Loader bucket

A loader and bucket technology, applied in the field of buckets, can solve the problems of large shovel entry resistance and low shovel loading efficiency, and achieve the effects of increasing bucket capacity, improving shovel loading efficiency, and improving connection reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

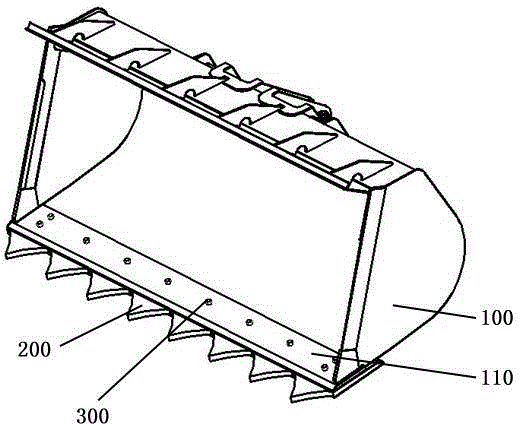

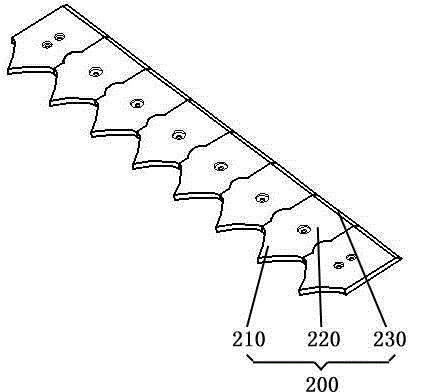

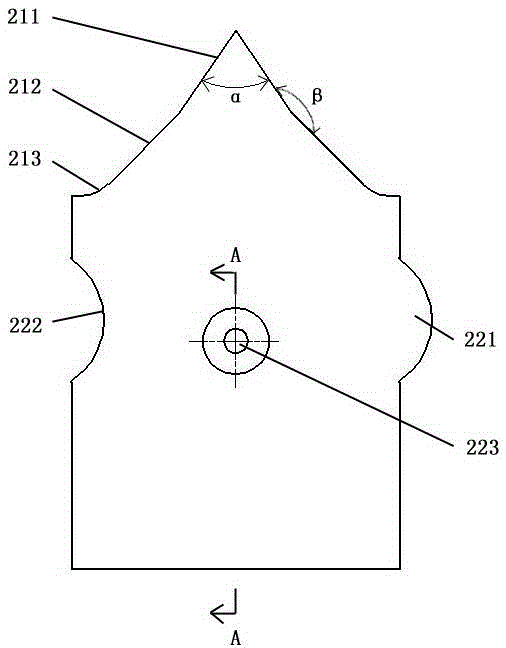

[0032] figure 1 The loader bucket shown includes a bucket body 100 and a plurality of bucket teeth installed at the front end of the bucket body 100, and these bucket teeth are a plurality of movable blades 200 spliced side by side, see figure 2 The movable blade 200 is a flat plate, and each movable blade 200 is installed and fixed under the main cutting plate 110 of the bucket body 100 by means of bolt connection. After the installation is completed, the working part of the movable blade 200 protrudes from the main Cutting the outside edge of plate 110; as image 3 The movable knife plate 200 shown has a connecting part 220 and two working parts respectively arranged at the two ends of the connecting part 220. The two working parts are the tine part 210 and the flat tooth part 230 connected with the connecting part 220 respectively. The free end of the tooth part 210 is a pointed tooth tip, which extends obliquely from the tooth tip to the two sides of the connecting par...

Embodiment 2

[0035] Such as Figure 7 and Figure 8 As shown, the structural features of the bucket body 400, the main cutting plate 410 and the movable knife plate 500 of this embodiment are the same as those of the first embodiment, the difference is that the two outermost movable knife plates 500 are turned backward by 180° during installation. °, the installation positions are exchanged with each other, and the rest of the movable blades 500 only need to move backward 180°, that is, press each movable blade 500 Figure 8 The splicing method is installed and fixed under the main cutting plate 410 of the bucket body 400, so that the flat teeth 510 of each movable knife plate 500 protrude from the outside of the main cutting plate 410. After the installation is completed, it can be used for shoveling and crushing treatment. The cold steel slag, which is a loose material with low density, is closely connected with the flat teeth 510 of the adjacent movable blades 500 during the shoveling ...

Embodiment 3

[0037] In this embodiment, the included angle α between the two sections of the first beveled edge of the tine portion of the movable blade is 75°, and the included angle β between the first beveled edge and the second beveled edge on the same side is 150°. All the other features are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com