A rapid detection device and method for filling content

A technology of testing equipment and fillers, applied in the field of testing, can solve problems such as low accuracy, poor basic performance of modified plastics, complicated operation, etc., and achieve the effects of reducing testing time, ensuring basic performance, and reducing manual operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with drawings and embodiments.

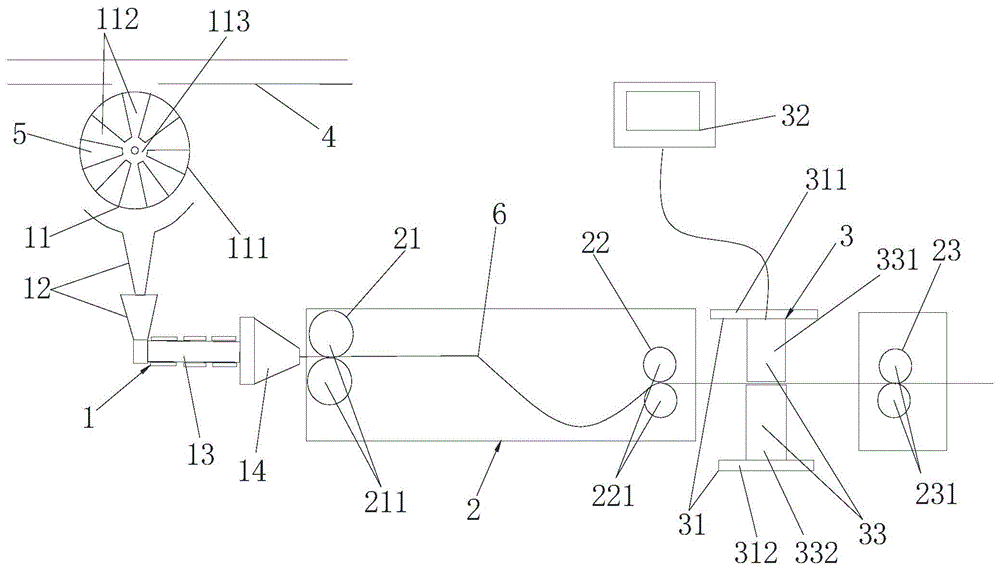

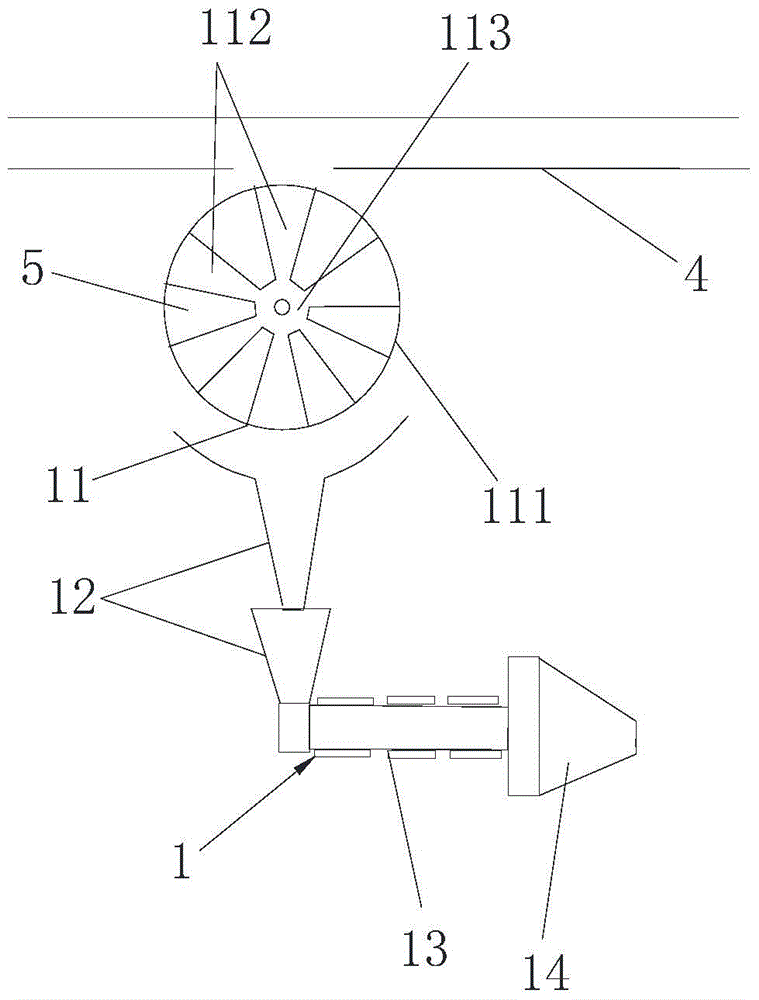

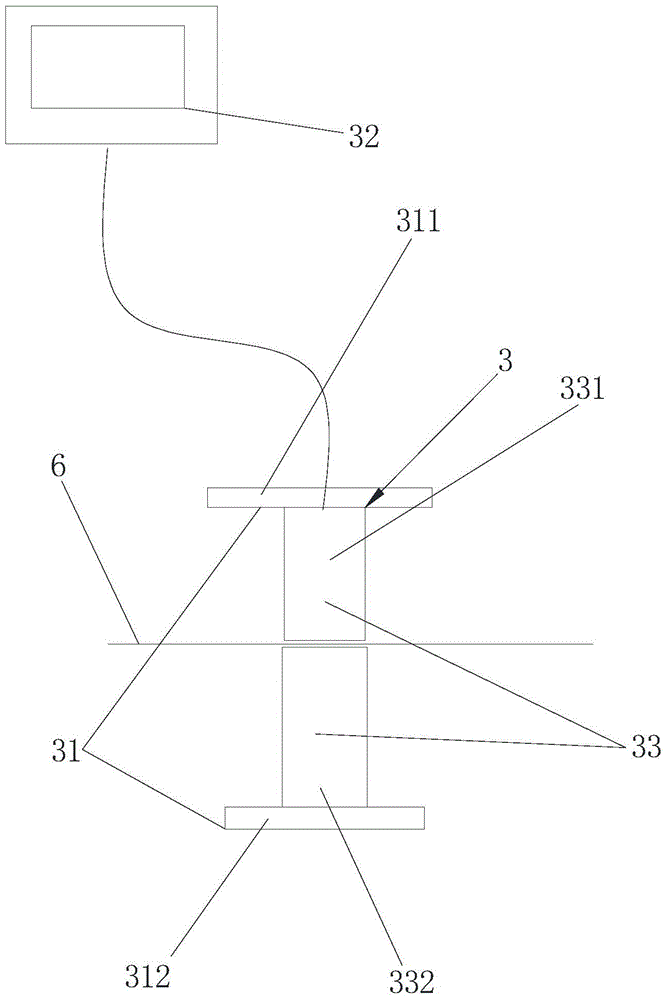

[0025] Such as Figure 1 to Figure 3 The shown rapid detection equipment for filling content includes a casting unit 1, a forming traction device 2 and an infrared spectrum attenuation total reflection test device 3; the casting unit 1 includes a raw material collector 11 connected to a conveying pipeline 4, a lower Hopper 12, extruder 13 and casting machine 14, described lower hopper 12 is installed below collector 11, and the discharge port of described lower hopper 12 is connected with the feed inlet of extruder 13, and described extruder The discharge port of 13 is connected with one end of tape casting machine 14, and the other end of said tape casting machine 14 is connected with one end of forming traction device 2.

[0026] The raw material collector 11 is mainly composed of a cylindrical main body and a motor. The main body includes an outer cylinder 111, a pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com