A gas phase feed diffuser

A diffuser and feed technology, applied in the field of internal components, can solve the problems of large pressure drop of gas-liquid diffuser, complex fluid shaping structure, uneven distribution of gas phase feed, etc., to achieve good buffering effect, good uniform distribution characteristics, Reduce the effect of shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

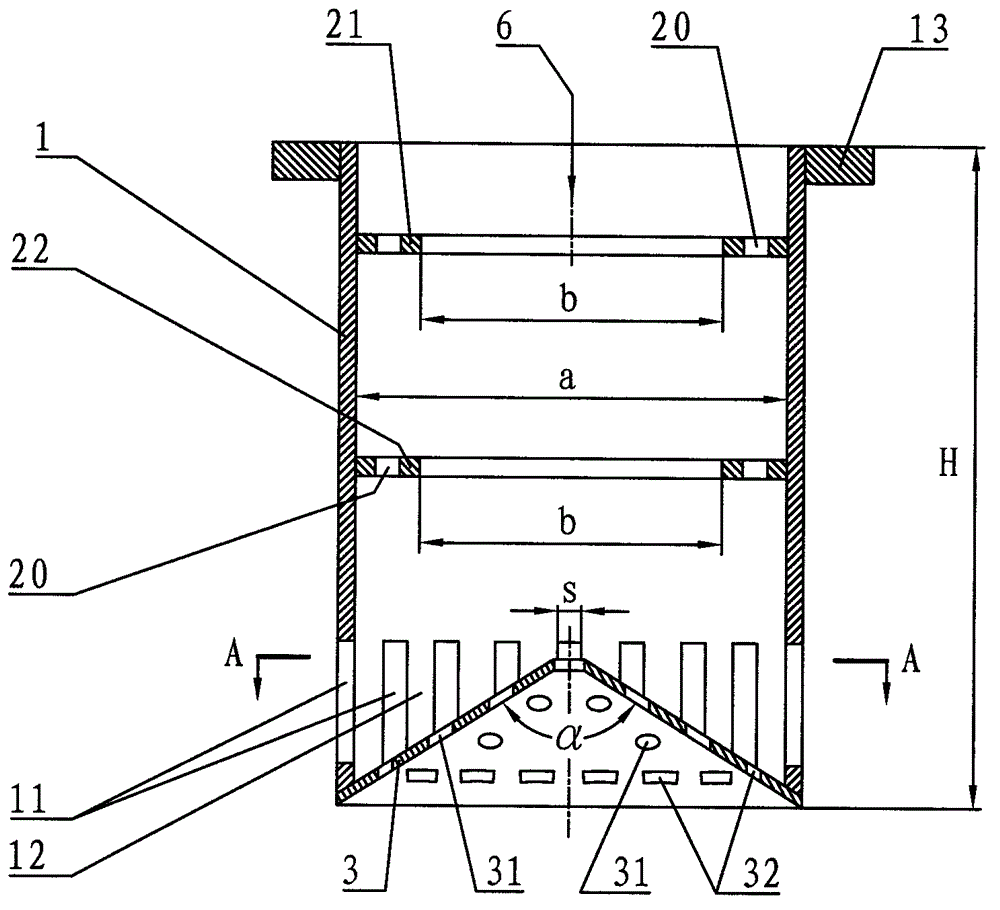

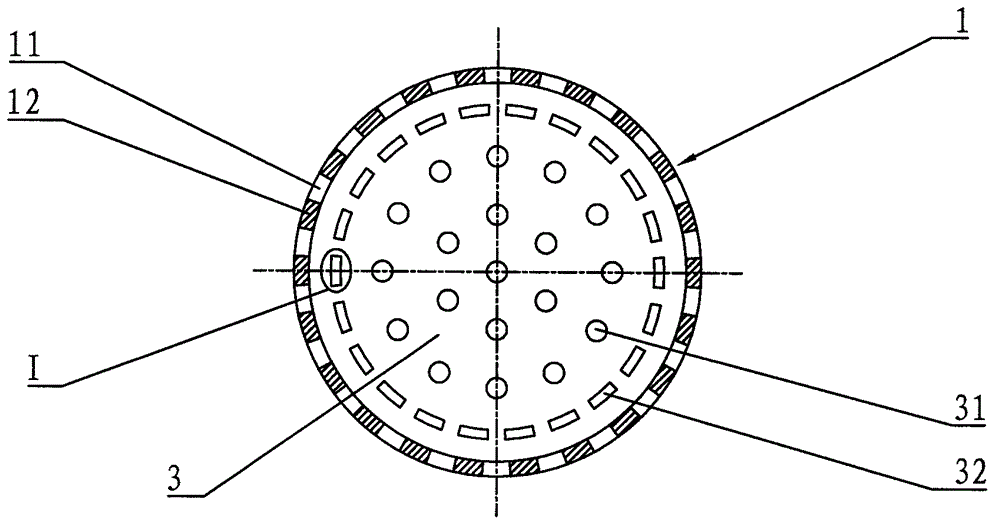

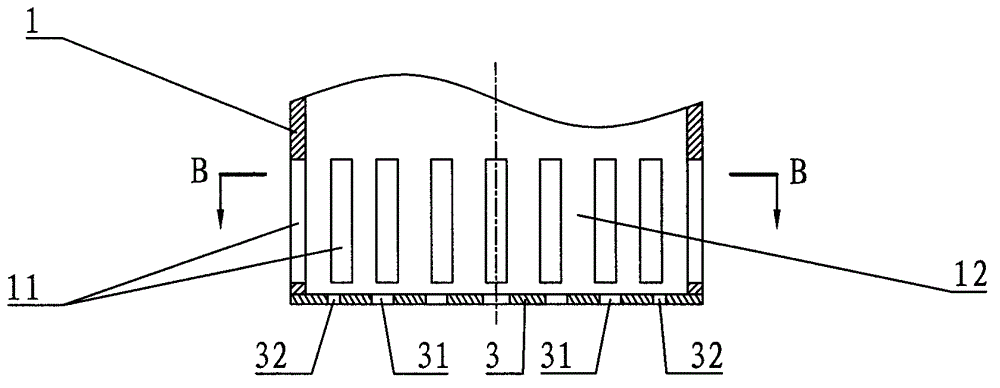

[0050] use figure 1 The shown gas phase feed diffuser (the inner circular hole on the upper shaping plate 21 and the inner circular hole on the lower shaping plate 22 are coaxial with the cylinder body 1 of the diffuser), in a small fixed bed reactor (referred to as reaction The cold mold test was carried out on the device), and the test temperature was 25°C. The reactor is provided with a cylindrical body and a top head; the inlet is located on the top head, and the bottom of the cylindrical body is an open structure. The overall height of the reactor is 4000 mm, the inner diameter of the cylindrical reactor body is 1000 mm. The diffuser is installed at the inlet of the reactor, inside the top head of the reactor. See Figure 8 . The materials of the components of the diffuser, the reactor and the intake pipe are all plexiglass.

[0051]The inner diameter a of the diffuser cylinder 1 is 186 mm, and the overall height H of the diffuser is 390 mm. The vertical distance fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com