A CO-shift process that can prolong the service life of catalysts

A technology for prolonging the life of catalysts, applied in the field of CO conversion technology, can solve the problems of reducing the service life of catalysts, and achieve the effects of avoiding reaction overtemperature, simple and reliable adjustment methods, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

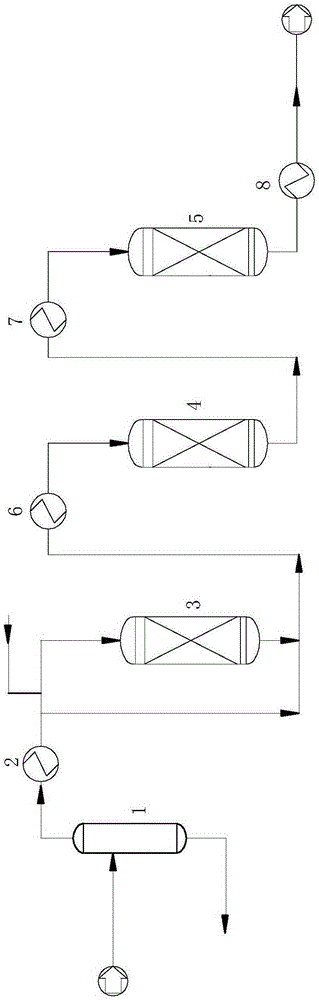

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0016] Such as figure 1 As shown, the CO shift process that can prolong the service life of the catalyst is used in conjunction with the coal gasification unit.

[0017] The dry basis concentration of CO in the crude gas from the coal gasification device is 72v%. It first enters the gas-liquid separator 1 to separate the liquid phase, and then enters the first heat exchanger 2 for heat exchange.

[0018] The crude synthesis gas after heat exchange is divided into two streams.

[0019] When the catalyst in the first shift furnace is a fresh catalyst, for example, at the beginning of the plant or when the catalyst is just replaced, the activity is very high, resulting in a very fast shift reaction speed and a high reaction depth in the first shift furnace, and the CO conversion rate can reach More than 88%. The flow ratio of the first crude g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com