Clamping device for automatic tin dipping machine

A technology of clamping device and tin dipping machine, which is applied in auxiliary devices, metal processing, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

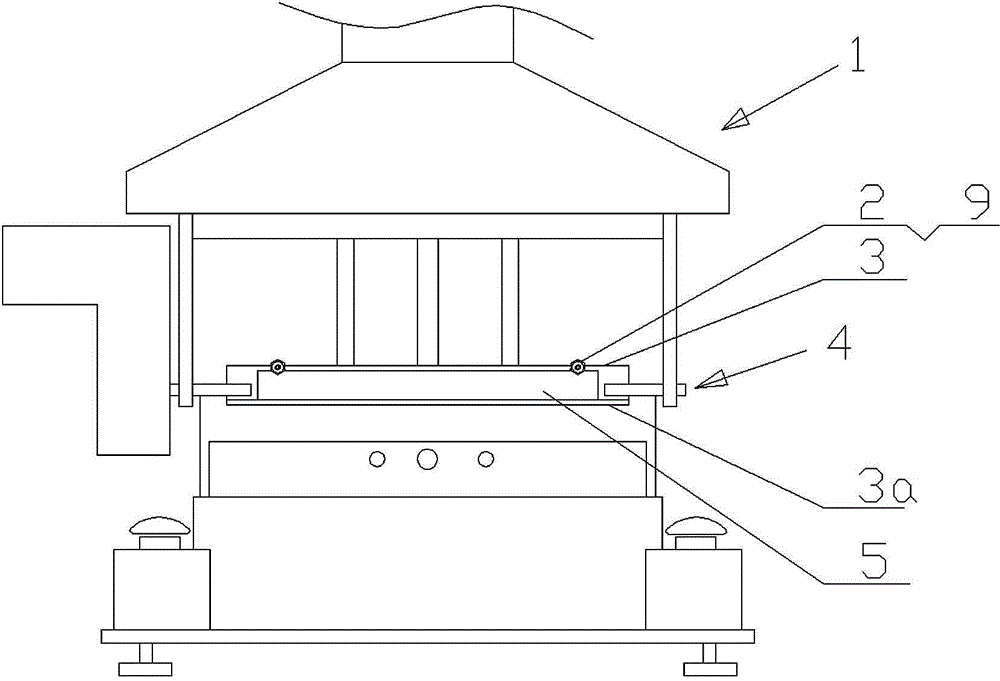

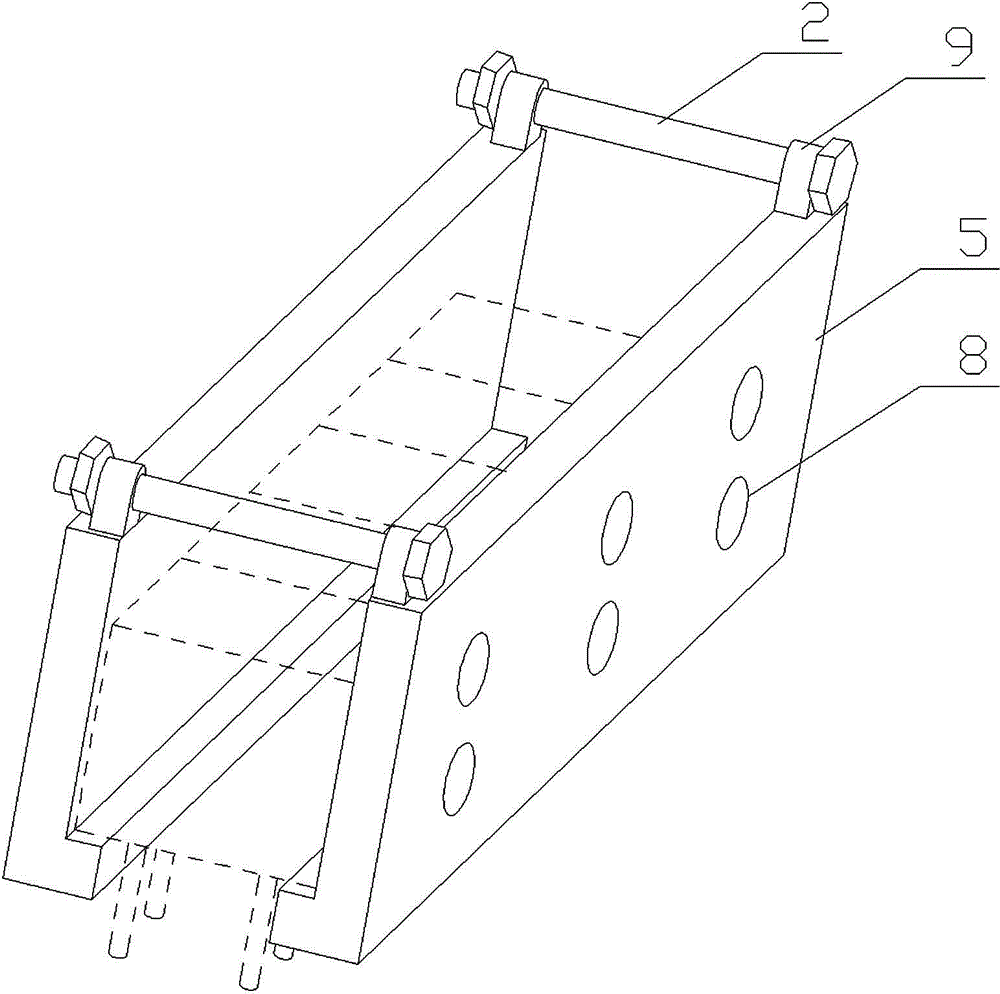

[0017] Such as figure 1 and figure 2 As shown, a clamping device for an automatic tin dipping machine provided by the present invention includes a jaw mechanism 4 arranged on the body 1 of the tin dipping machine. A positioning boss 3a is provided along its horizontal direction, and two symmetrically arranged L-shaped splints 5 are arranged on the positioning boss. A connecting seat 9 is respectively arranged at a symmetrical position on the top of each splint, and the connecting seats corresponding to the L-shaped splint pass through The adjusting bolts 2 are matched and connected, and one side of one of the L-shaped splints is adsorbed on the turnover plate by a group of powerful magnets 8 .

