Hybrid power automobile work mode control method

A hybrid vehicle, working mode technology, applied in hybrid vehicles, motor vehicles, control devices, etc., can solve problems such as the impact of vehicle speed stability, sudden changes in engine output torque and motor output torque, poor adaptability, etc. The effect of driving comfort, reducing mechanical shock, and improving robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

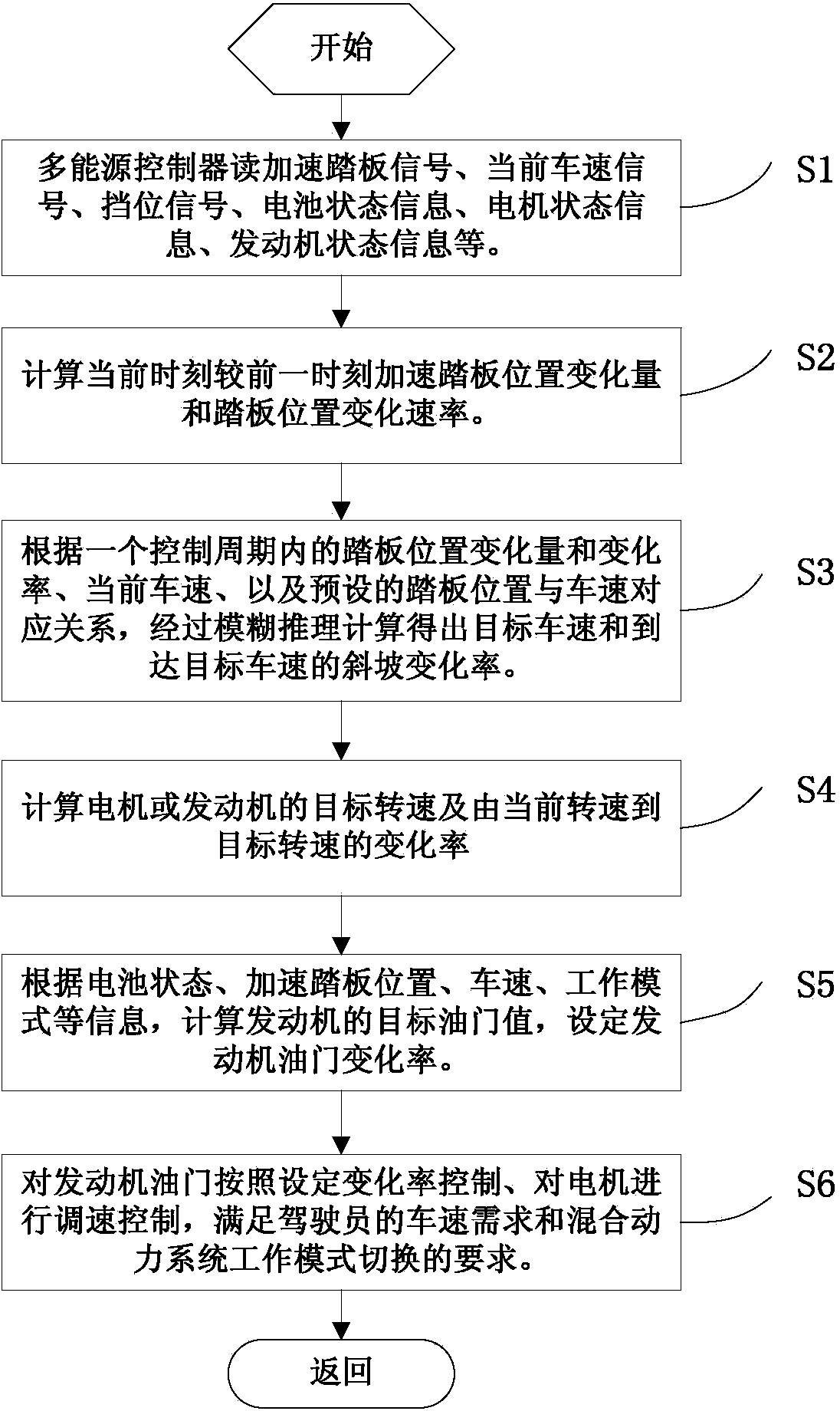

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0018] Step S1. The multi-energy controller of the parallel hybrid electric vehicle reads the accelerator pedal signal, the current vehicle speed signal, the gear signal, the battery status information, the motor status information, the engine status information, the driving mode switch signal, the brake pedal signal, the air conditioner switch and other accessories state.

[0019] Step S2, calculating the accelerator pedal position change amount and the pedal position change rate at the current moment compared with the previous moment.

[0020] Step S3, according to the amount of change in the pedal position and the rate of change of the pedal position within one control cycle, the current vehicle speed, and the preset corresponding relationship between the pedal position and the vehicle speed, the target vehicle speed and the rate o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com