Wood floor with damp-roof function and silencing function for floor heating

A wooden floor and functional technology, applied in the direction of floors, buildings, building structures, etc., can solve the problems of troublesome laying, troublesome laying process, no mute function, etc., and achieve the goal of reducing laying cost, simplifying the laying process, and good moisture-proof effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

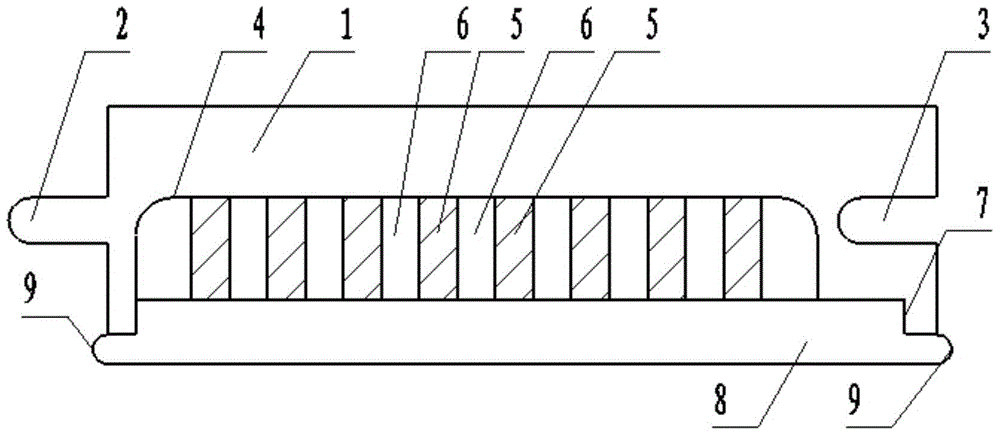

[0011] Example. Wooden floor for floor heating with moisture-proof and mute function, composed of figure 1 As shown, including the wooden floor 1, the middle position on the left side of the wooden floor 1 is provided with a tenon 2, and the middle position on the right side of the wooden floor 1 is provided with a tenon 3; the wooden floor 1 is provided with a cavity 4, and the angle between the cavity 4 All are provided with rounded corners; multiple wooden sound-absorbing panels 5 are vertically connected in the cavity 4, and gaps 6 are provided between the wooden sound-absorbing panels 5; the bottom of the wooden floor 1 is provided with a stop 7, and the bottom of the wooden floor 1 passes through the stop 7 The rubber layer 8 is glued and connected; the upper surface of the rubber layer 8 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com