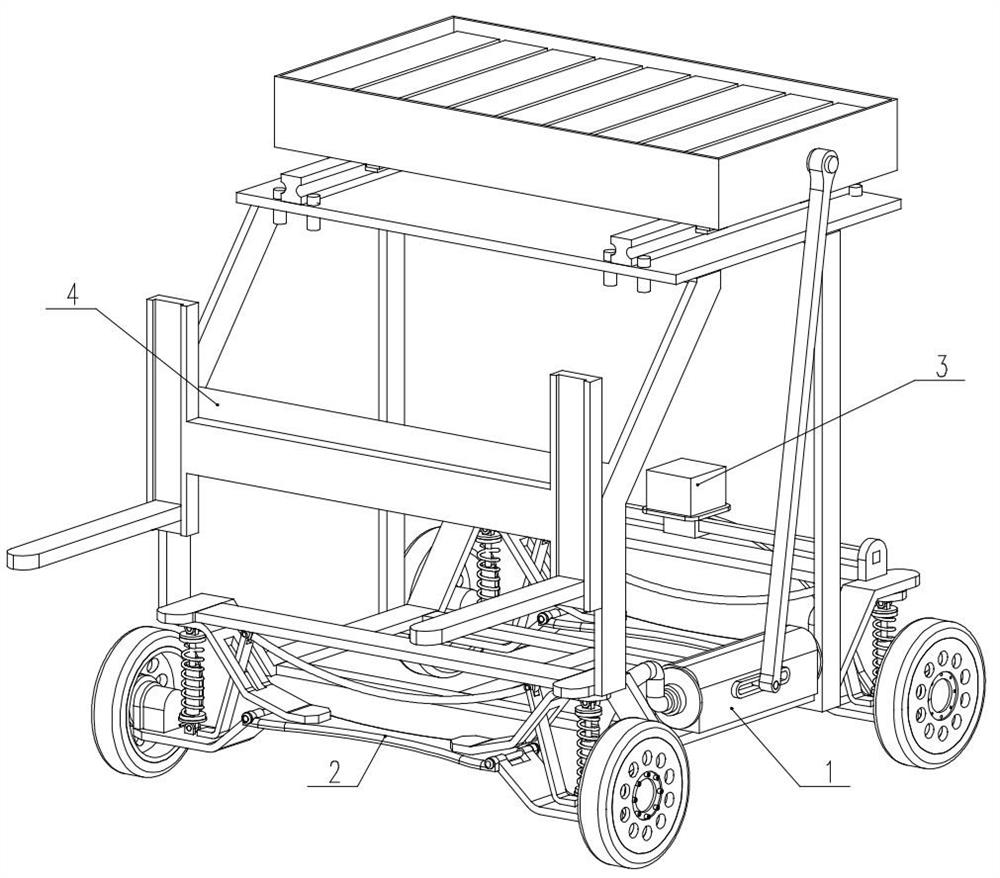

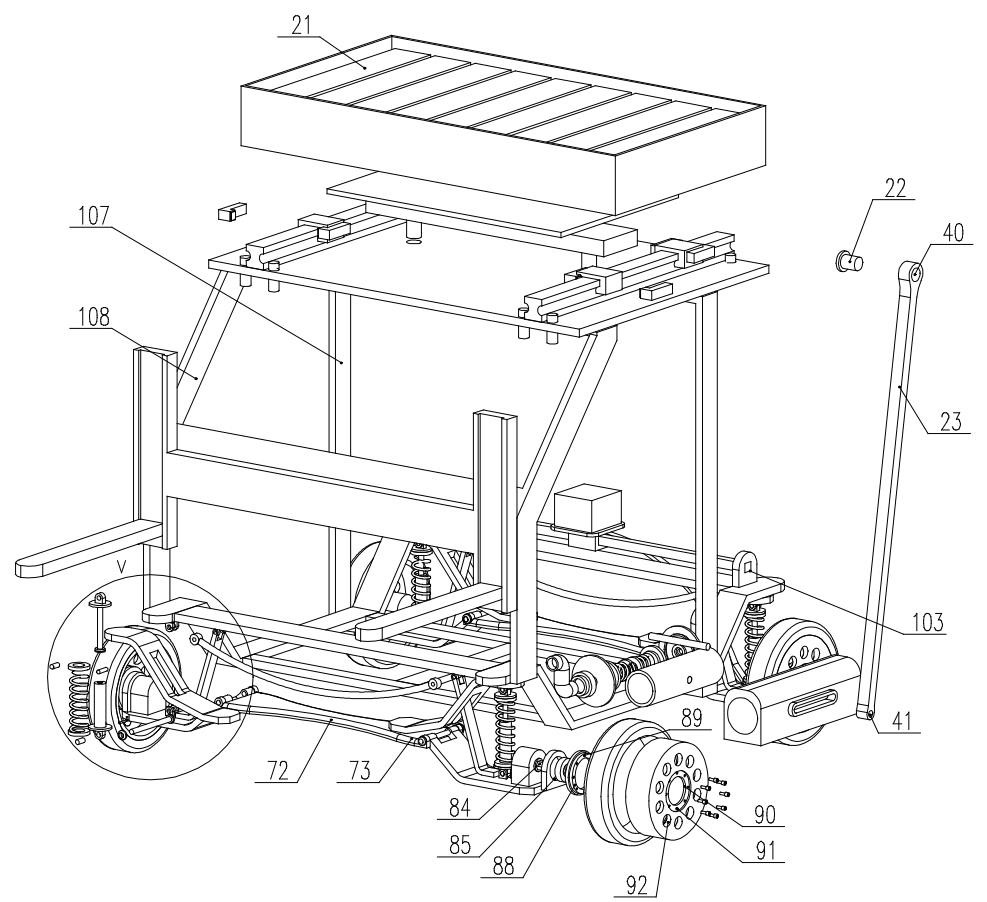

[0009] In view of the above situation, in order to overcome the defects of the prior art, the present invention provides a counterweight forklift with automatic counterweight and its use method. The present invention creatively proposes the principle of self-adaptive counterweight adjustment. The

hydraulic cylinder in the middle senses the compression amount of the main

shock absorber spring and expands and contracts with the spring. The amount of medium flowing out of the front and rear hydraulic cylinders is different, pushing the counterweight box to slide forward and backward, realizing the dynamic adjustment of the counterweight box, thereby adaptively correcting the center of gravity of the forklift Position, in the absence of any sensor and

electronic control system, the automatic correction of the center of gravity of the forklift can be realized only by simple mechanical structure and

