A nitrogen-doped carbon-coated magnetic nanoparticle composite microsphere and its preparation method

A magnetic nanoparticle, nitrogen-doped carbon technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as complex synthesis technology, achieve easy aggregation, absorption frequency bandwidth, Effects that are easy to prepare in large quantities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

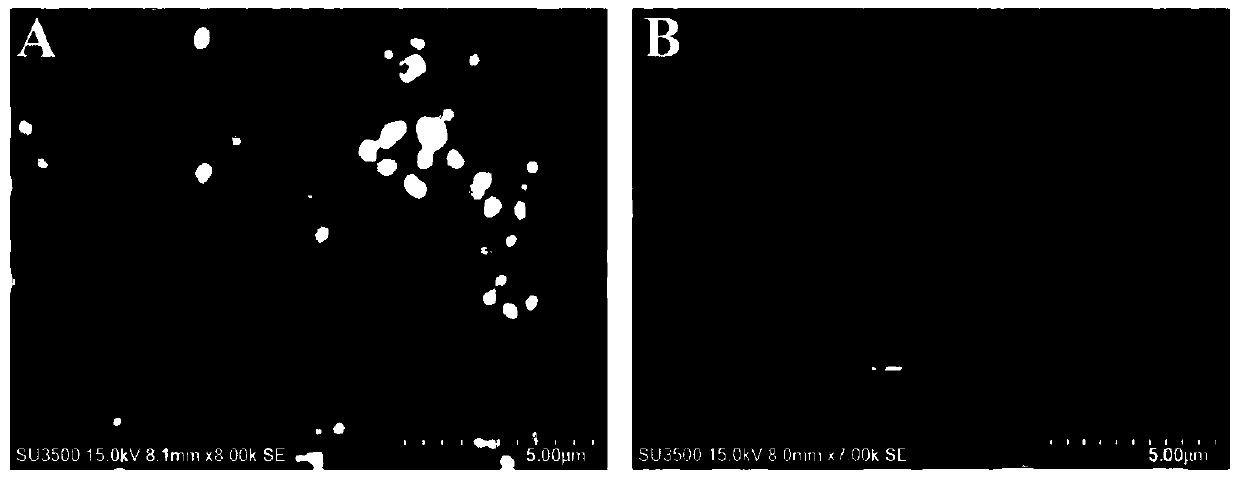

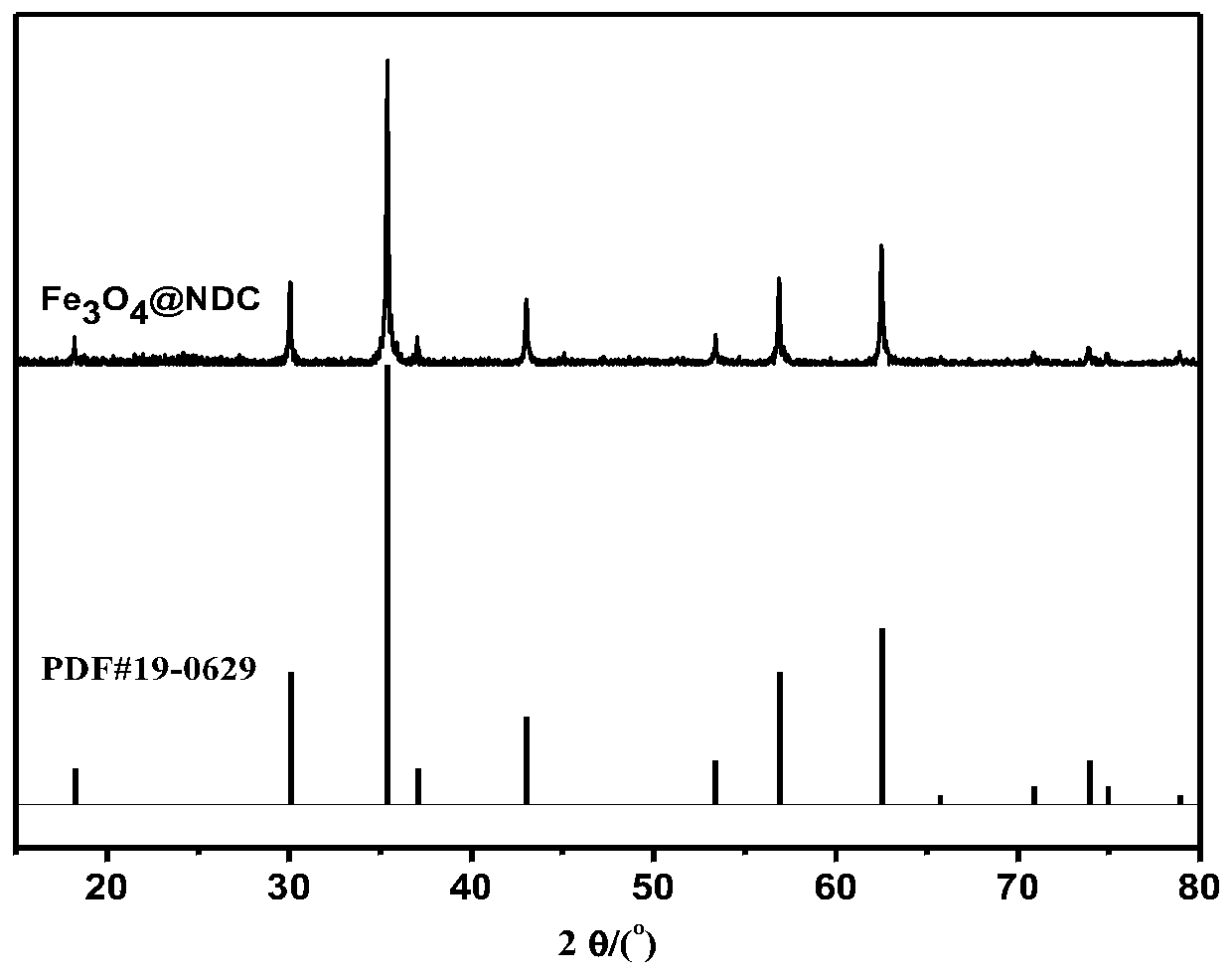

Embodiment 1

[0030] Step 1: Measure 15ml of glycerin into a beaker filled with 85ml of isopropanol, and stir well. Weigh 0.404g Fe(NO) 3 9H 2 O was added to the above solution, stirred under ultrasonic conditions for 10 min, then poured into a reaction kettle, and reacted at a reaction temperature of 200° C. for 12 h. After the reaction, the product was centrifuged and washed with alcohol several times, and the washed solid product was dried in an oven at a drying temperature of 70°C to finally obtain the iron glycerol precursor.

[0031] Step 2: Dissolve 1.0g of PEG-800 in 100ml of water, transfer the solution into a 250ml three-necked flask, then weigh 0.1g of the iron glycerol precursor in step 1 and add it, and continue stirring for 1h under ultrasonic conditions to form Uniform suspension; slowly inject 0.1g of pyrrole into the above system, and after stirring for 1h, slowly add 15ml of 0.2mol / L FeCl prepared in advance dropwise 3 Solution, continue to react for 2h, after the react...

Embodiment 2

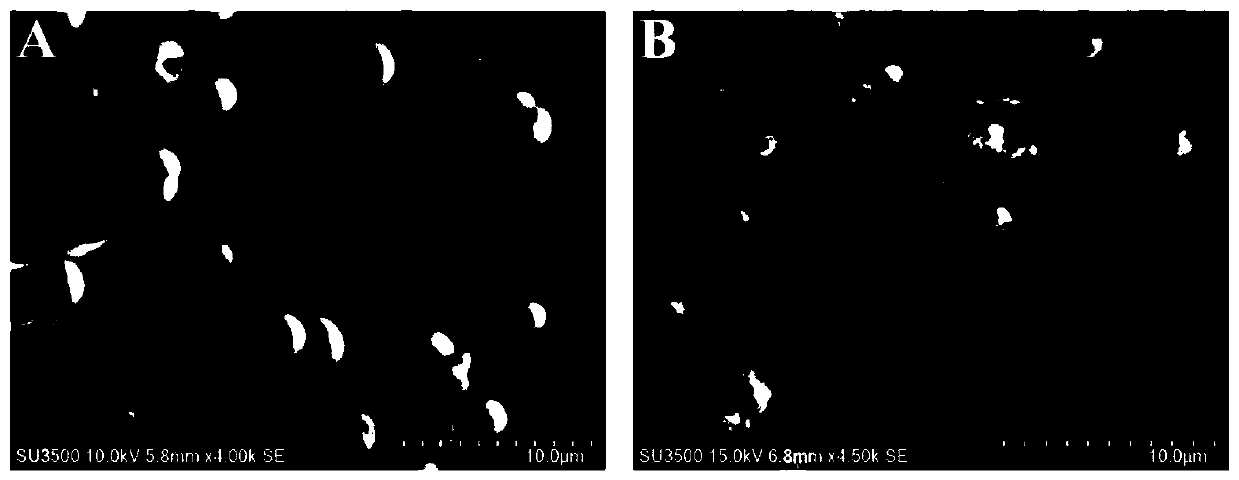

