Dust collecting system of polishing dust removal working table

A technology of dust collection and workbench, applied in the direction of manufacturing tools, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of polluted environment, dust worker harm, and worker harm, etc., to achieve a clean working environment and reduce harm , to avoid the effect of polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

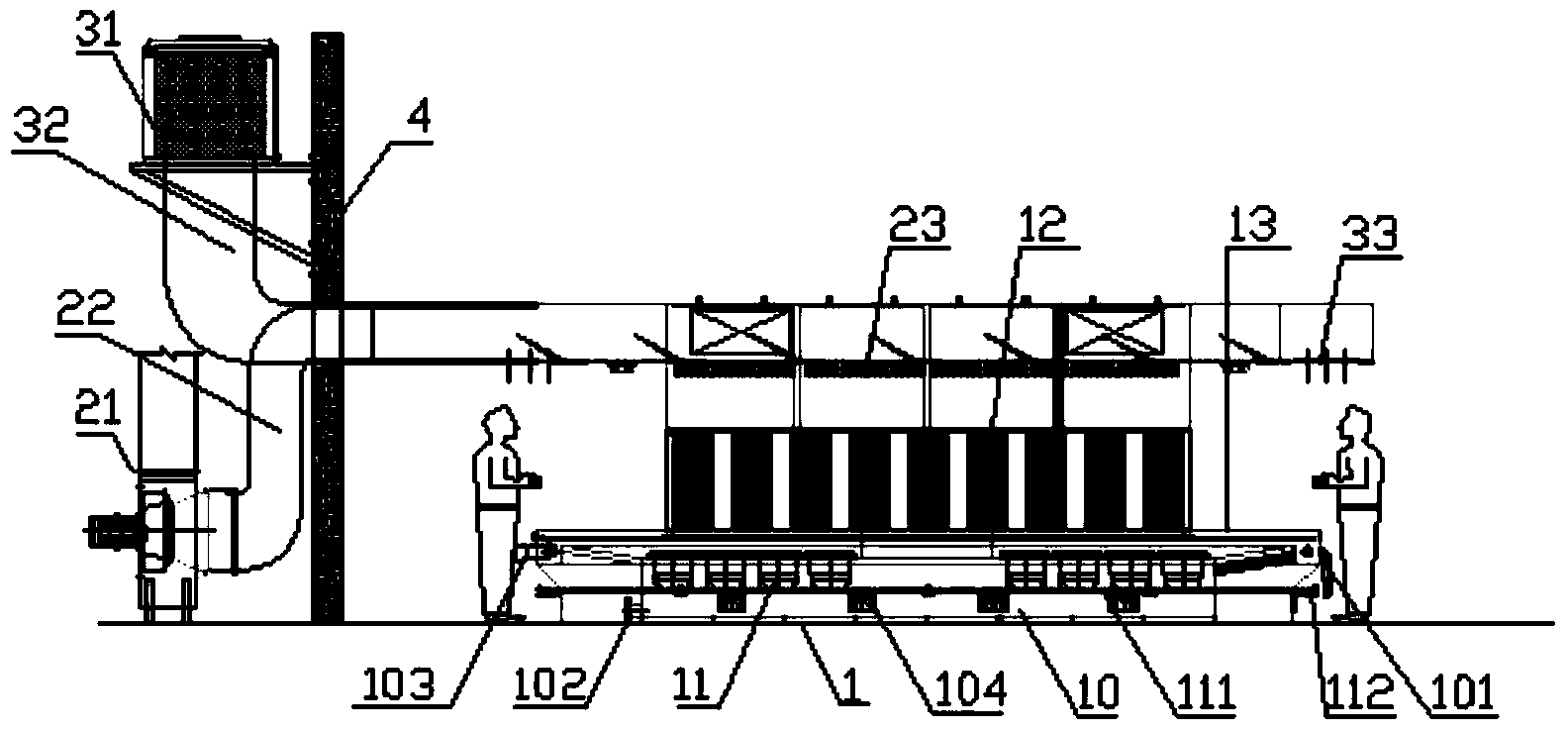

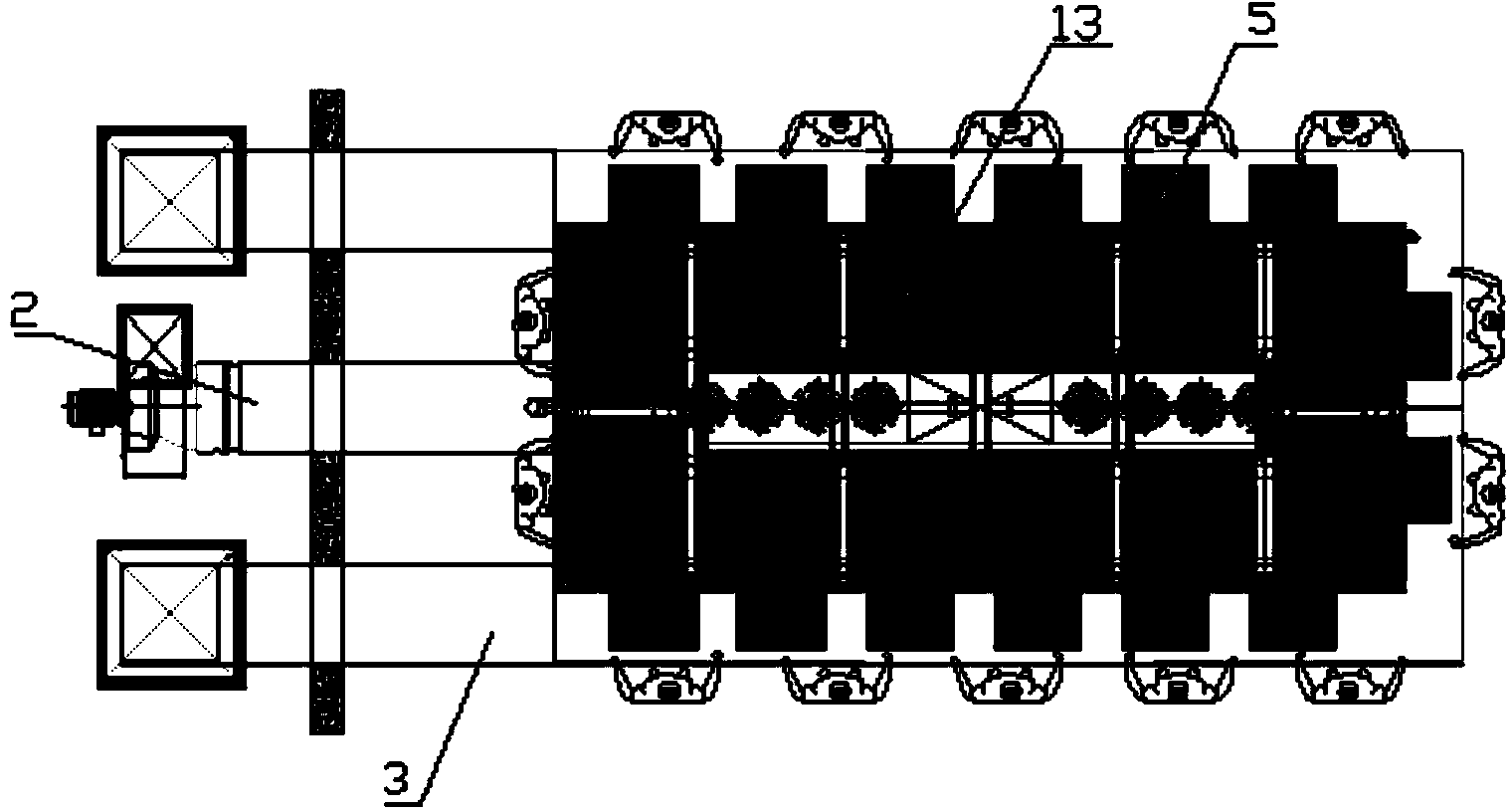

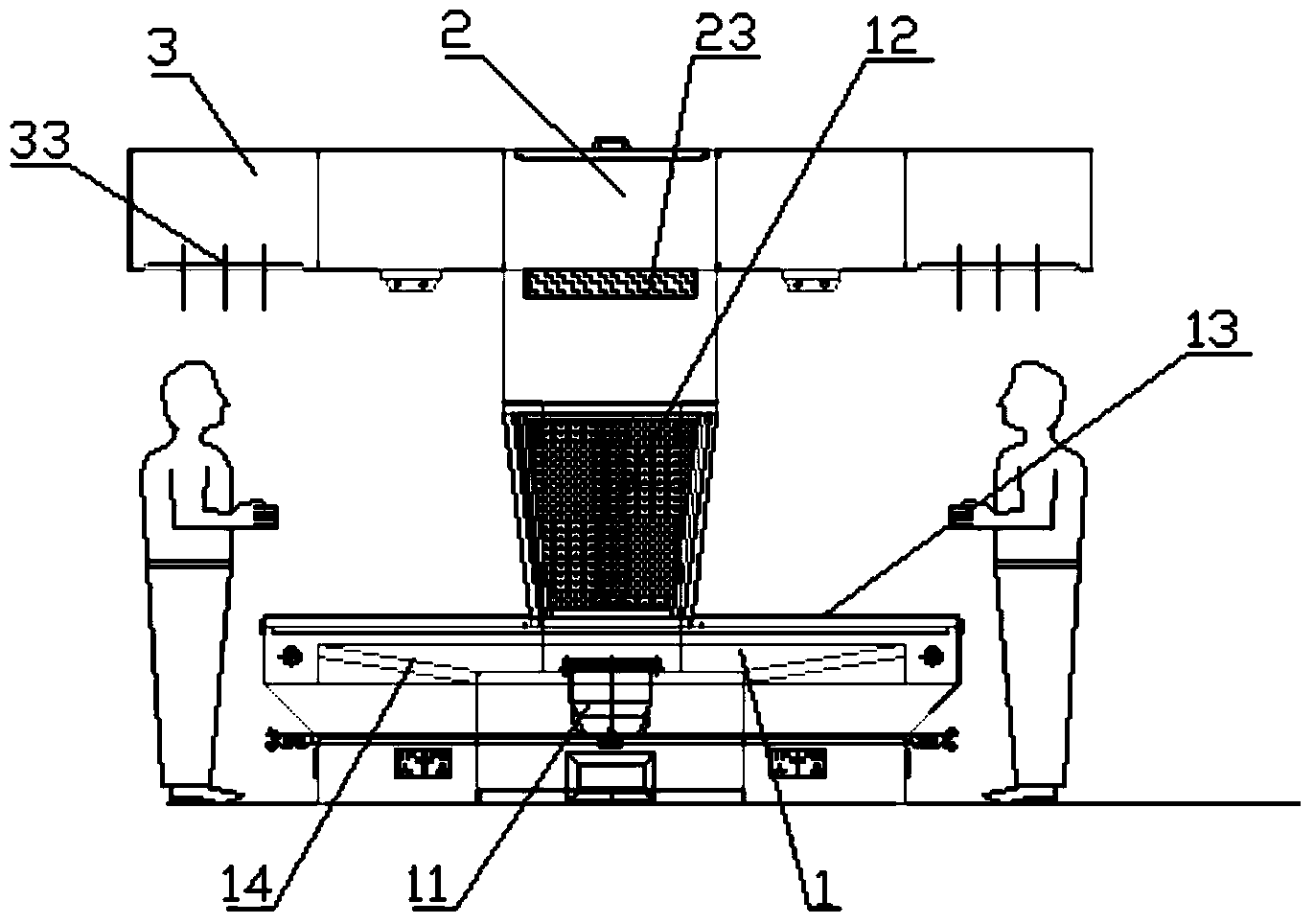

[0013] Such as Figure 1 to Figure 3 As shown, a polishing and dust removal workbench includes a main frame 1, a work surface is provided on the top of the main frame 1, and an air suction chamber surrounded by a vertical operating table side plate 12 is provided above the middle of the work surface , The workbench surface is provided with a horizontal console panel surrounding the suction chamber in the circumferential direction, the workpiece 5 is placed on the console panel for polishing, and the operator stands on the outside of the workbench surface, the console side panel, the console panel and the suction chamber The bottom plate of the air chamber is a perforated plate, the top of the suction chamber is connected to the suction channel 2 for exhausting the air in the suction chamber, the suction channel is provided with water-blocking filter paper, and the upper part of the operation table is connected to the operation table Air supply channel 3 through which the panel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com