Preparation method of carbon fiber/graphene oxide/organic silicon resin multidimensional hybrid composite material

A composite material and carbon fiber technology, applied in the field of nanomaterials, can solve the problems of poor mechanical properties, poor wettability of matrix resin, and low interface bonding strength, and achieve the effects of easy operation, improved interface bonding strength, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1. Preparation of graphite oxide: put a three-necked flask containing 4g of nano-graphite into an ice-water bath, and slowly add 9gKMnO 4 and 200mL concentrated H 2 SO 4 / H 3 PO 4 Mixed solution (v:v=9:1), mechanically stirred for 1h to make it fully mixed; then heated up to 50°C for 15h, after the reaction was completed, 800mL of distilled water was added dropwise, and then 15mL of 30% H 2 o 2 , the solution gradually turned bright yellow, washed repeatedly with 5% dilute HCl and distilled water, and centrifuged until the filtrate was nearly neutral. Vacuum drying at 60°C to obtain graphite oxide;

[0020] 2. Preparation of graphene oxide: weigh 0.37g of graphite oxide and add it to 100mL of distilled water, ultrasonically oscillate for 30 minutes with the probe of an ultrasonic pulverizer, then centrifuge at 11000r / min with a centrifuge, and vacuum dry at 60°C to obtain graphene oxide powder;

[0021] 3. Aminopropyl alkylation treatment of graphene oxide: immer...

Embodiment 2

[0032] 1. Preparation of graphite oxide: put a three-neck flask containing 8g nano-graphite into an ice-water bath, slowly add 18gKMnO 4 and 400mL concentrated H 2 SO4 / H 3 PO 4 Mixed solution (v:v=9:1), mechanically stirred for 1h to make it fully mixed; then heated up to 50°C for 15h, after the reaction, 800mL of distilled water was added dropwise, and then 30mL of 30% H 2 o 2 , the solution gradually turned bright yellow, washed repeatedly with 5% dilute HCl and distilled water, and centrifuged until the filtrate was nearly neutral. Vacuum drying at 60°C to obtain graphite oxide;

[0033] 2. Preparation of graphene oxide: weigh 3.74g of graphite oxide and add it to 500mL of distilled water, ultrasonically oscillate for 30 minutes with the probe of an ultrasonic pulverizer, then centrifuge at 11000r / min with a centrifuge, and vacuum dry at 60°C to obtain graphene oxide powder;

[0034] 3. Aminopropyl alkylation treatment of graphene oxide: immerse 1g of graphene oxide i...

PUM

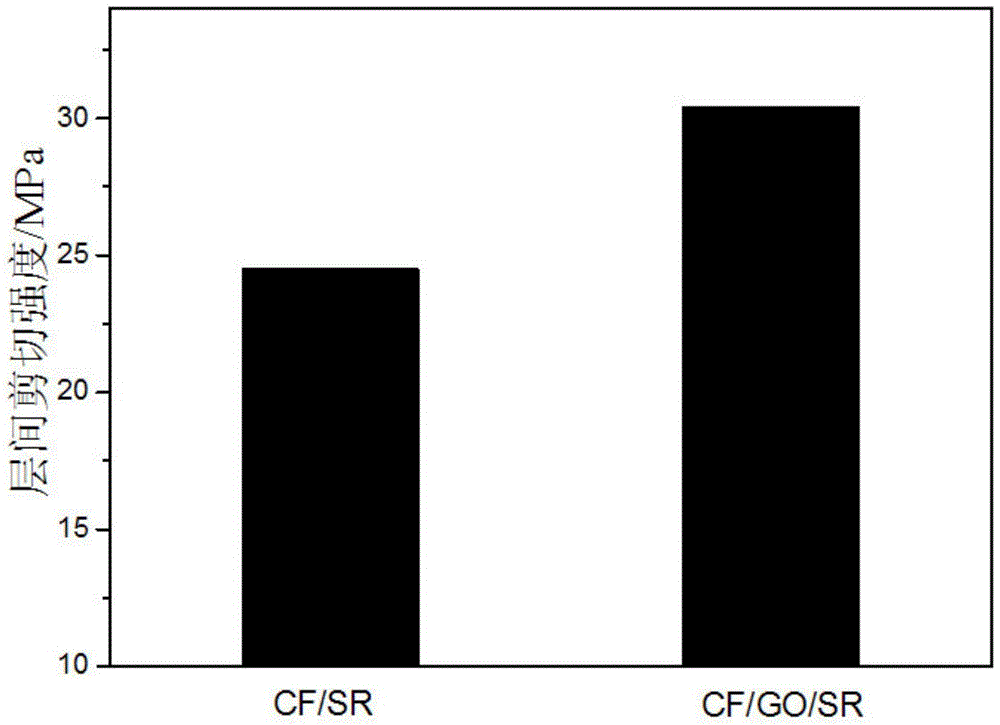

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com