Continuous wood dynamic elastic modulus eccentric pressure roller testing equipment and method

A technology of dynamic elastic modulus and detection equipment, applied in the field of grade detection, can solve problems such as wood expansion error value, and achieve the effect of eliminating detection errors and avoiding influences.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

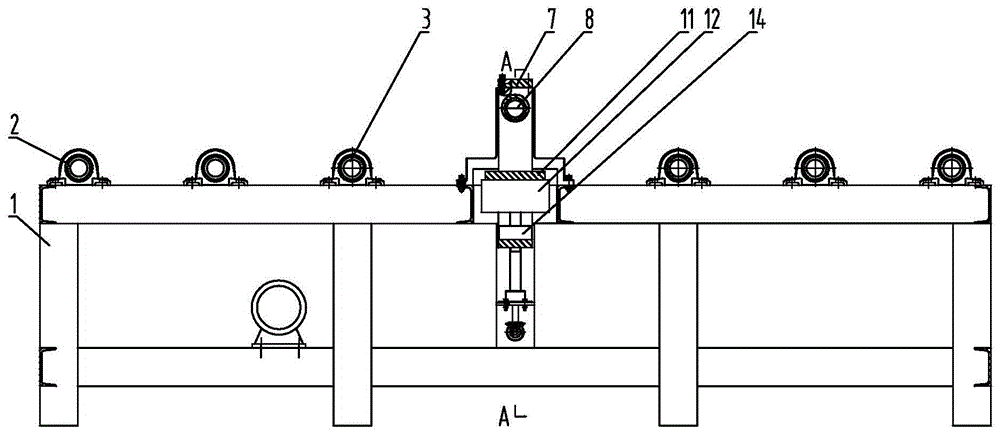

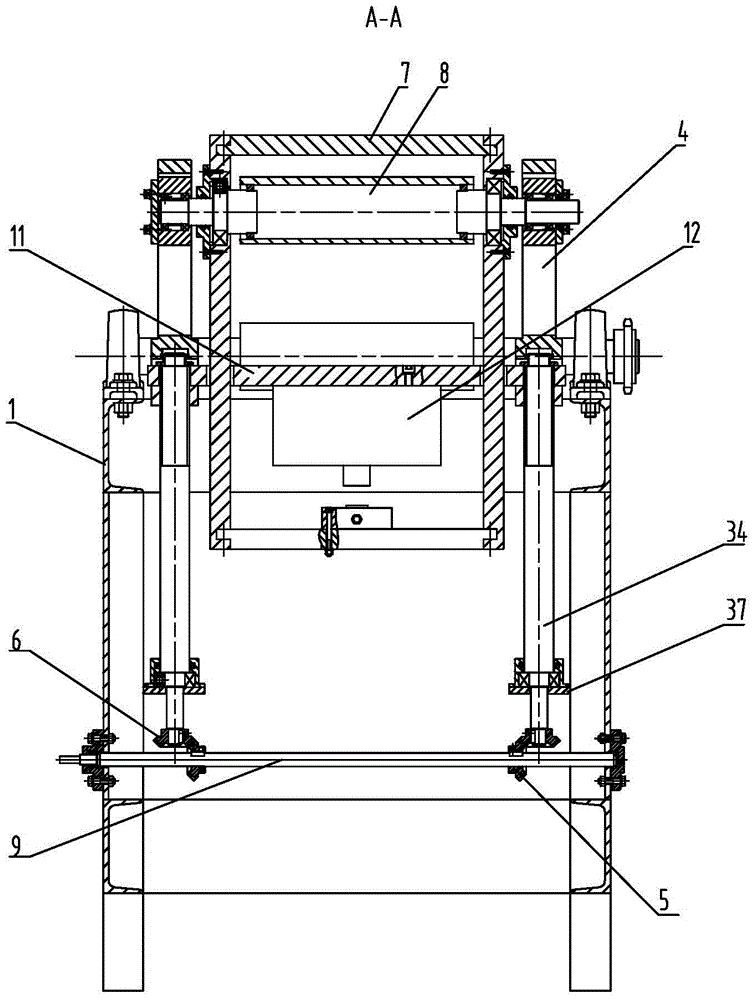

[0044] Specific implementation mode one: combine figure 1 and figure 2 To illustrate, the continuous wood dynamic modulus of elasticity eccentric pressure roller testing equipment in this embodiment includes:

[0045] Frame 1, at least four auxiliary backup rolls 2, at least two main backup rolls 3, head frame 7, eccentric roll head 8, pneumatic cylinder 12 and sensor 14;

[0046] Described frame 1 is provided with at least six groups of backup rollers along its lengthwise direction, including at least four groups of auxiliary backup rollers 2 and two groups of main backup rollers 3, two groups of main backup rollers 3 are positioned at the middle part of frame 1, two The set of main support rolls 3 is arranged symmetrically with the center line of the frame 1, at least four groups of auxiliary support rolls 2 are arranged on both sides of the main support roll 3, the press head frame 7 is arranged on the frame 1, and the press head frame 7 The centerline of the centerline ...

specific Embodiment approach 2

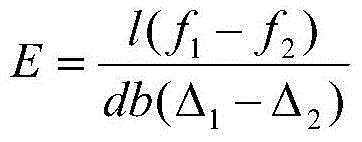

[0048] Specific embodiment two: this embodiment is based on the realization of specific embodiment one, the continuous wood dynamic elastic modulus eccentric pressure roller detection method, the specific steps are: the wood test piece is transported to the bottom of the eccentric roller pressure head 8 by the support roller, And the eccentric roller head 8 corresponds to the midpoint of the effective length of the timber specimen, and the pneumatic cylinder applies a load to the midpoint of the effective length of the timber specimen, and the load change value of the timber specimen is detected by the load cell, which is brought into the elastic modulus calculation formula to obtain the modulus of elasticity value;

[0049] E = l dbP ( f 1 - f 2 )

[0050] In the formula:

[0051] l:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com