Braiding method of variable cross section structure rope fabric, and braiding machine

A cross-sectional structure and weaving machine technology, applied in the direction of braided fabrics, textiles and papermaking, etc., can solve the problems of less color changes, single structure, and difficulty in meeting market demand, and achieve the effect of meeting market demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

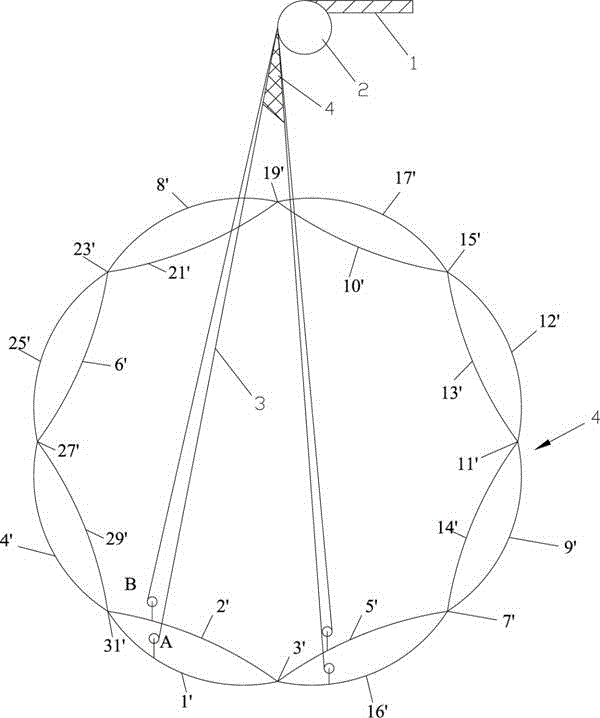

[0022] Such as figure 2 As shown, the embodiment of the present invention provides a weaving method for weaving a rope fabric with a triangular cross-section with floats and a circular cross-section.

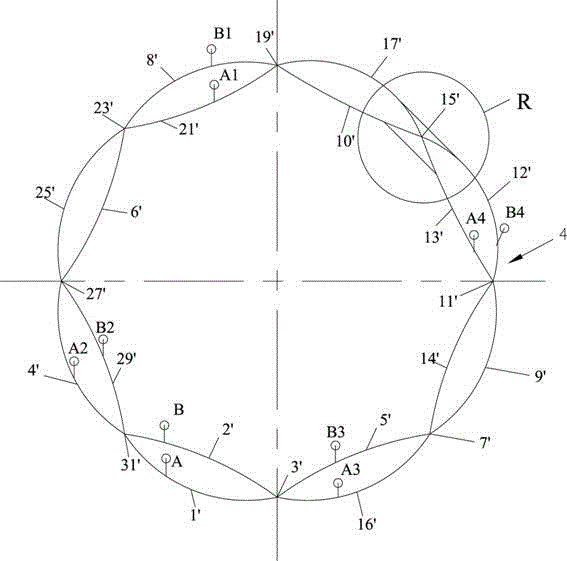

[0023] step 1. The ordinary knitting machine is transformed, and four yarn seat groups are evenly installed on the yarn seat track 4 of the knitting machine, and the yarn seat track 4 is divided into four sub-tracks, and the yarn seat group includes a yarn seat A and a yarn seat B, Each group of yarn seats wears the same yarn, the first group of yarn seats A1 and B1, the second group of yarn seats A2 and B2, the third group of yarn seats A3 and B3, and the fourth group of yarn seats A4 and B4.

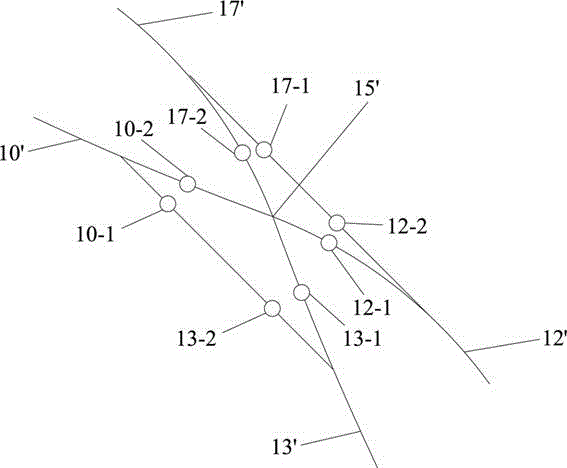

[0024] Step 2. Such as image 3 As shown, one of the sub-tracks is modified, an optional track is set, and a movable block is installed on the optional track. The movable block can be driven by a stepping motor to rise and fall according to the instructions of the programmable contro...

Embodiment 2

[0028] Such as figure 2 As shown, the embodiment of the present invention provides a weaving method for weaving rope fabrics with triangular cross-sections and floating threads and quadrilateral cross-sections.

[0029] Step 1, Step 2, and Step 3 are the same as those in Embodiment 1.

[0030] Step 4. When weaving a quadrilateral section, the first group of yarn seats A1 and B1, the second group of yarn seats A2 and B2, the third group of yarn seats A3 and B3, and the fourth group of yarn seats A4 and B4 are on their respective sub-tracks Rotate 91 o around the center of the yarn seat track 4 and return, and circulate several times according to the length of the rope section of the required quadrilateral section.

Embodiment 3

[0032] Such as figure 2 As shown, the embodiment of the present invention provides a weaving method for weaving rope fabrics with triangular cross-sections with floating threads, circular cross-sections and quadrilateral cross-sections.

[0033]Step 1 and Step 2 are the same as in Embodiment 1.

[0034] Step 3. When weaving the rope segment with quadrilateral section, the first group of yarn seats A1 and B1, the second group of yarn seats A2 and B2, the third group of yarn seats A3 and B3, and the fourth group of yarn seats A4 and B4 are wound on their respective sub-tracks. Yarn seat track 4 center rotation 91o promptly returns, and circulates several times according to the rope section length of required quadrilateral section.

[0035] Step 4. Such as figure 2 with image 3 As shown, when weaving the rope segment of triangular section, the first group of yarn seats A1 and B1, the second group of yarn seats A2 and B2, the third group of yarn seats A3 and B3, and the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com