Laser machining machine table and correction method thereof

A laser processing machine, laser processing technology, used in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of waste, correction of steel plates that cannot be used for other purposes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

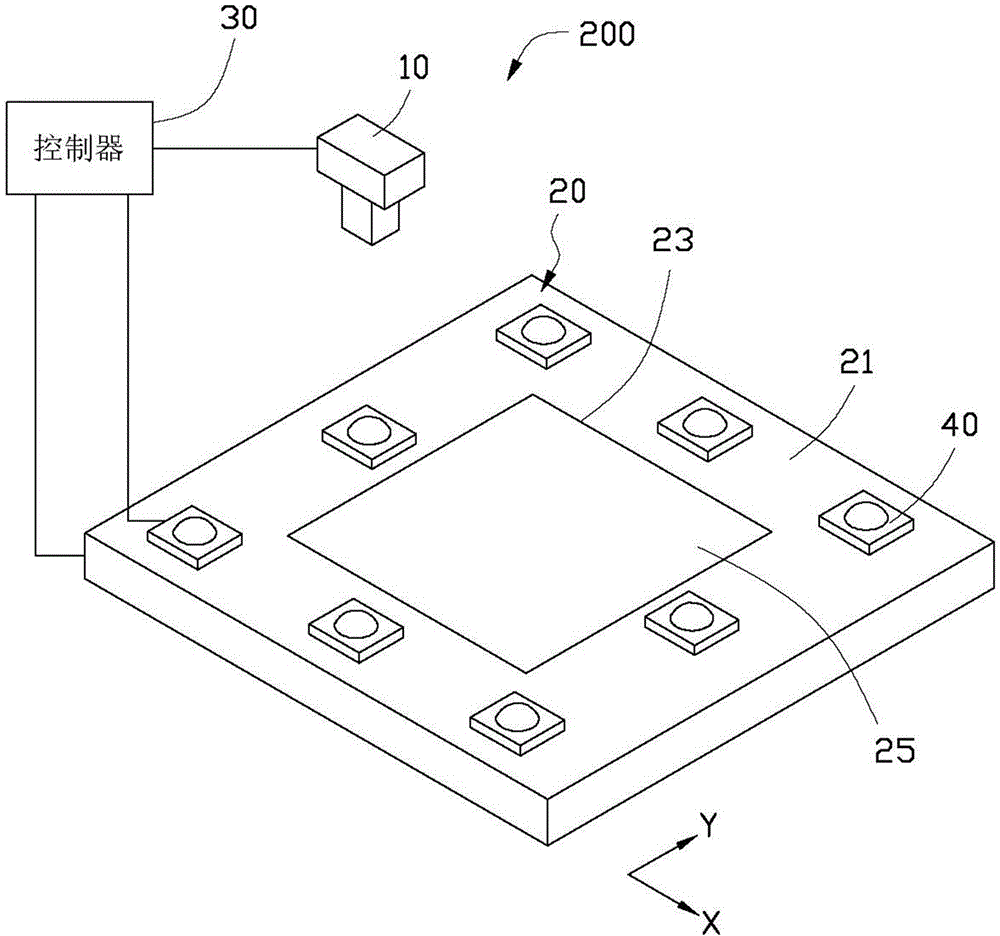

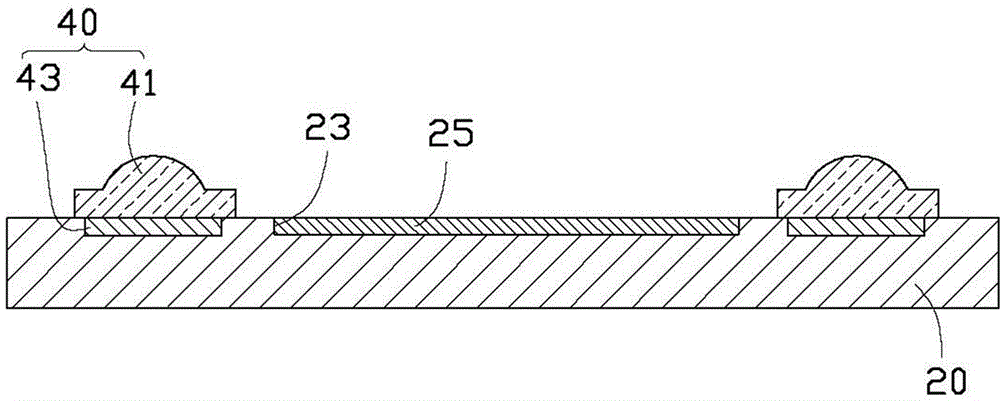

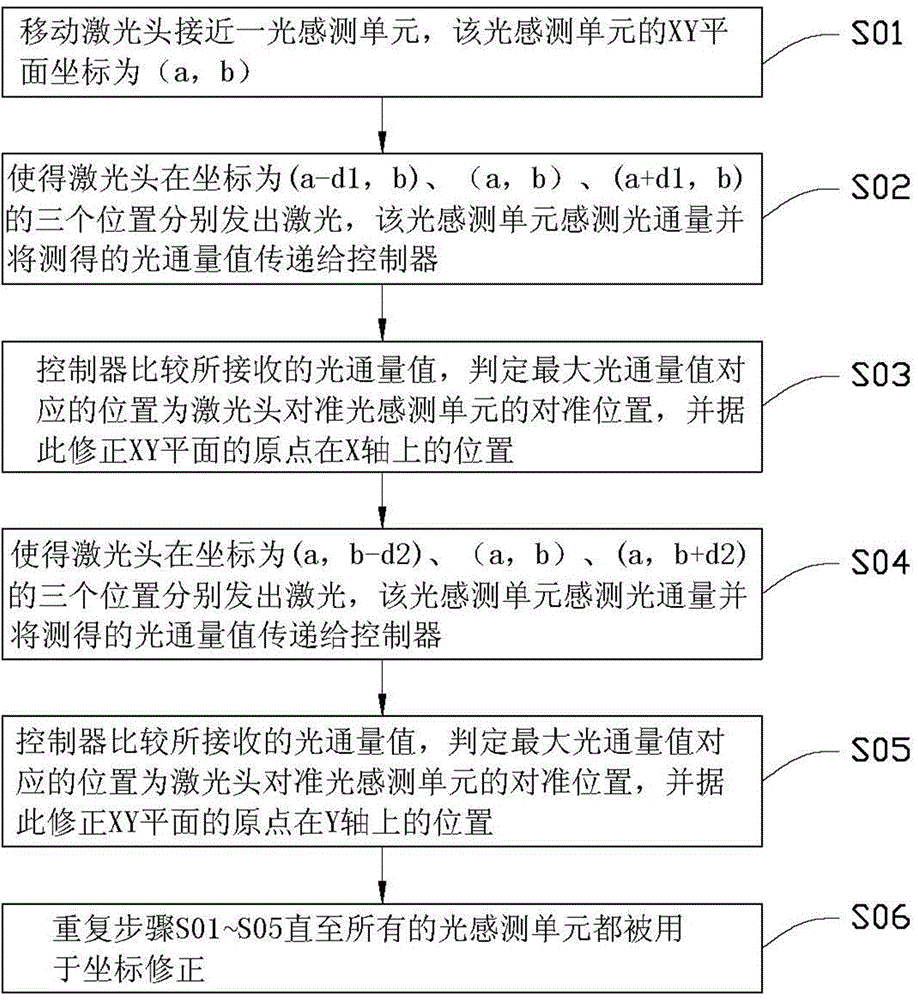

[0021] see figure 1 , figure 2 , which discloses a laser processing machine 200 according to an embodiment of the present invention. The laser processing machine 200 includes a laser head 10 , a carrying unit 20 , a controller 30 , and at least one light sensing unit 40 .

[0022] The bearing unit 20 includes a bearing surface 21, and a bearing hole 23 is formed on the bearing surface 21. In this embodiment, both the bearing surface 21 and the bearing hole 23 are square, and the bearing hole 23 is located at the center of the bearing surface. Location. The carrying hole 23 is used to accommodate and fix a mold core 25 to be processed.

[0023] The laser head 10 is located above the carrying unit 20, the laser head 10 is used to emit laser light, the controller 30 is used to control the laser head 10 to move along a predetermined path, and control the laser head 10 to emit laser light at a predetermined position, thereby Complete dot processing on the die core 25 to be pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com