A method for measuring carrier concentration in solar-grade monocrystalline silicon

A carrier concentration, solar-level technology, applied in the direction of measuring devices, single semiconductor device testing, instruments, etc., can solve the problem of carrier mobility decline, achieve simple and fast measurement, reduce test cost, and high practical value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (1) Select a series of p-type electronic grade single crystal silicon as standard samples, the resistivity of the standard sample is 0.05-50Ω·cm, and the resistivity of the standard sample is evenly distributed in each resistivity range. The thickness of the standard sample is uniform, 1-2mm.

[0052] (2) After the standard samples are cleaned by the standard cleaning process, the resistivity of each sample is measured at room temperature according to the national standard "Method for Measuring the Resistivity of Silicon Single Crystal" (GB / T 1551-2009), and the resistance of each sample is measured by formula (5) The rate is converted to the corresponding carrier concentration.

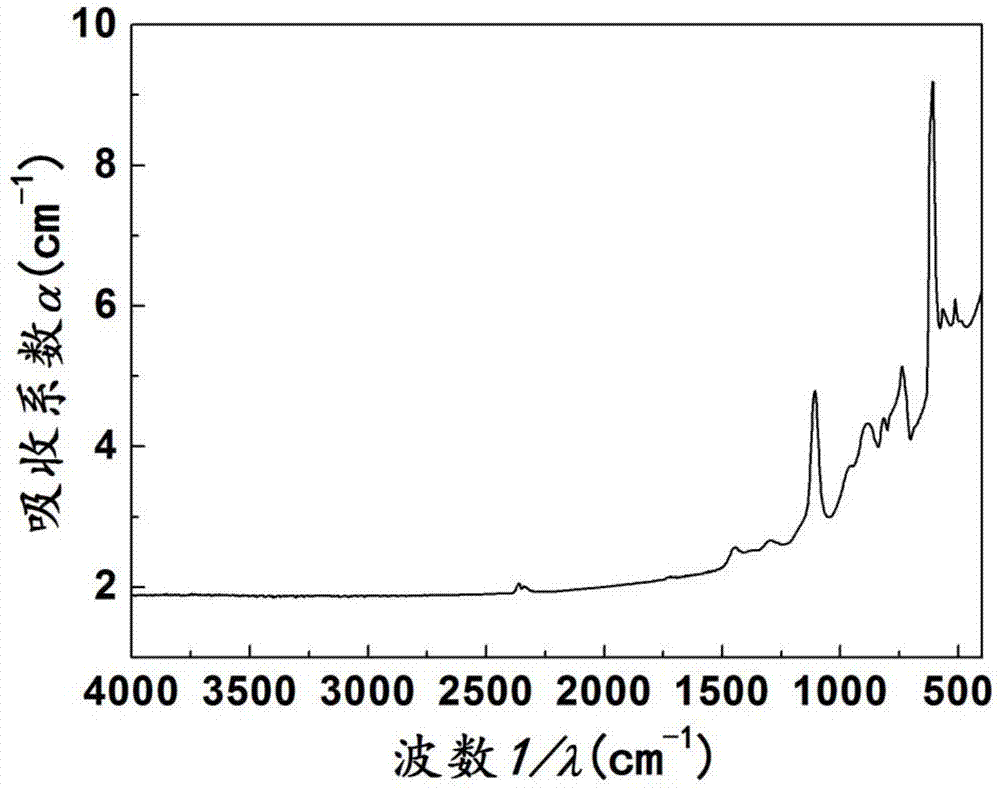

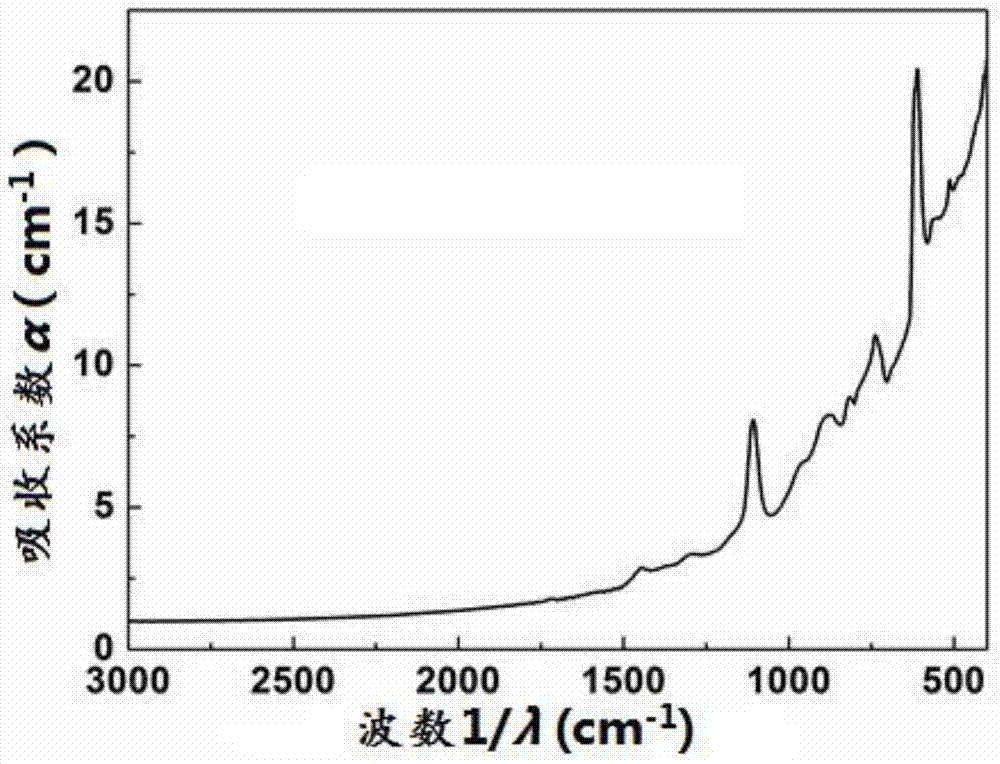

