Chain type cutter assembly structure

A cutter and assembly technology, applied in the direction of shaft lining, tunnel lining, underground chamber, etc., can solve the problems of inconvenience, extension of construction period, soil stress release, etc., to facilitate installation and disassembly, improve grouting efficiency, good looking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

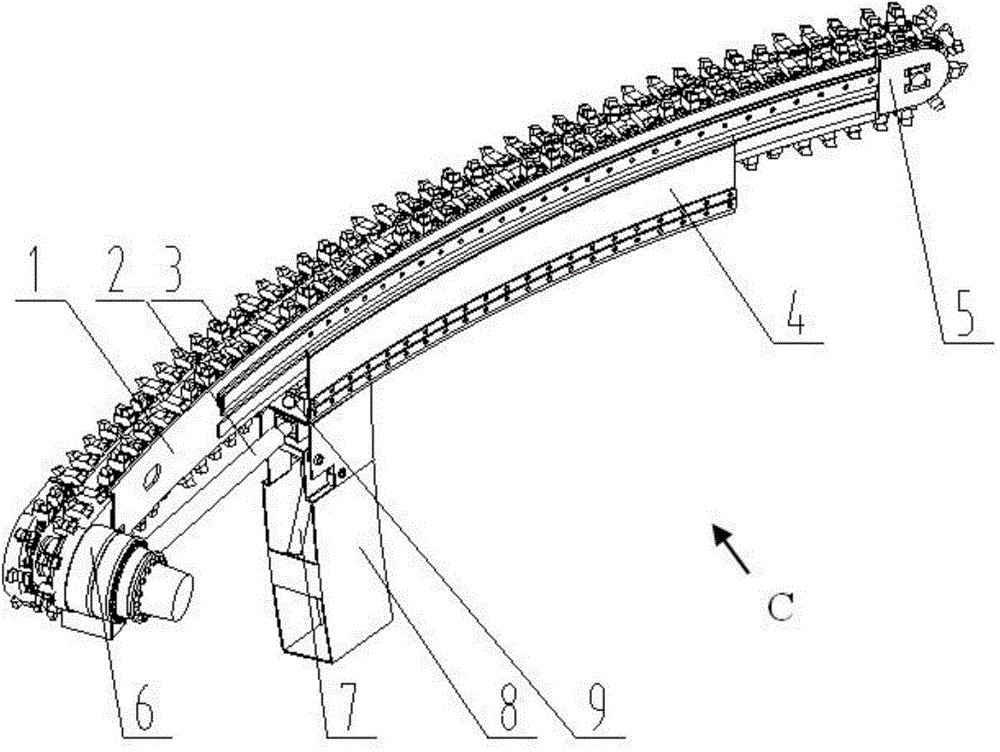

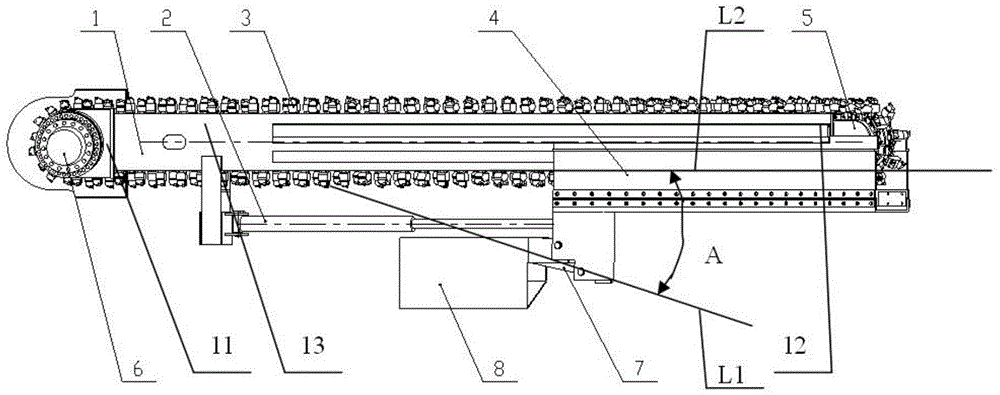

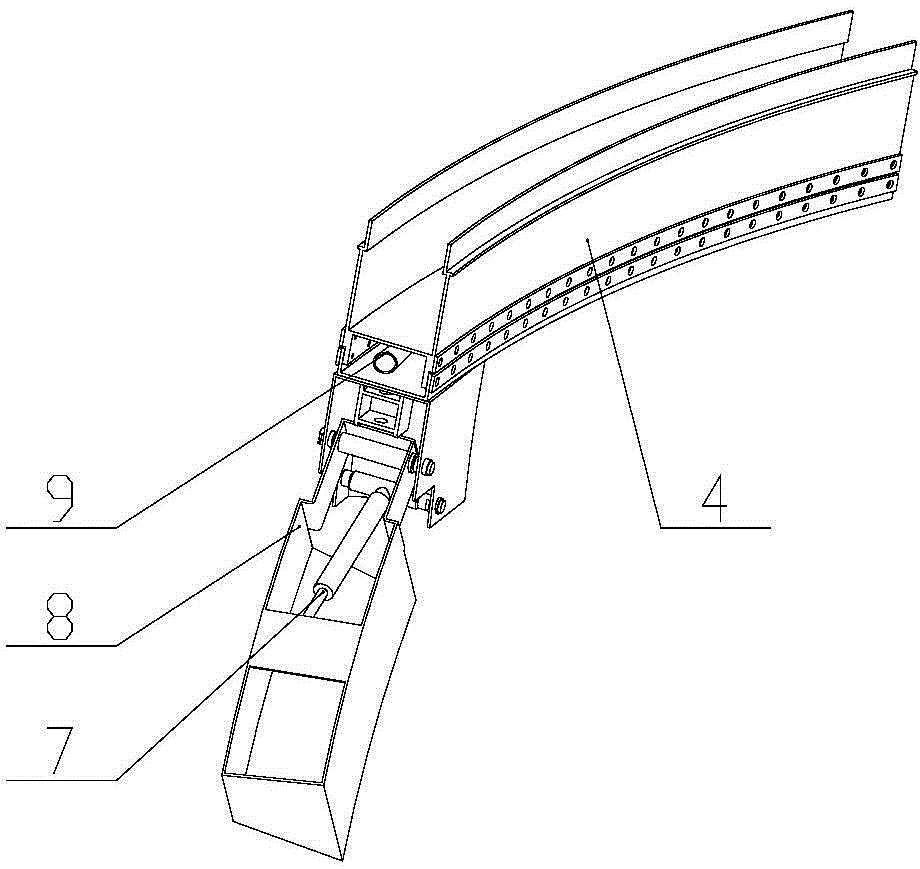

[0035] A chain cutter assembly mechanism, see figure 1 , figure 2 as well as image 3 , including cutter body 1, sliding form telescopic cylinder 2, chain cutter 3, sliding template 4, driven device 5, driving device 6, vertical mold opening and closing cylinder 7, vertical template 8 and grouting pipe 9, wherein cutter body 1 , chain knife 3, driven device 5 and driving device 6 are combined to form a grooving mechanism, sliding form telescopic cylinder 2, sliding formwork 4, vertical mold opening and closing cylinder 7, vertical formwork 8 and grouting pipe 9 are combined to form a concrete synchronous pouring mechanism , The concrete synchronous pouring mechanism is fixed on the grooving mechanism, which acts synchronously with the grooving mechanism, and the overall structure is simplified.

[0036] The cutter body 1 includes a front end 11, an end 12 and a side surface 13, and the driving device 6 and the driven device 5 are movably arranged on the end 12 and the front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com