Two-in-one back bending elbow

A two-in-one, bending technology, applied in the direction of elbows, pipes/pipe joints/fittings, branch pipelines, etc., can solve the problems of high weld cracking risk, affecting heat transfer effect, shortening the length of double pipes, etc., to achieve The effect of increasing wall thickness, increasing specific surface area, and extending the length of straight pipe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] In order to overcome the shortcomings of the "'Y-shaped two-in-one pipe fitting' (+ straight pipe) + 180° return bend" type two-in-one furnace tube structure and retain the existing advantages, the present invention uses a two-in-one return bend The head pipe connects two furnace tubes with one furnace tube, optimizes the furnace tube structure and fluid flow pattern, and improves the stress of the tube group.

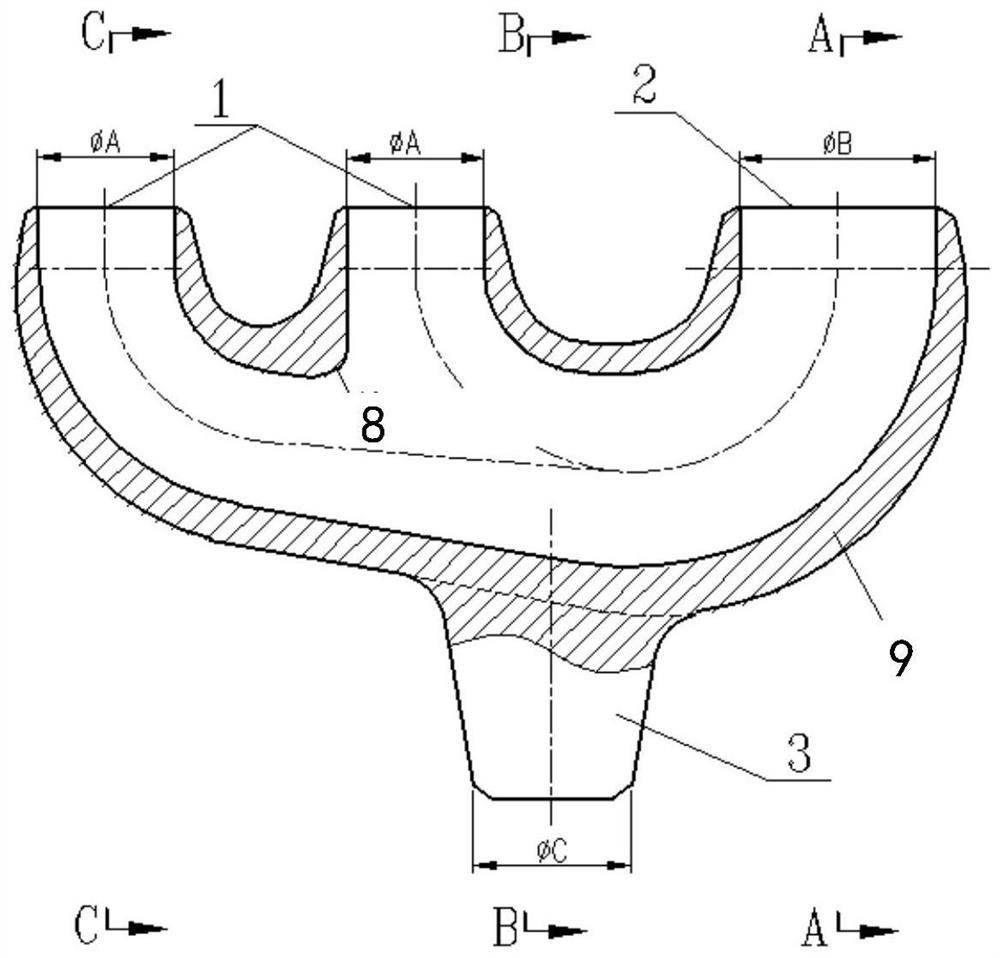

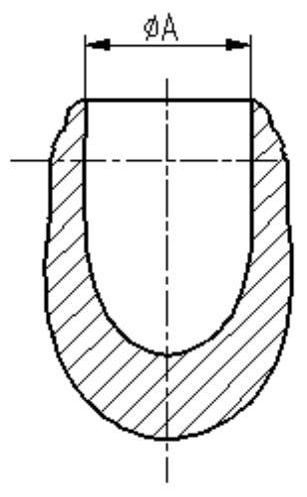

[0024] Such as Figure 1-Figure 6 As shown, the present invention provides a two-in-one back bending elbow with an integrated structure, which can be produced by casting, or by machining, 3D printing and other methods. Its main feature is that it has two inlet ports 1 and an outlet interface 2, the two inlet interfaces 1 are arranged adjacent to each other, and are set up with the outlet interface 2, the central axes of the two inlet interface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com