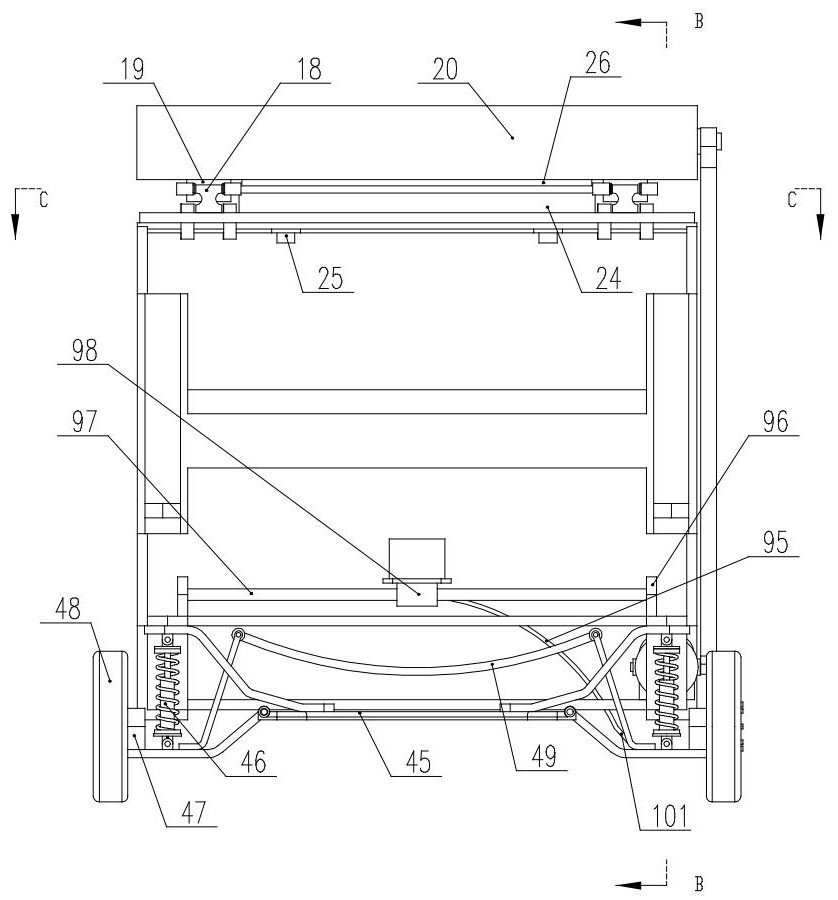

hydraulic structure, and the front and rear springs caused by the forward movement of the center of gravity can be compensated by moving the counterweight box The phenomenon of uneven gravity distribution and large difference in compression can not only solve the problem that the forklift is easy to lean forward when forklifting heavy objects and easy to lean backward under no-load state; it can also move the forklift under no-load and full-load The gravity is relatively evenly distributed on each spring, which solves the problem of premature

fatigue damage of the spring of the rear suspension caused by too long no-

load time or premature

fatigue damage of the spring of the rear suspension caused by too long full-

load time; similarly, forklifts Not only will the position of the center of gravity shift forward and backward due to the loading of goods, but also the center of gravity of the goods will not be on the left and right centerlines of the forklift due to unavoidable operating errors. At this time, the forklift will also have uneven distribution of gravity in the left and right directions. , the present invention also proposes a self-adaptive lateral compensation structure with a simple structure, which adjusts the left and right sliding of the counterweight through the relative rotation of the

independent suspension platform and the elastic damping plate of the wing suspension, and then controls the

lateral movement of the center of gravity Make corrections to reduce the adverse effects caused by the uneven distribution of gravity on the left and right of the forklift; the general forklift uses the steering gear with the front wheel rotation angle to control the direction of travel, but this conventional steering method has a large

turning radius, while the forklift The

working environment is often a narrow warehouse. In order to solve this problem, the present invention creatively proposes a four-wheel independent drive system without a steering gear, which controls the forklift to move forward and backward by independently controlling the rotation direction of the inner wheel and the outer wheel. , turning, or U-turn on the spot, which solves the problem of large

turning radius of forklifts; although this steering method is simple in structure, comprehensive in function and strong in adaptability, the wear rate of tires is faster than that of ordinary steering methods. In order to ensure durability, The present invention uses

solid tires instead of traditional pneumatic tires to solve the problem of tire durability; as we all know,

solid tires have high

hardness and are not as comfortable as pneumatic tires. A wing-type balanced semi-independent

shock absorber is developed. Four sets of relatively

independent suspension systems are used to ensure the passability and comfort when overcoming obstacles. The two sets of suspensions at the same end are connected together by a high-

toughness arc-shaped elastic balance device. , with the torsionable central narrow bridge in the middle of the wing-type suspension elastic damping plate, the overall

toughness of the

chassis is improved on the premise of ensuring independence, and the comfort and stability of the forklift are further improved, thus solving the long-term problem The unsolved problem of reducing the

turning radius of the forklift while ensuring durability and comfort; the self-adaptive adjustment process of the counterweight box only occurs in the stage of lifting and lowering the goods. During the operation phase, the

electromagnetic lock of the counterweight box can be used The device fixes the position of the counterweight box, which solves the problem that it is easy to slide repeatedly with the counterweight box when the center of gravity moves greatly due to

inertia during operation; when driving on flat roads such as self-leveling ground in the workshop, it can lock the electromagnetic medium The method of controlling the valve improves the rigidity of the chassis, reduces the degree of chassis shaking, and reduces the possibility of

rollover, forward tilt or backward tilt; the electromagnetic counterweight box locking device can pass the

static friction between the flat

electromagnet and the

metal Prevent the counterweight box from sliding. When lifting and lowering the goods, that is, when the counterweight box slides, the thermal locking device at the end prevents the counterweight box from sliding past the limit position, and solves the problem that the slider may fall off; effectively solves the problem that the current market When the forklift is unloaded, the gravity is concentrated on the rear wheel, and when it is fully loaded, the gravity is concentrated on the front wheel. The problem that a certain spring is prone to accelerated fatigue and aging is also solved. Problems with too large turning

radius and inconvenient operation

Login to View More

Login to View More  Login to View More

Login to View More