A kind of precipitation method silica surface modification method

A technology of precipitation silica and surface modification, which is applied in the field of silica, can solve the problems of chemical reagent pollution, carbon layer is easy to fall off, etc., and achieve the effect of improving dispersion performance, improving balance performance, and facilitating constant temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

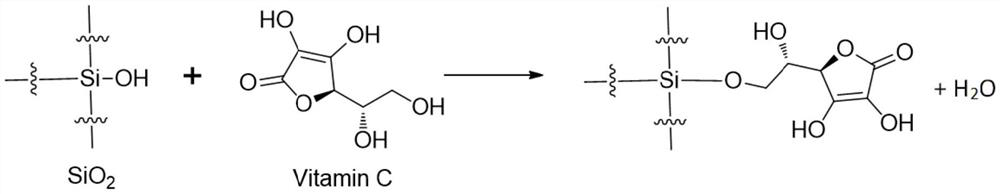

Method used

Image

Examples

Embodiment 1

[0020] The modification steps of the white carbon black in the present embodiment are as follows,

[0021] (1) Mixing, add the white carbon black powder powder prepared by the precipitation method to 200 mesh and 300 mesh vitamin C powder in a mass ratio of 1:1 to the mixer for mixing. The mixing time is 30 minutes. After mixing, transfer the mixture into the ball mill.

[0022] (2) Ball milling reaction, the reaction temperature is 25° C., the ball mill speed is 230 r / min, and the ball milling time is 2 hours. During the reaction process, dry nitrogen gas was introduced at a rate of 40 ml / min to take away the moisture generated during the ball milling process.

[0023] (3) Heating and carbonization. After the ball milling reaction, transfer the ball milled product to the reactor, and introduce hot air for carbonization reaction. The temperature of the hot air is 200°C, the flow rate is 190ml / min, and the heating time is 2.5h. When the temperature is lowered to room temperat...

Embodiment 2

[0025] The modification steps of the white carbon black in the present embodiment are as follows,

[0026] (1) Mixing, add the white carbon black powder powder prepared by the precipitation method to 100 mesh and add 200 mesh vitamin C powder to the mixer at a mass ratio of 1:0.8 for mixing. The mixing time is 30 minutes. After mixing, transfer the mixture into the ball mill.

[0027] (2) Ball milling reaction, the reaction temperature is 60° C., the ball mill speed is 270 r / min, and the ball milling time is 2 hours. During the reaction process, dry nitrogen gas was introduced at a rate of 60 ml / min to take away the moisture generated during the ball milling process.

[0028] (3) Heating carbonization. After the ball milling reaction is over, the ball milling product is transferred to the reactor, and hot air is introduced to carry out the carbonization reaction. The temperature of the hot air is 230° C., the flow rate is 190ml / min, and the heating time is 2 hours. After rea...

Embodiment 3

[0030] The modification steps of the white carbon black in the present embodiment are as follows,

[0031] (1) Mixing, add the white carbon black powder powder prepared by the precipitation method to 100 mesh and add 200 mesh vitamin C powder to the mixer at a mass ratio of 1:0.9 for mixing. The mixing time is 30 minutes. After mixing, transfer the mixture into the ball mill.

[0032] (2) Ball milling reaction, the reaction temperature is 40° C., the ball mill speed is 250 r / min, and the ball milling time is 3 hours. During the reaction process, dry nitrogen gas was introduced at a rate of 50 ml / min to take away the moisture generated during the ball milling process.

[0033] (3) Heating carbonization. After the ball milling reaction is over, the ball milling product is transferred to the reactor, and hot air is introduced for carbonization reaction. The temperature of the hot air is 230°C, the flow rate is 240ml / min, and the heating time is 2h. After reaching room temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com