Active-combined passive containment vessel cooling system

A containment cooling, passive technology, applied in cooling devices, nuclear power generation, climate sustainability, etc., to achieve the effect of flexible access, maintaining efficiency, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

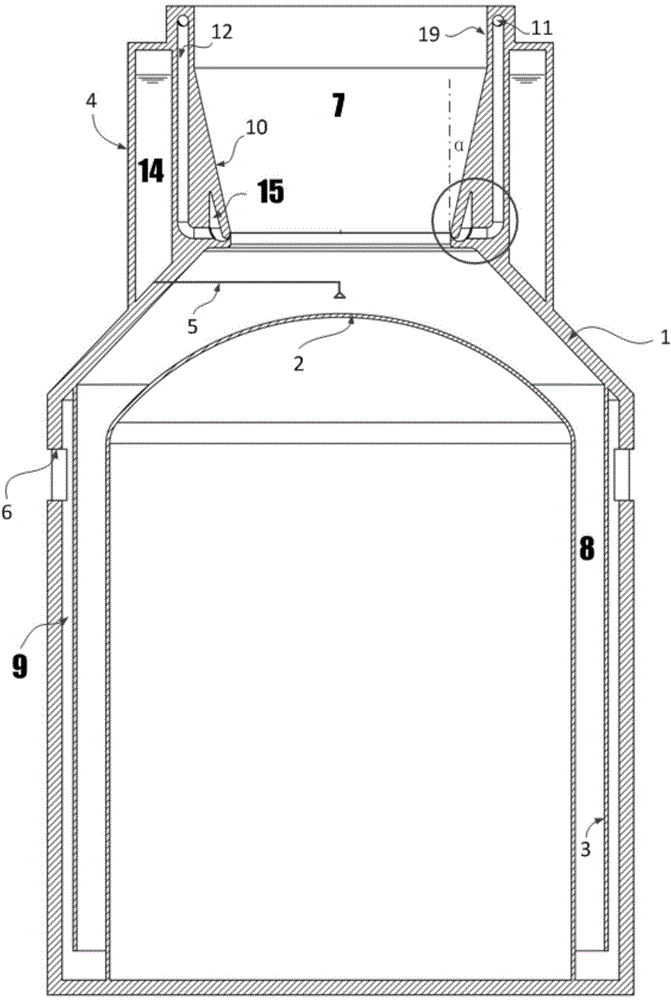

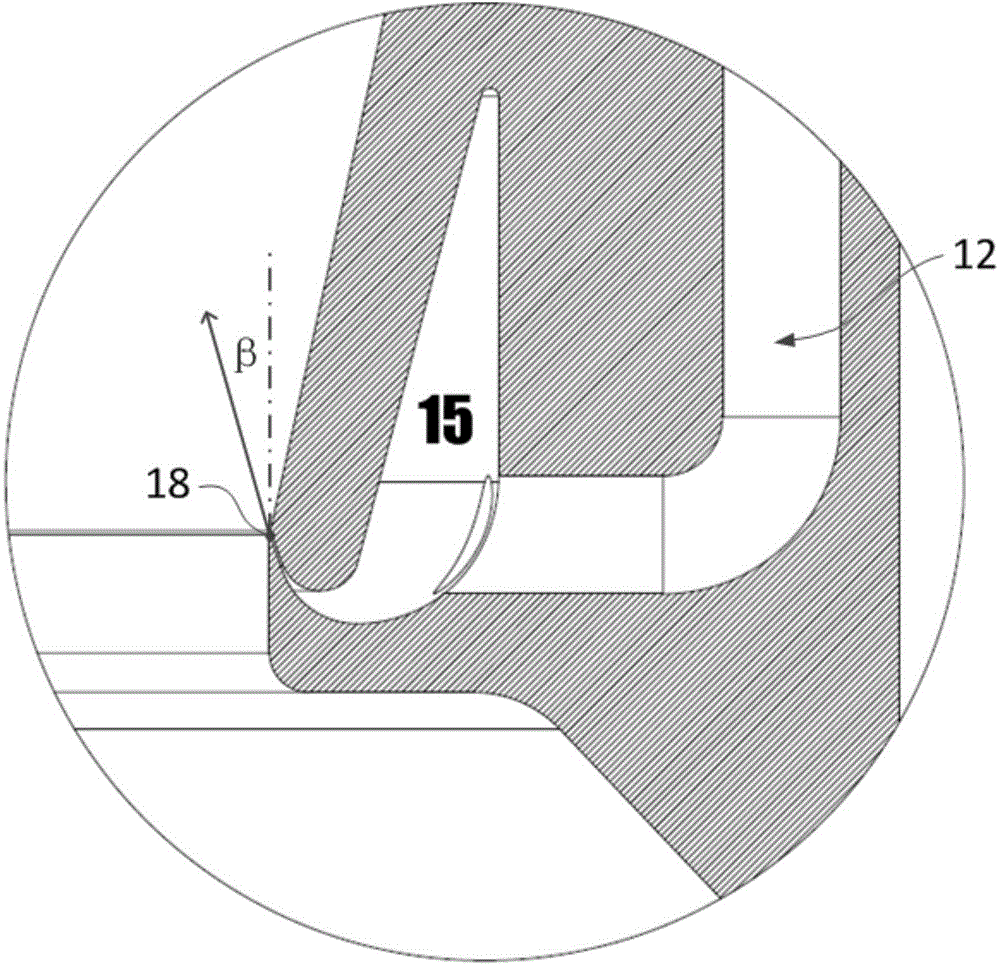

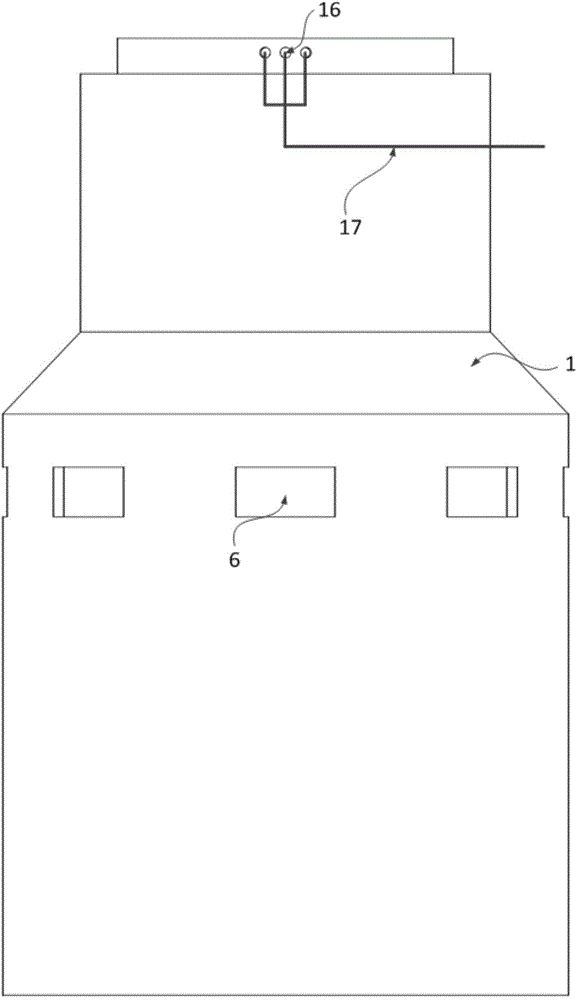

[0020] Such as figure 1 As shown, an active and passive containment cooling system provided by the present invention has a shielding workshop 1, a steel containment vessel 2, an air baffle 3, a top water tank 4, a containment spray pipe 5, and a shielding workshop building. Air port 6. The steel containment vessel 2 is set in the shielded plant 1, and the air baffle 3 is arranged inside the air inlet 6 of the shielded plant, and the air baffle is arranged along the vertical direction to divide the flow space of the air flow into an ascending channel 8 and a descending channel 9 . The top water tank 4 is arranged on the upper part of the shielding plant 1, and the top water tank is arranged in a ring shape and contains a water body 14. The containment spray pipe 5 arranged above the steel containment vessel 2 is connected to the top water tank 4. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com