Gas turbine with exhaust gas diffuser and support ribs

A gas turbine and diffuser technology, which is applied in gas turbine installations, machines/engines, mechanical equipment, etc., can solve problems such as restricting the working mode of gas turbines and afterburners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

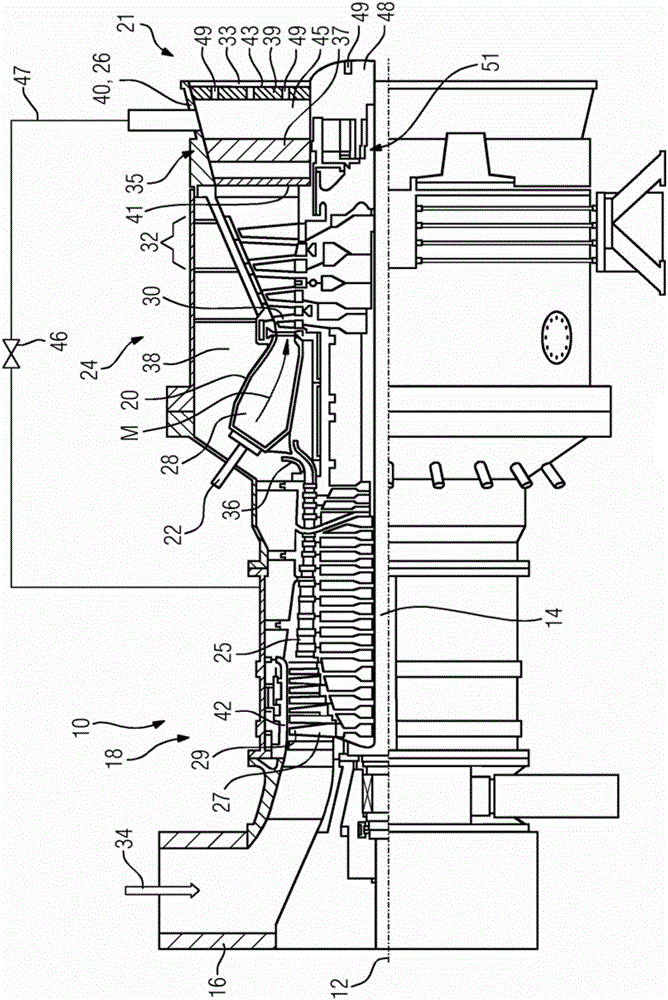

[0013] figure 1 A partial longitudinal section of a stationary gas turbine 10 is shown. The gas turbine 10 internally has a rotor 14 mounted in rotation about an axis of rotation 12 , which is also referred to as a turbine rotor. Along the rotor 14 are the suction housing 16 , the axial turbocompressor 18 , the toroidal annular combustion chamber 20 with a plurality of burners 22 arranged rotationally symmetrically to one another, the turbine unit 24 and the turbine exhaust housing 26. A turbine exhaust gas distributor, not shown in further detail, is connected to the turbine output housing 26 of the gas turbine 10 . These two components are part of the gas turbine exhaust diffuser 21 . Instead of an annular combustion chamber, the gas turbine can also be constructed with a plurality of tubular combustion chambers.

[0014] The axial turbocompressor 18 comprises a ring-shaped compressor channel with compression stages formed successively in cascade fashion in it, formed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com