Fault diagnosis method for flow passage of steam turbine

A technology for through-flow parts and fault diagnosis, which is used in the testing of machine/structural components, measuring devices, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

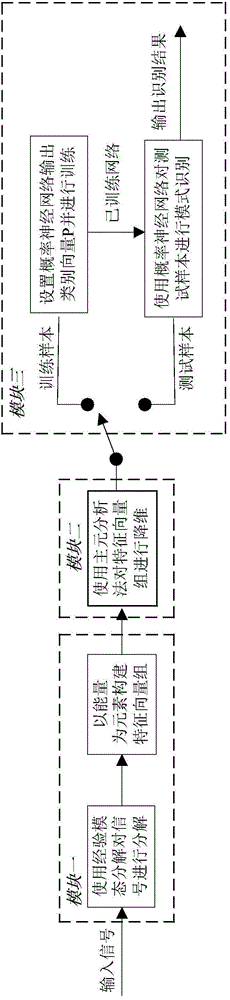

[0046] Such as image 3 As shown, the diagnostic method proposed by the present invention is mainly divided into three major modules.

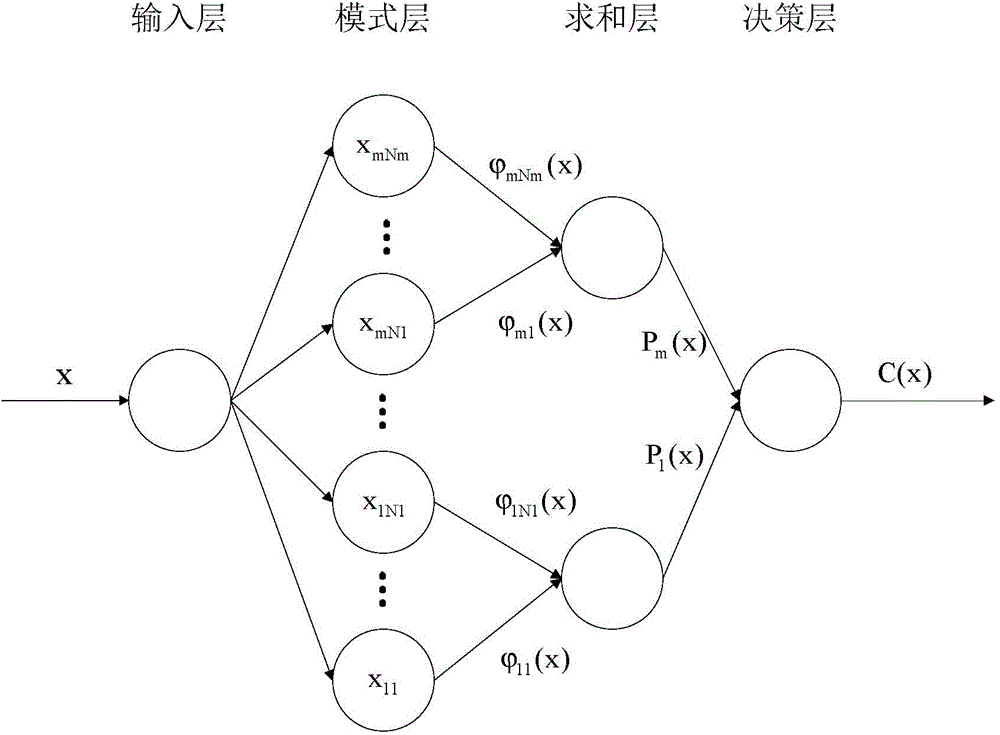

[0047] The first module is to extract the features of the thermal parameter data involved in the fault, and use the energy of each IMF component and trend margin as elements to construct the eigenvector of the original signal; the second module is to use the principal component analysis method to reduce the eigenvector matrix Dimension; the third module is to use the training samples to establish a probabilistic neural network, and to diagnose and identify the faults of the test samples.

[0048] The following is an illustration of the wear fault diagnosis results of the adjustment stage of a 600MW thermal power plant.

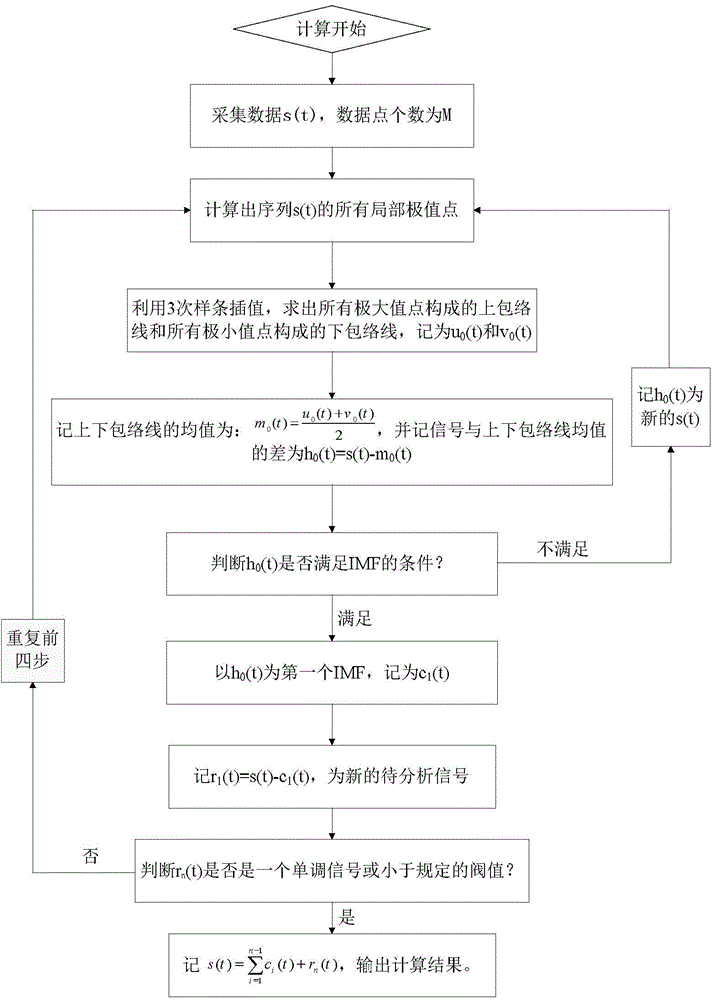

[0049] The first step of this method is to perform feature extraction on the thermal parameter data involved in the fault, and use the energy of each IMF component and trend margin as elements to construct the feature vector ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com