Reinforced concrete stop log gate sealing method

A technology of reinforced concrete and stacked beam gates, which is applied in water conservancy projects, sea area projects, coastline protection, etc. It can solve the problems of large water leakage, incomplete joint joints, and high investment in steel gates, so as to improve water leakage problems and better blockage effect, the effect of low material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0019] A water-stopping method for a reinforced concrete stacked beam gate, comprising the following steps:

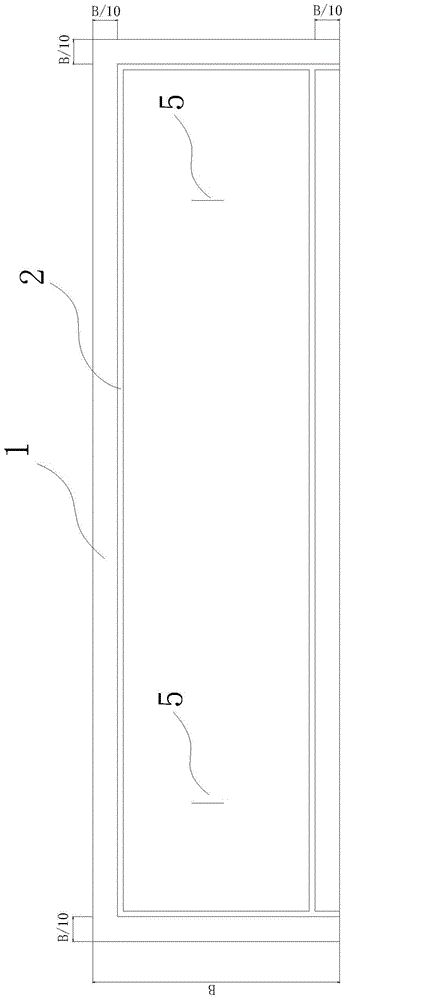

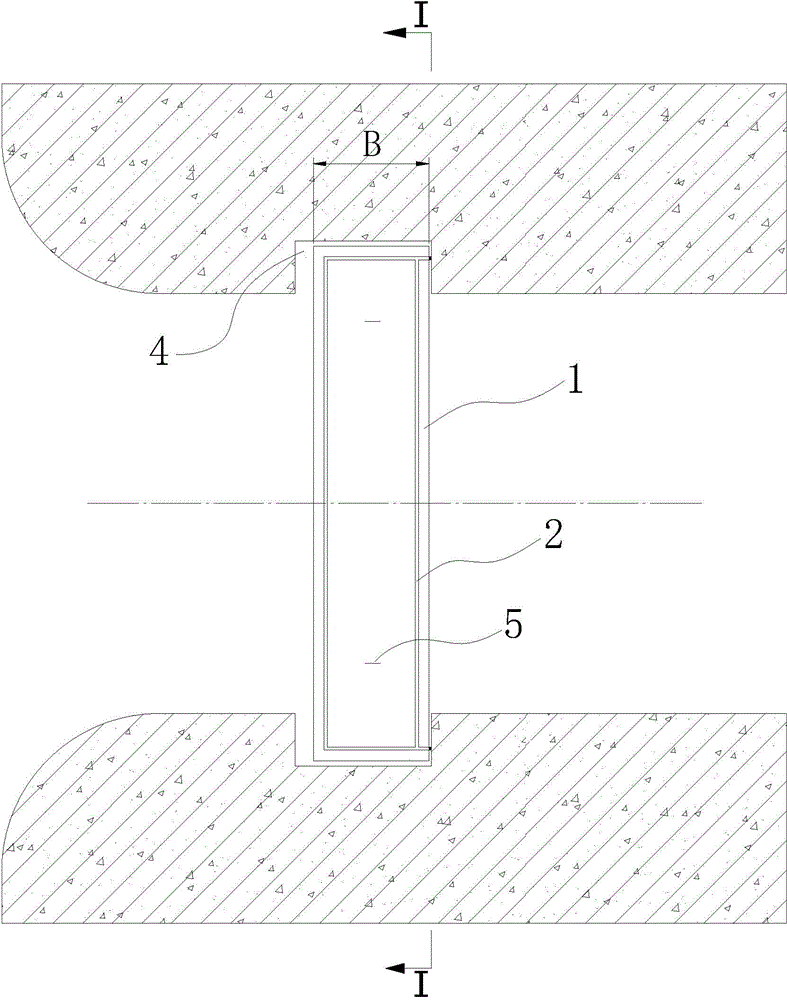

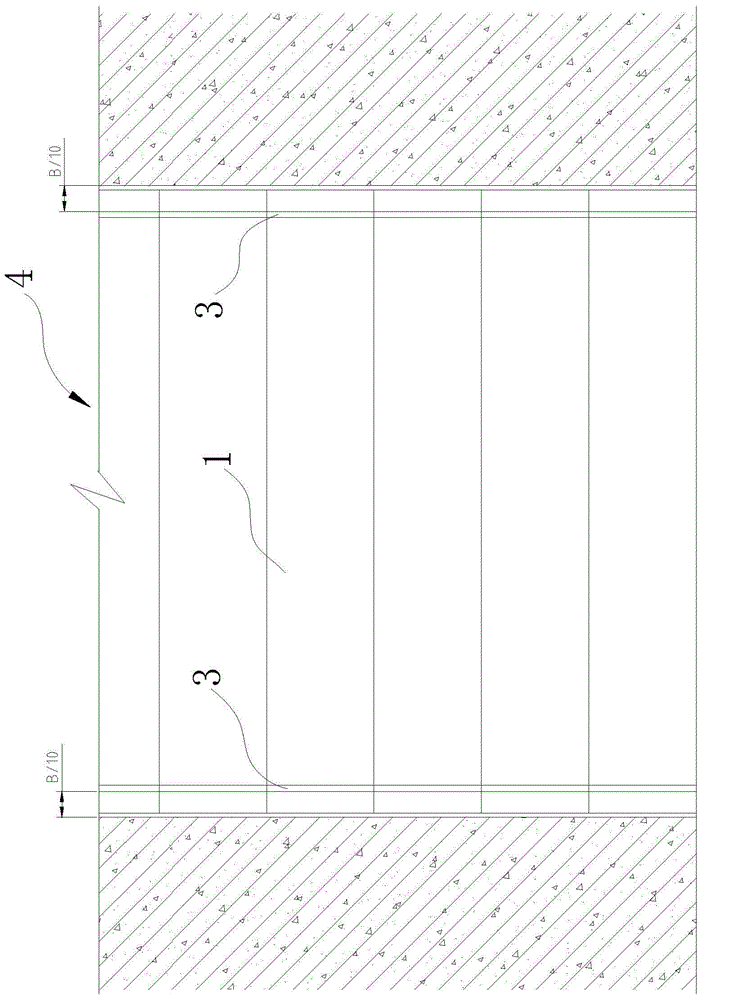

[0020] Step 1: Clean the surface of the stacking beam 1, and attach rubber water-stop strips to the surface of the stacking beam 1 at a distance of B / 10 from the surrounding edges (set the width of the stacking beam as B), so as to form a closed circle of horizontal water-stop strips 2;

[0021] First, clean the outer surface of the stacking beam 1, and trim the pockmarked or uneven parts to make them clean and free of debris. In a preferred embodiment, the rubber water-stop strip adopts a regular rubber water-stop strip with a specificat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com