Water-cooled commercial stove energy-saving hearth

A water-cooled furnace technology, applied in the furnace field, can solve the problems of undurable, safe and hidden dangers in metal casting furnaces, and achieve the effects of preventing the furnace from bursting and scrapping, improving efficiency, and solving potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited to the following embodiments.

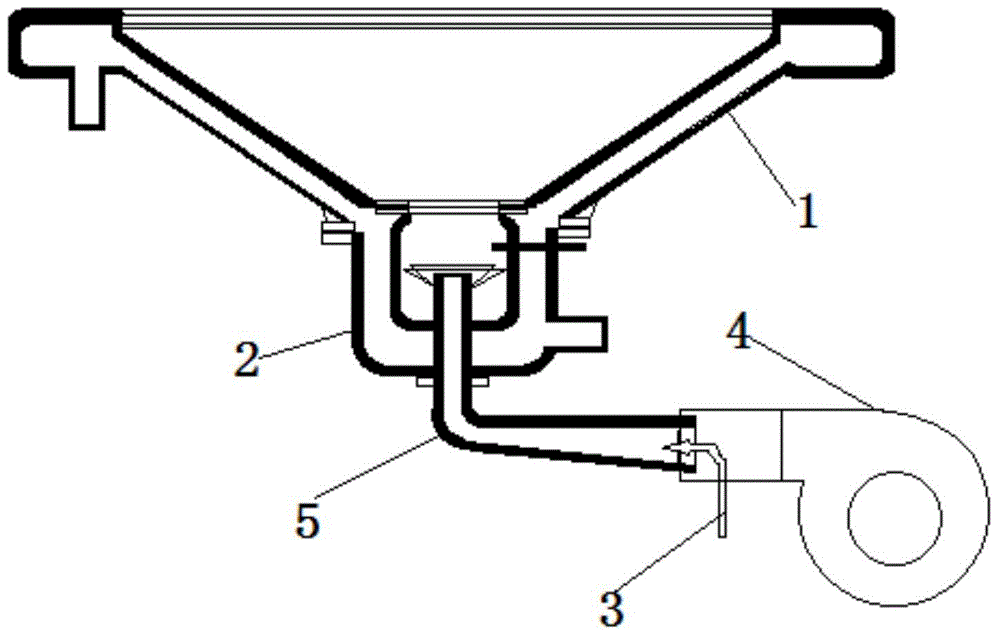

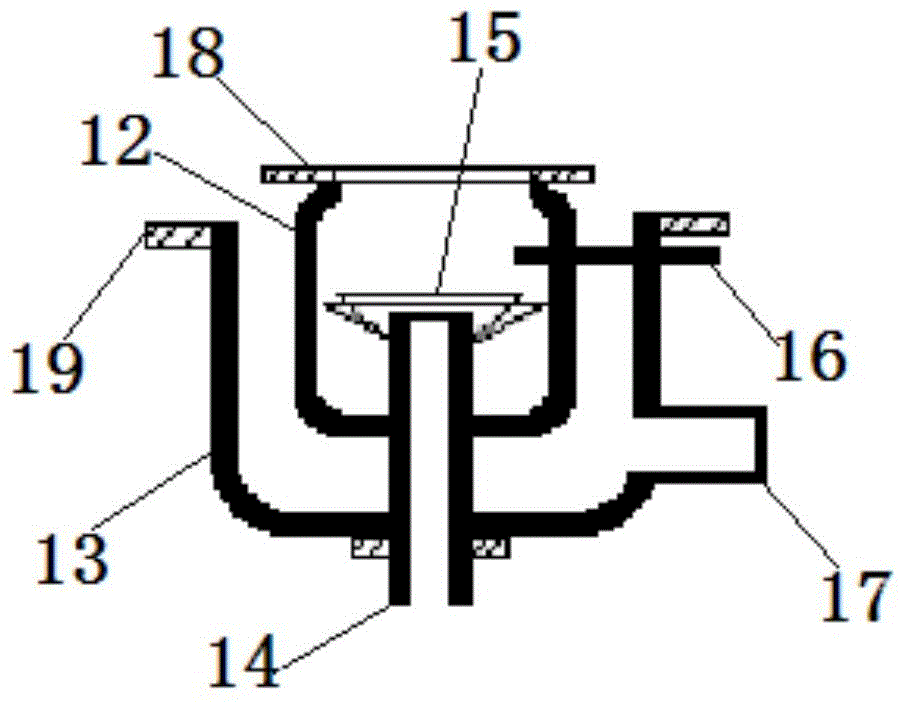

[0017] The overall structure of the energy-saving hearth of the water-cooled commercial frying stove provided by the invention is as follows: figure 1 and Figure 4 As shown, it at least includes a furnace body 1 , a furnace head 2 , a gas nozzle 3 , a blower 4 and a premixed gas pipe 5 . The burner 2 is installed below the furnace body 1, the top of the premixed gas pipe 5 is connected with the burner 2, the bottom of the premixed gas pipe 5 is connected with the gas nozzle 3 and the blower 4, and the blower is provided with an air inlet pipe.

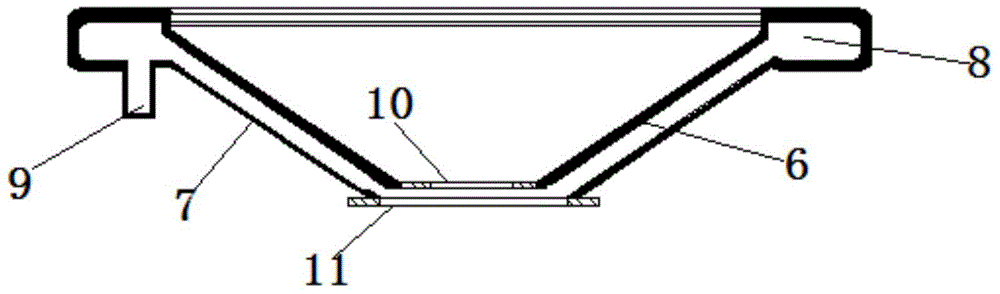

[0018] The structure of the furnace body is as figure 2 As shown, the furnace body is in an inverted conical shape as a whole, at least including the inner wall 6 of the furnace, the outer wall 7 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com