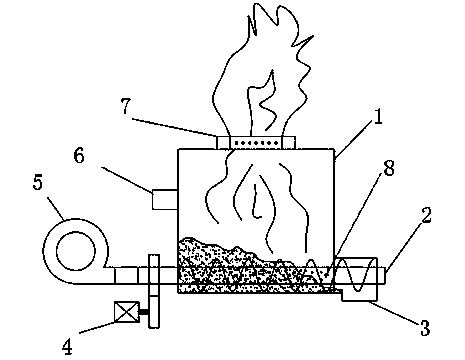

[0009] See figure 1 , The names of the parts are as follows: furnace body 1, auger shaft 2, ash outlet 3, motor 4, fan 5, feed inlet 6, secondary air outlet 7, and air outlet 8.

[0010] See figure 1 , The spiral grate automatic slag removing burner includes a furnace body 1, and the furnace body 1 has an ash outlet 3, a feed inlet 6, and a secondary air outlet 7. Auger shaft 2 penetrates through the lower part of the furnace body 1. The auger shaft 2 is a hollow shaft with multiple air outlet holes 8; one end of the auger shaft 2 is connected to the motor 4 and the fan 5, and the other end is connected to the ash outlet 3 . The upper end of the furnace body 1 is a fire outlet, which is connected to other heat exchangers.

[0011] Biomass particles enter the furnace body 1 from the inlet 6 and continuously move from left to right as the auger shaft 2 rotates; the fan 5 passes through the hollow auger shaft 2 full of air outlets 8 (or wind eye) The primary air is continuously in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com