[0036] Step 1: Measure 5ml of glycerin into a beaker filled with 25ml of isopropanol, and stir well. Weigh 0.200g of cobalt oxalate and add it to the above solution, stir for 10 minutes under ultrasonic conditions, pour it into a reaction kettle, and react at a reaction temperature of 120° C. for 16 hours. After the reaction, the product was centrifuged and washed with alcohol several times, and the washed solid product was dried in an oven at a drying temperature of 60°C to finally obtain the cobalt glycerol precursor.

[0037] Step 2: Measure 0.5g of polyvinylpyrrolidone (PVP) and dissolve it in 100ml of water, transfer the solution into a 250ml three-neck flask, then weigh 0.15g of the iron glycerol precursor in step 1 and add it, and continue stirring under ultrasonic conditions 0.5h until a uniform suspension is formed; slowly inject 0.15g of aniline into the above system, and after stirring for 2h, slowly add 10ml of 0.1mol / L ammonium persulfate solution prepared in adva...

Embodiment 3

[0039] Step 1: Measure 25ml of glycerin into a beaker filled with 200ml of isopropanol, and stir well. Weigh 0.5g of ferric nitrate and 0.5g of cobalt nitrate and add to the above solution, stir for 10min under ultrasonic conditions, pour into the reaction kettle, and react at the reaction temperature of 160°C for 6h. After the reaction, the product was centrifuged and washed with alcohol several times, and the washed solid product was dried in an oven at a drying temperature of 80°C to finally obtain the iron-cobalt glycerol precursor.

[0040] Step 2: Take 2.0g of cetyltrimethylammonium bromide (CTAB) and dissolve it in 100ml of water, transfer the solution into a 250ml three-neck flask, then weigh 0.2g of the glycerol iron cobalt precursor in step 1 and add it , under ultrasonic conditions, continue to stir for 1.5h to form a uniform suspension; slowly inject 0.4g of pyrrole into the above system, and after stirring for 1h, slowly add 15ml of 0.4mol / L hydrogen peroxide solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com