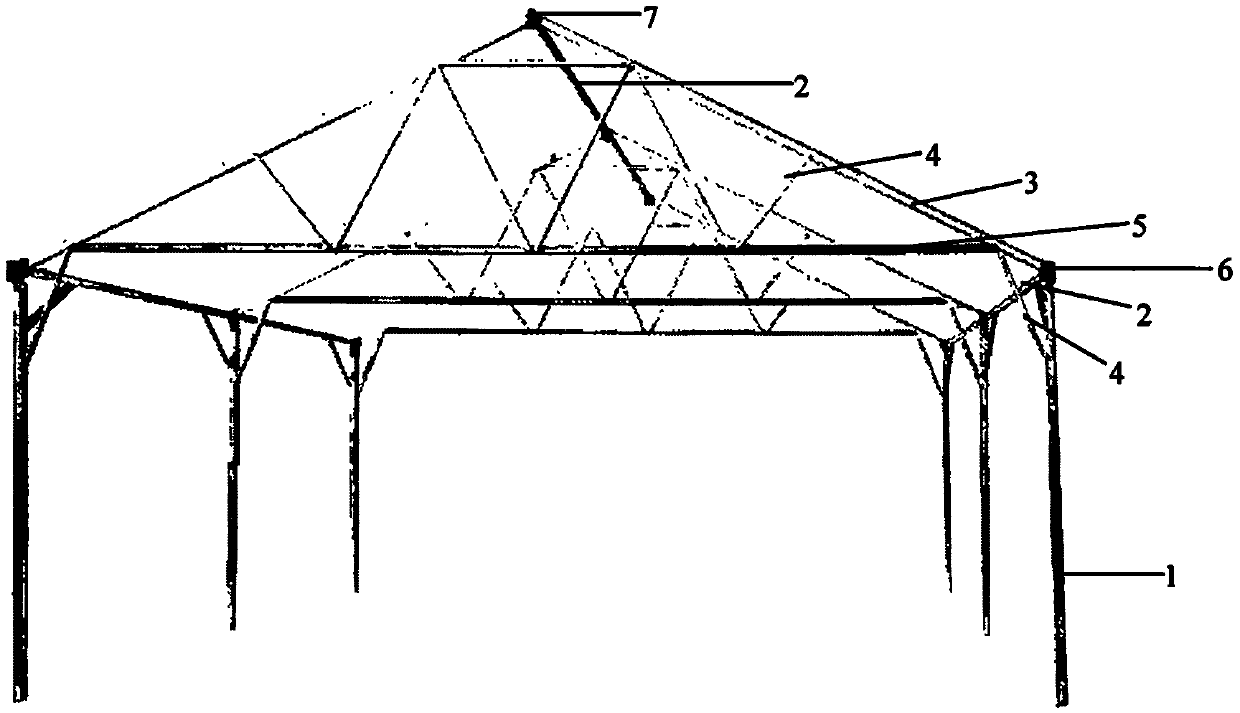

Ridge-shaped combined building structure

A technology of building structure and ridge shape, which is applied in the direction of buildings, building types, truss structures, etc., to achieve the effects of increased stress strength, increased flexibility, and improved manufacturing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

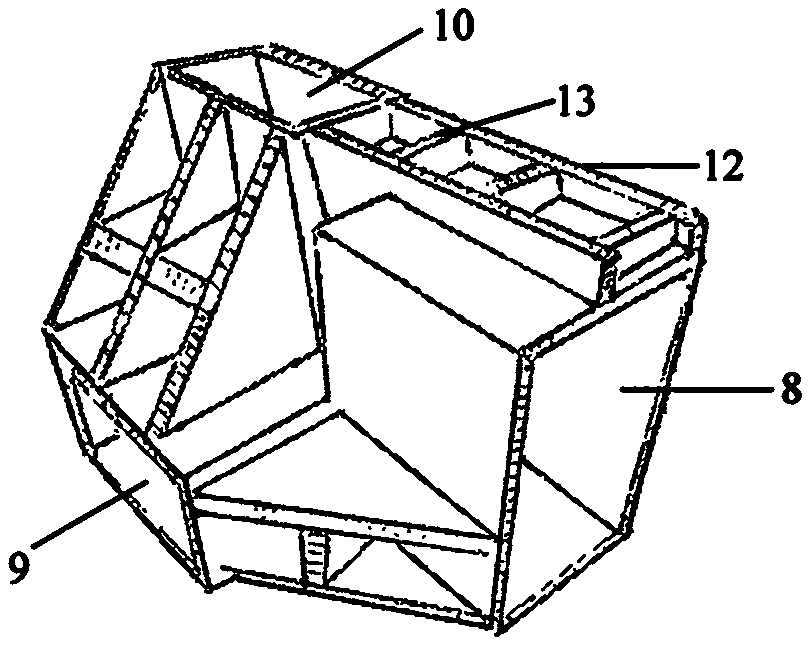

[0015] 1. Plastic assembly mold processing and injection molding production process and technology are mature. The raw material is polycarbonate (PC) or PC+ABS plastic alloy with good toughness, and the production process is abbreviated.

[0016] 2. Square tube specifications and assembly jack specifications: General conditions: beams and inclined beams use 4 cm * 2 cm square tubes; columns use 4 cm * 2 cm; 4 cm * 4 cm; 5 cm * 3 cm; 6 cm*4cm square tube.

[0017] 3. Column height: generally 1.5 meters to 3 meters.

[0018] 4. Width (width): Generally, it can be made into 2 to 7.5 meters. Multiple triangular pulls are used for large spans to form a herringbone frame with multiple triangles. At the same time, the specifications of the column square tubes should be large, such as 5 cm * 3 cm square tubes. When the assembly angle is constant, the length of the inclined beam determines the span. Take the angle of 23.5 degrees in the horizontal plane of the inclined beam as an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com