Noncontact optical volume measurement method for complex-surface and irregular objects

A complex surface and optical measurement technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of inconvenient measurement process, expensive instruments, unsuitable for promotion, etc., to achieve convenient operation, high precision, and suitable for large-scale promotion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

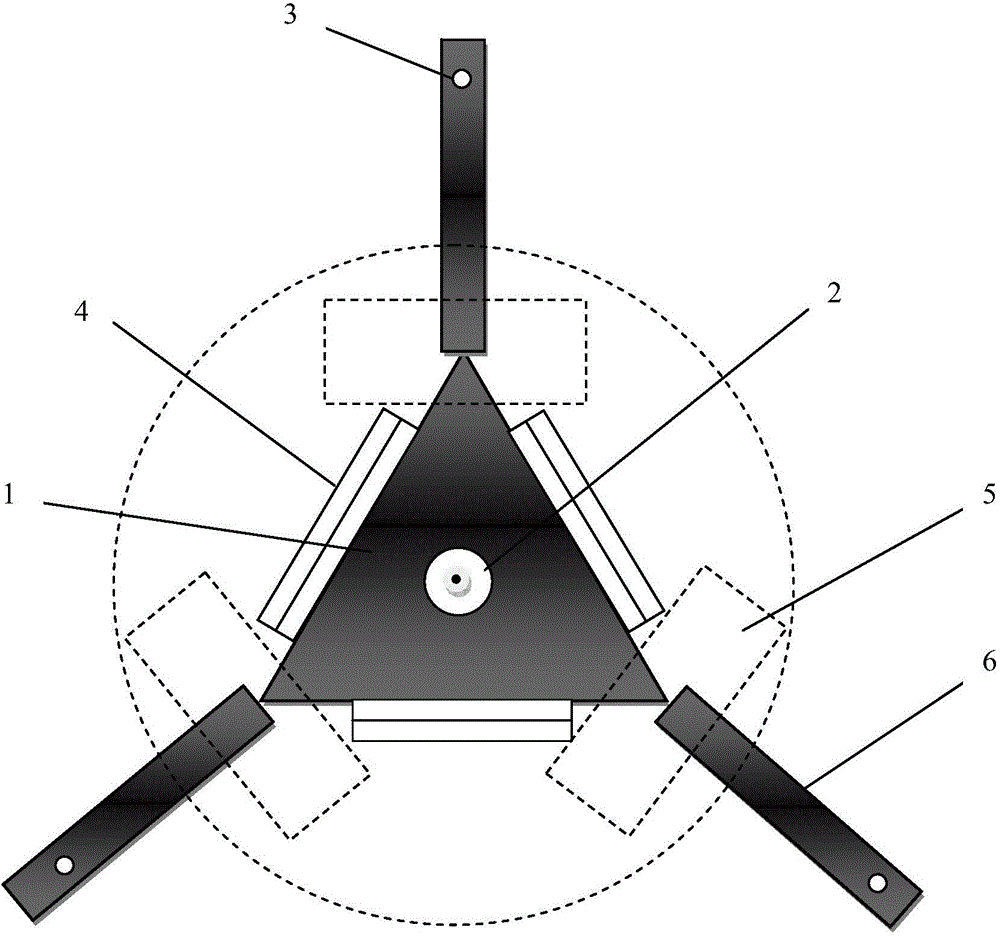

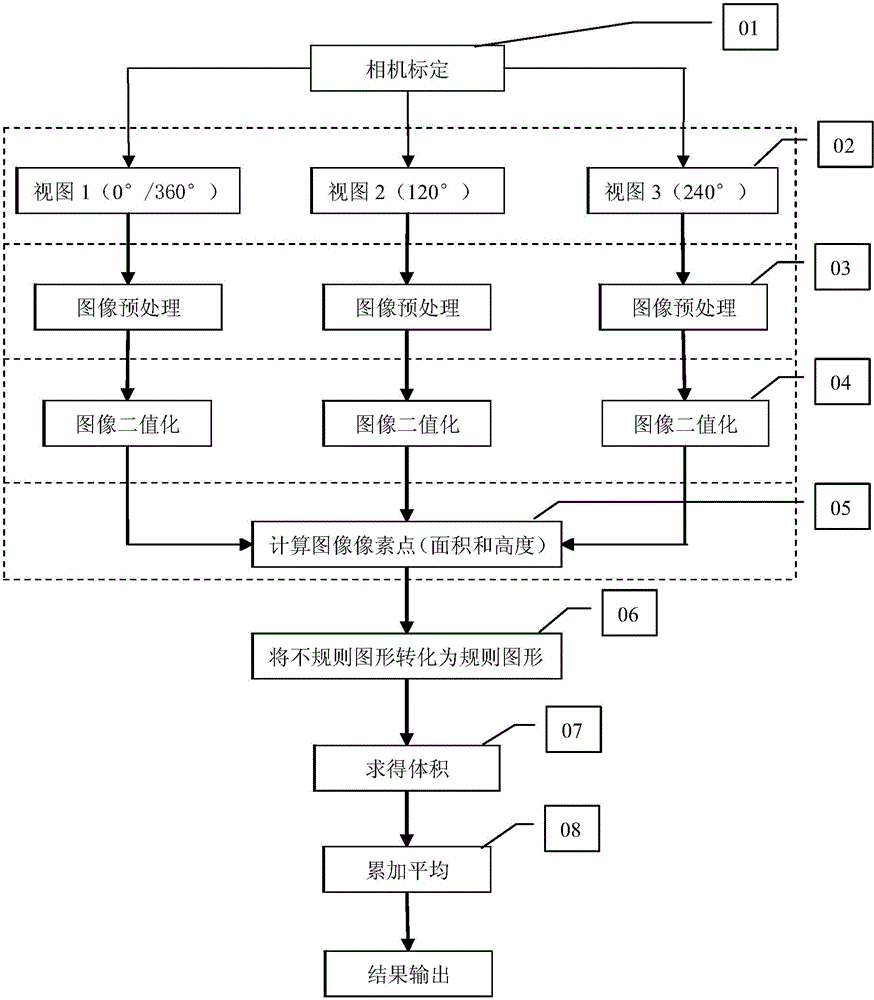

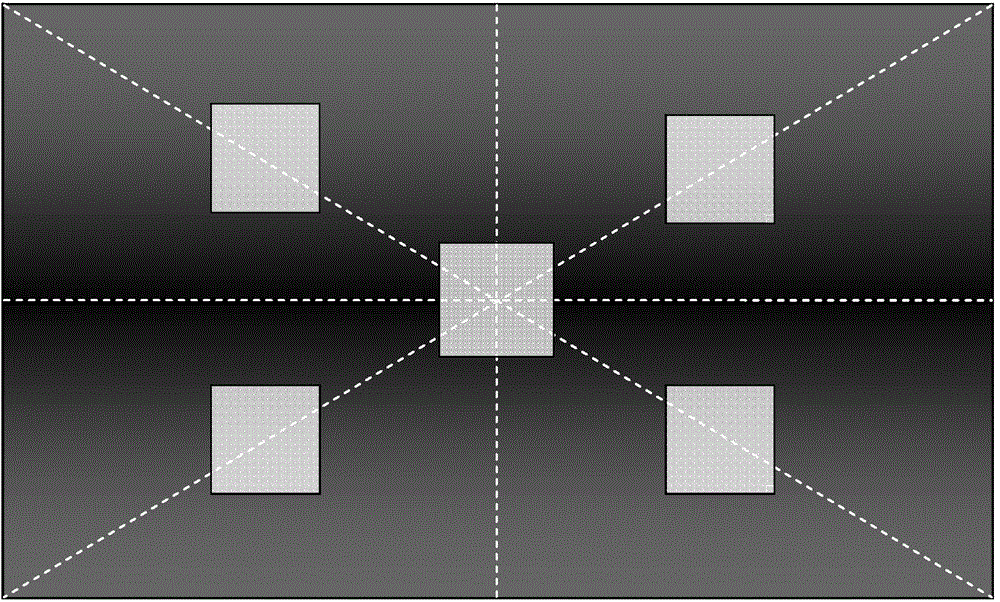

[0046] Such as Figures 1 to 12 As shown, the embodiment of the present invention provides an object volume measurement device for measuring complex surfaces to realize object volume measurement on complex surfaces, such as some protrusions or depressions on the surface. The specific principles are as follows:

[0047] In this embodiment, three SunTime FX30 color 1 / 4"CCD image sensors are used to collect images. The working voltage is 5V, the working current is 400mA, the effective pixel is 680H*480V, and the scanning method is progressive scanning. USB2.0 CMOS / CCD high-speed series products, using SONY high-end CCD photosensitive chip, has the characteristics of good color reproduction, high image quality, and high sensitivity. It provides high-precision raw data for object volume measurement.

[0048] Since we use the LabVIEW program to control the rotation platform 2 to let the camera 3 take an image every time it rotates 0.9 degrees, since 120 degrees is not an integer mu...

Embodiment 2

[0067] An embodiment of the present invention provides a volume measurement device for irregularly shaped objects to realize the volume measurement of irregularly shaped objects. The specific principles are as follows:

[0068] Before the measurement, we adjust the measuring device, adjust the three mechanical arms 5, make the angle between the three mechanical arms 5 be 120 degrees and align each camera 3 with the center of the rotating platform 2, adjust the level of the rotating platform 2, And make the camera 3 parallel to the rotating platform 2, turn on the auxiliary light source 6, so that the light of the auxiliary light source 6 evenly shines on the object under test. And complex surface objects are placed in the middle of the rotating platform 2 to facilitate volume measurement.

[0069] The stepping motor is controlled by the LabVIEW program to drive the rotating platform 2 to rotate, and three cameras 3 are simultaneously controlled to take pictures of the measured...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com