Rotary kiln with flexible support structure

A flexible support and rotary kiln technology, applied in the field of rotary kiln, can solve problems such as center of gravity axis coincidence, and achieve the effect of prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

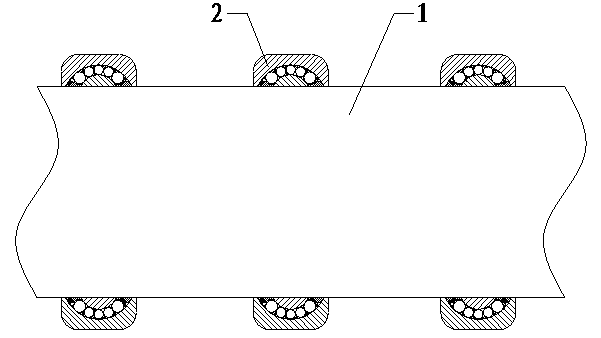

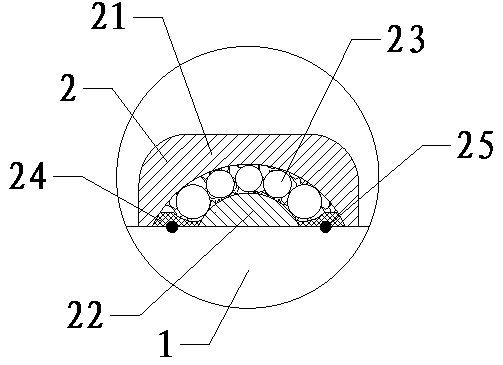

[0012] The present invention will now be described in further detail with reference to the accompanying drawings. These drawings are all simplified schematic diagrams, and only illustrate the basic structure of the present invention in a schematic manner, so they only show the structures related to the present invention.

[0013] like figure 1 and figure 2 The preferred embodiment of the rotary kiln with flexible support structure of the present invention as shown includes a rotary kiln body 1, a flexible support device 2 is provided on the side wall of the rotary kiln body 1, and the flexible support device 2 has a sleeve. The annular casing 21 on the side wall of the rotary kiln body 1 has an annular groove on the inner annular wall of the annular casing 21, and a support ring with a semicircular arc in cross-section is arranged in the annular groove. 22. The inner side of the support ring 22 is welded and fixed on the side wall of the rotary kiln body 1. A plurality of r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com