Embodiment 2

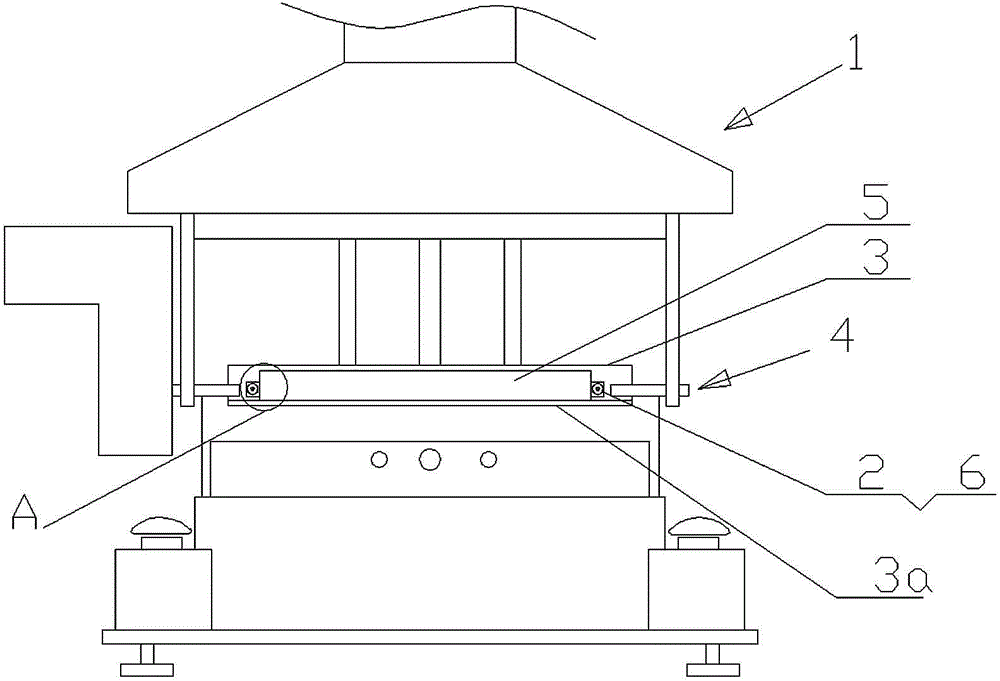

[0019] Such as image 3 , Figure 4 and Figure 5 As shown, a clamping device for an automatic tin dipping machine provided by the present invention includes a jaw mechanism 4 arranged on the body 1 of the tin dipping machine. A positioning boss 3a is provided along its horizontal direction, and two symmetrically arranged L-shaped splints 5 are arranged on the positioning boss. Both sides of each L-shaped splint are respectively provided with chute 5a, and a pair of ball springs 7 are arranged at the bottom of the chute. , there is a sliding block 6 in the chute, the bottom of the sliding block is provided with a limit groove 6a that cooperates with the ball spring, and the sliding blocks 6 corresponding to the splint 5 are connected by adjusting bolts 2, and one of the L One side of the splint is adsorbed on the turnover plate 3 by a group of powerful magnets 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com