A mine pressure control method for fully mechanized top-coal caving face with strong mine pressure appearance

A technology of fully mechanized mining roof caving and control method, applied in mine roof support, mining equipment, earthwork drilling and other directions, can solve the problems of weakened roof, poor roof control effect, large subsidence of working face roof, etc., to ensure safety The effect of production, concise process and clear goals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention discloses a mine pressure control method for fully mechanized top-coal caving working faces where strong mine pressure appears. In order to make the advantages and technical solutions of the present invention clearer and clearer, the present invention will be further clarified and complete in combination with specific examples below illustrate.

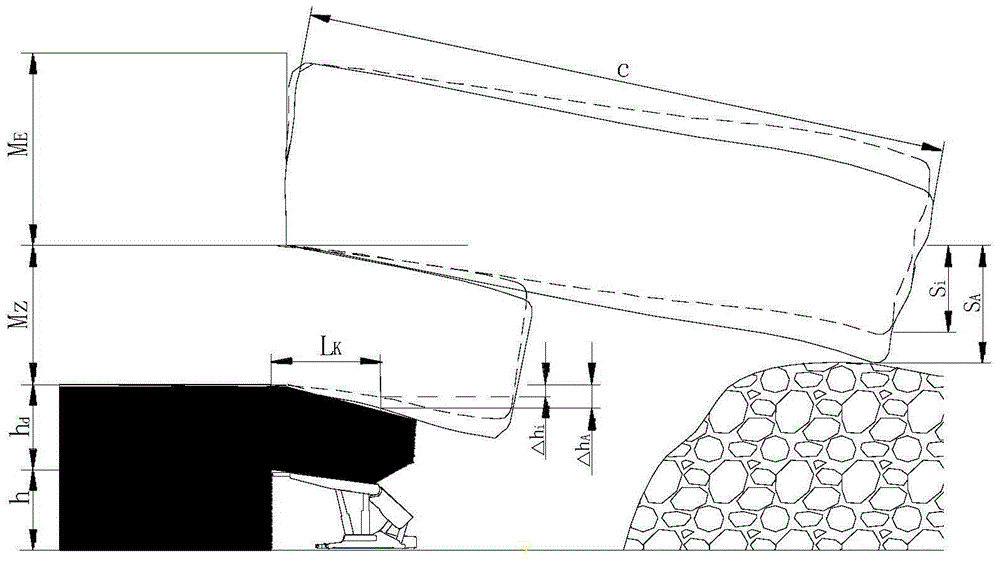

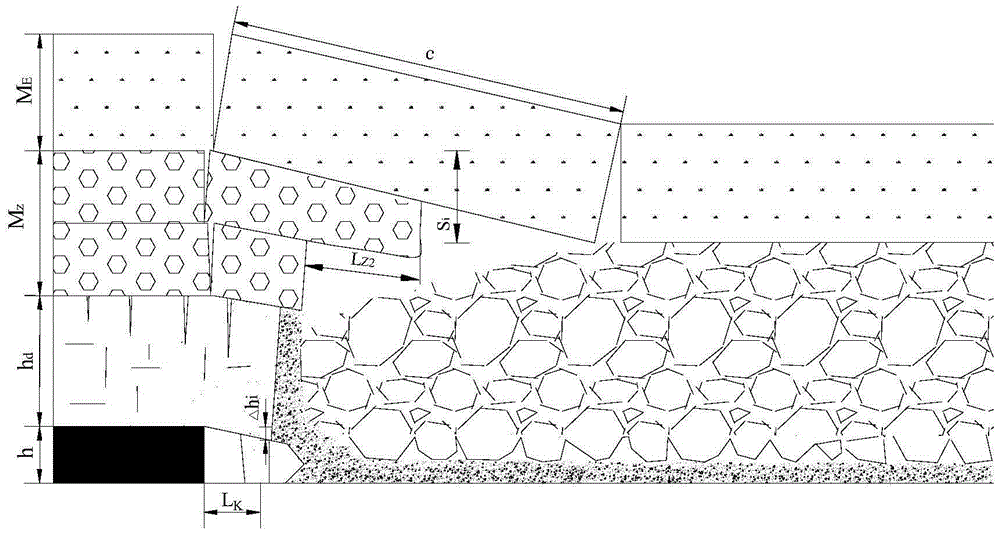

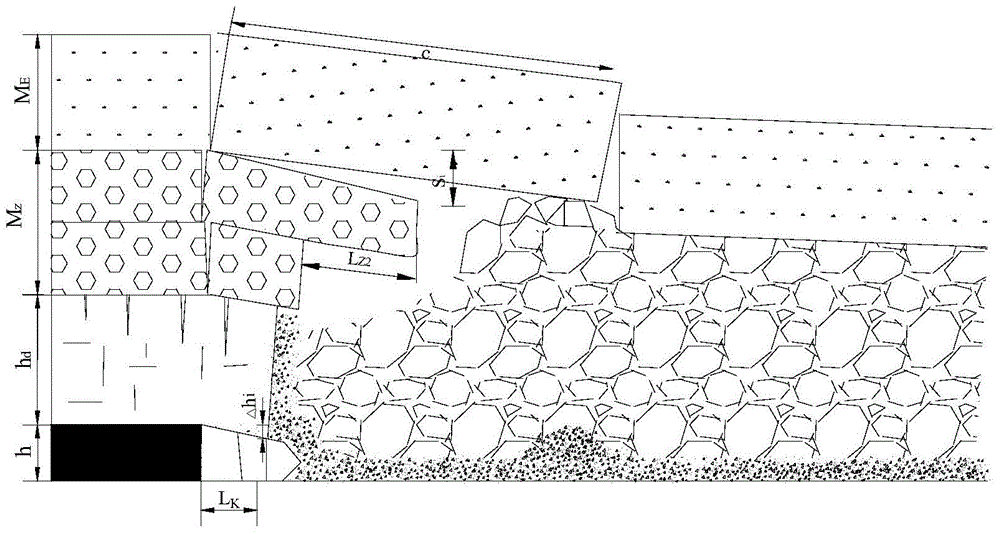

[0044] Take a mine 6 上 105-2 fully mechanized mining top coal caving face as an example, combined with figure 1 , figure 2 , image 3 , Figure 4 As shown, the mine pressure control method of the present invention is described in detail. The present invention, a mine pressure control method for fully mechanized mining top coal caving face with strong mine pressure, specifically comprises the following steps:

[0045] Step 1. Define the degree of strong mine pressure in the fully mechanized top coal caving face, and evaluate it mainly in combination with the following process parameters.

[0046] (1) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com