Fluororubber special for automobile fuel hose and preparation method thereof

A technology of fluororubber and fuel oil, which is applied in the field of fluororubber for automobile fuel hoses and its preparation, which can solve the problems of fuel hose aging, reduced service life, hidden safety hazards, etc., and achieves increased service life, good fluidity, and guaranteed use safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

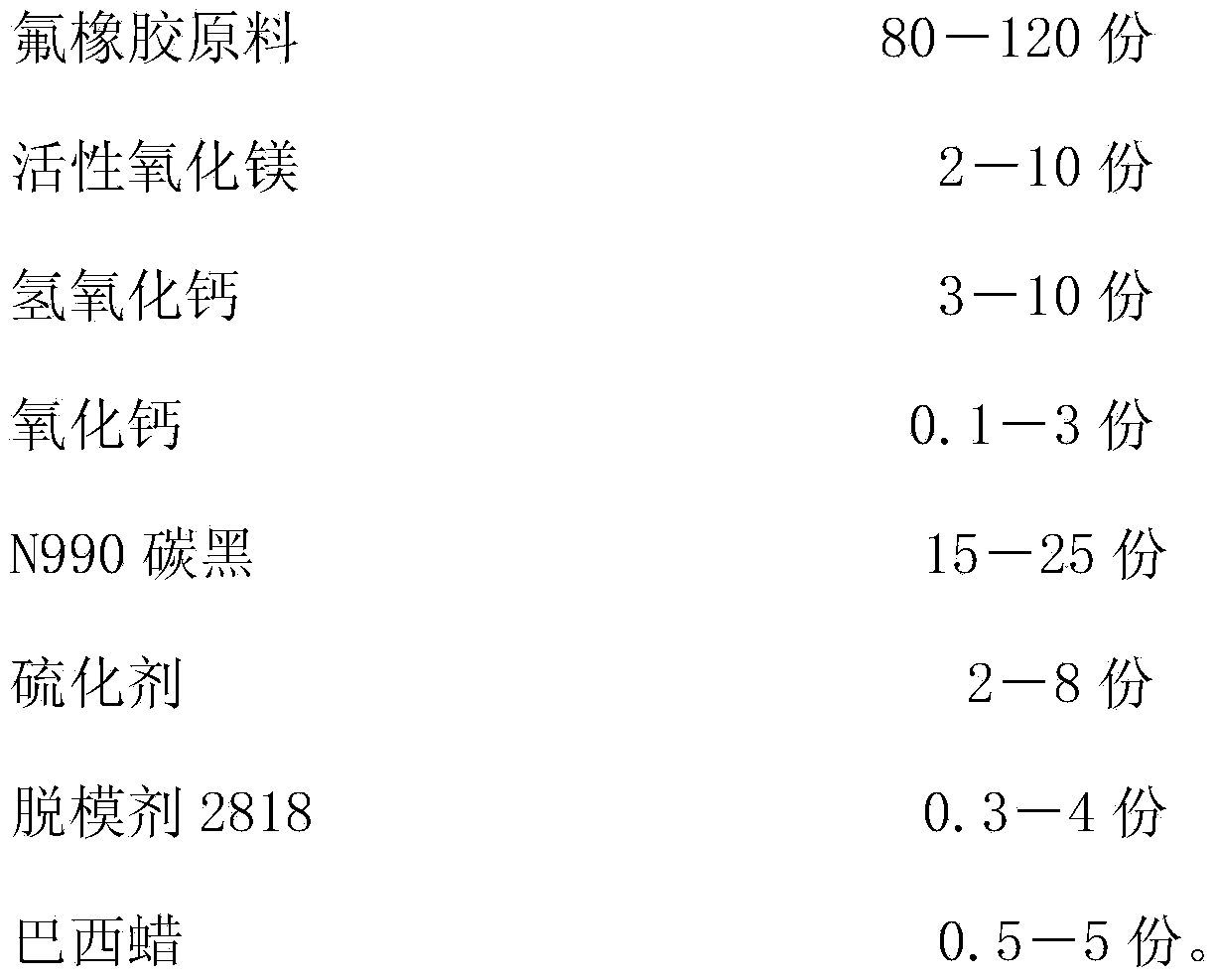

Method used

Image

Examples

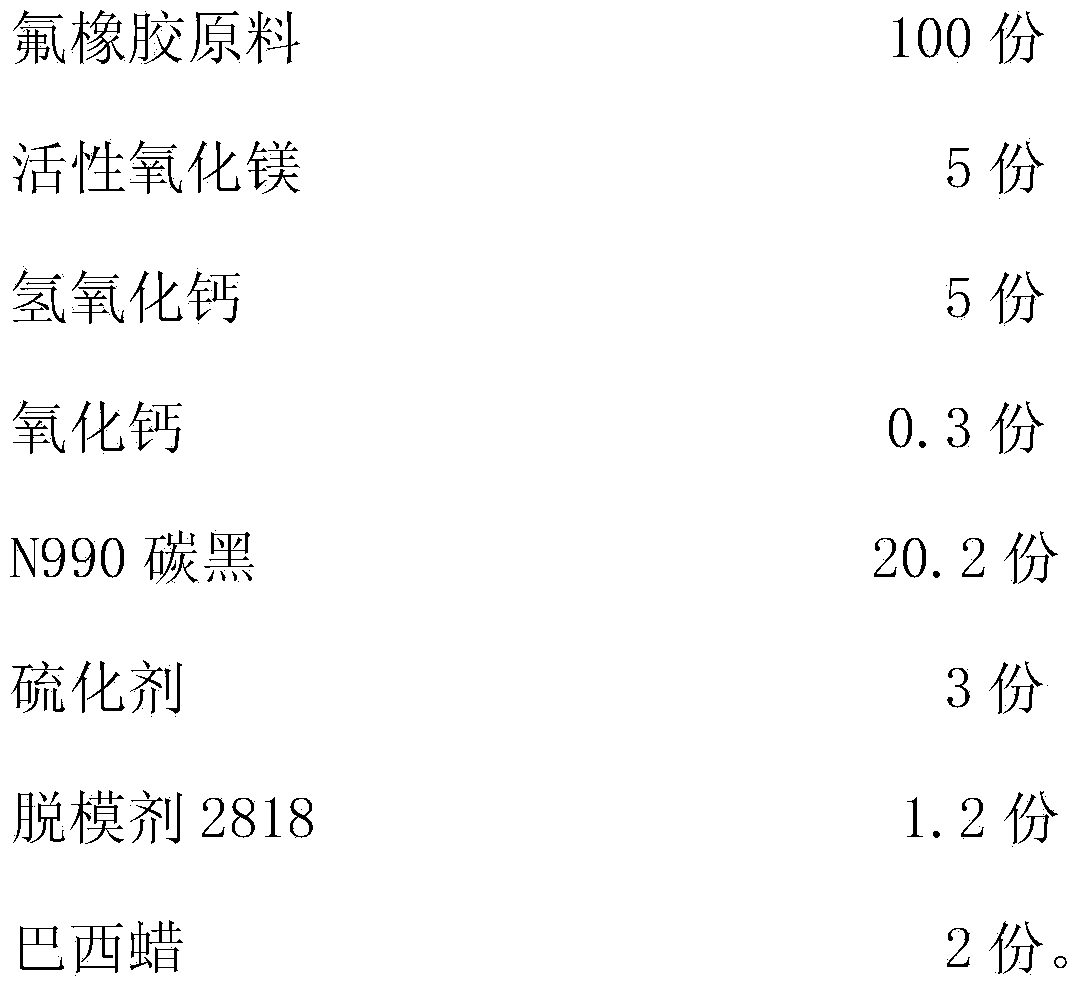

Embodiment 1

[0017] A preparation method of fluororubber specially used for automobile fuel hose, the preparation steps are as follows: 100 parts of fluororubber raw material (1DAL-ELG-343), 5 parts of activated magnesium oxide, 5 parts of calcium hydroxide, 0.3 part of calcium oxide, N990 20.2 parts of carbon black, 3 parts of vulcanizing agent N,N-secondary cinnamyl-1,6-hexanediamine, 28181.2 parts of release agent, 2 parts of Brazilian wax were mixed and formed, the mixing temperature was 155°C, and the pressure was 12KN, the rotational speed of the kneading internal mixer is 50r / min, and the mixing time is 0.8h.

Embodiment 2

