Insulation withstand voltage test tooling

A technology of withstand voltage test and insulating parts, applied in the direction of testing dielectric strength, etc., can solve the problems of poor generality of the withstand voltage test device, reduce the test efficiency, increase the test cost, etc., to reduce the test cost, improve the test efficiency, The effect of improving the economic efficiency of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

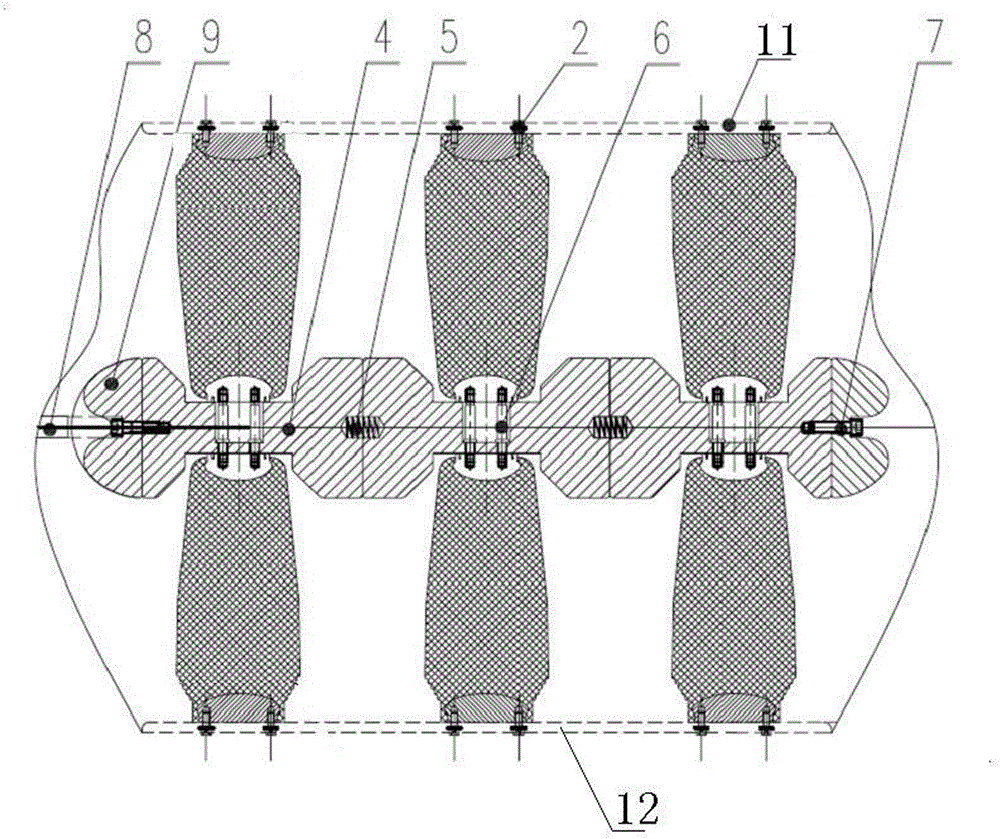

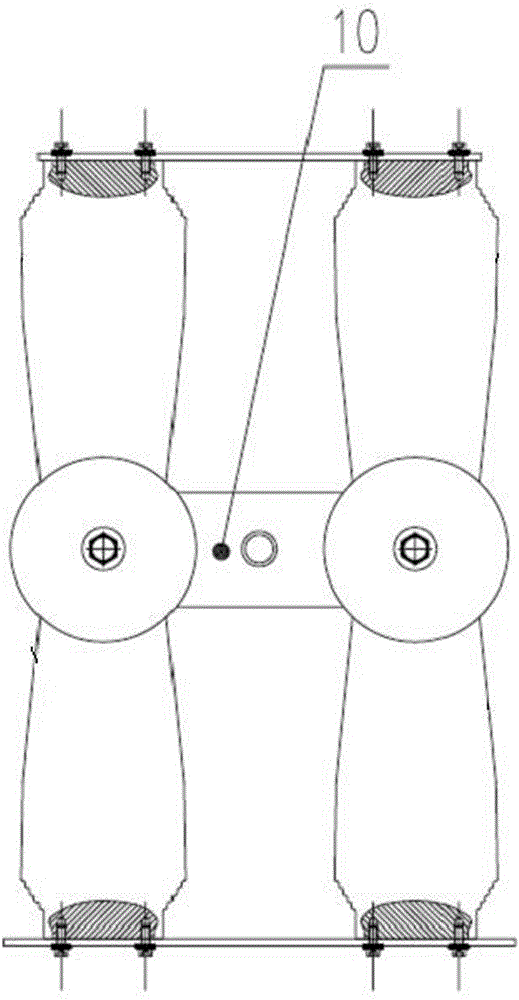

[0017] The embodiment of the insulation withstand voltage test tooling of the present invention: as Figure 1 ~ Figure 2 As shown, the insulator withstand voltage test tooling includes a first electrode plate 11 and a second electrode plate 12 arranged in parallel up and down, the first electrode plate and the second electrode plate are both flat electrodes, and the two electrode plates are provided with Two sets of connection structures for connecting and fixing the insulator to be tested, the connection structure is the fastening bolts 2 arranged at intervals on the two electrode plates and the fastening bolts 2 fixed on the two electrode plates for connecting with the insulator to be tested Interference fit is used to fix the spacer of the insulator to be tested, and also includes a central conductive rod for electrically connecting the insulator to be tested, which is arranged between the first electrode plate 11 and the second electrode plate 12, and the central conductive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com