[0053] (3) The standard sample is chemically polished to make the two surfaces mirror-like, and after cleaning by standard cleaning process, the infrared transmission coefficient of each sample is measured by the Fourier Transform Infrared Spectrometer (FTIR) and converted into infrared by formula ...

Embodiment 2

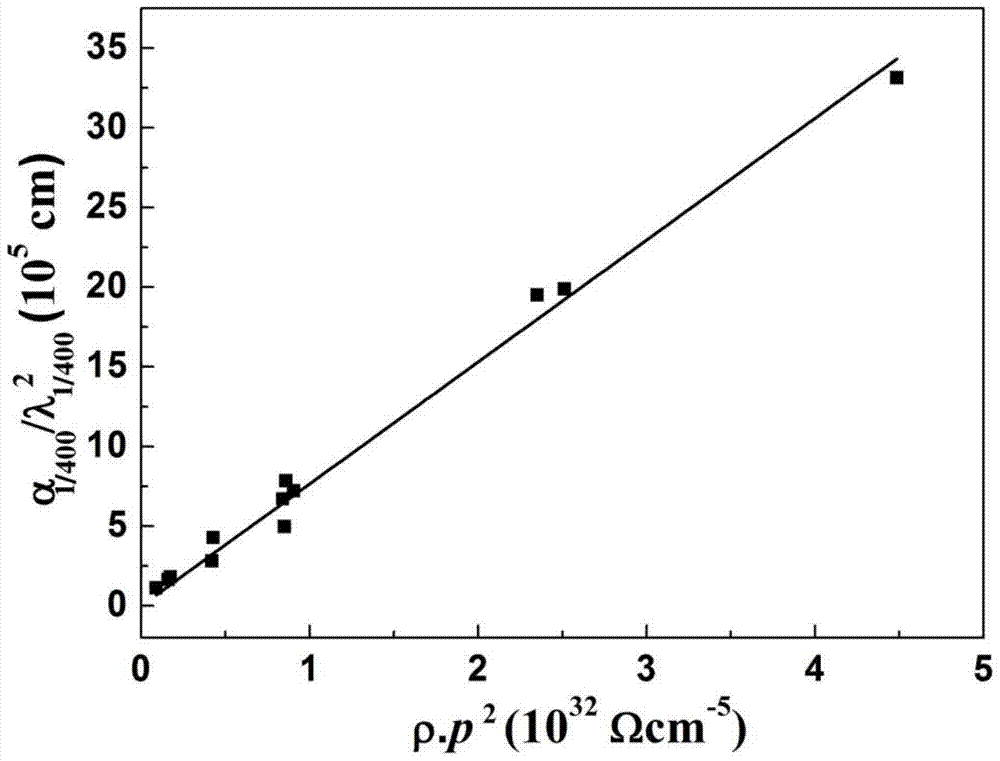

[0061] Steps (1) to (3) are the same as in Example 1. In step (4), the (α) of p-type single crystal silicon λ1 -α λ2 ) / (λ 1 2 -λ 2 2 ) And ρp 2 The standard curve, where: λ 1 = 1 / 400cm, λ 2 =1 / 1150cm, α λ1 With α λ2 Respectively wavelength λ 1 , Λ 2 The infrared absorption coefficient of the standard sample, such as Figure 4 As shown, the expression is: (α λ1 -α λ2 ) / (λ 1 2 -λ 2 2 )=(α 1 / 400 -α 1 / 1150 ) / (λ 2 1 / 400 - / λ 2 1 / 1150 )=7.9×10 -27 ρp (9)

[0062] For a certain boron-phosphorus-compensated solar-grade monocrystalline silicon sample to be tested in Example 1, the carrier concentration calculated according to formula (9) is 2.63×10 16 cm -3 . As a preferred method, the result is more accurate than Example 1.

[0063] It can be seen that the method of the present invention can be used to accurately measure the carrier concentration in solar-grade monocrystalline silicon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com