[0019] A preparation method of fluororubber specially used for automobile fuel hoses. The preparation steps are as follows: 110 parts of fluororubber raw material (1DAL-ELG-343), 8 parts of activated magnesium oxide, 8 parts of calcium hydroxide, 0.6 part of calcium oxide, and N990 23 parts of carbon black, 4 parts of vulcanizing agent N,N-secondary cinnamyl-1,6-hexanediamine, 28181.5 parts of release agent, 3 parts of Brazilian wax were mixed and formed, the mixing temperature was 160°C, and the pressure was 10KN, the rotational speed of the kneading internal mixer is 55r / min, and the mixing time is 1h.

Embodiment 3

[0021] A preparation method of fluororubber for automobile fuel hose, the preparation steps are as follows: 105 parts of fluororubber raw material (1DAL-ELG-343), 6 parts of activated magnesium oxide, 7 parts of calcium hydroxide, 0.2 part of calcium oxide, N990 19 parts of carbon black, 3.2 parts of vulcanizing agent N, N-secondary cinnamyl-1,6-hexanediamine, 28181.5 parts of mold release agent, 1.3 parts of Brazilian wax were mixed and formed, the mixing temperature was 155 ° C, and the pressure was 12KN, the rotational speed of the kneading internal mixer is 50r / min, and the mixing time is 0.8h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com