Printing quality visual detection method

A visual inspection and printing quality technology, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problems of reduced efficiency of inspection equipment, impossible time saving, and huge waste of inspection system resources, etc., to achieve complete separation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for visual inspection of printing quality, the method comprising the following content:

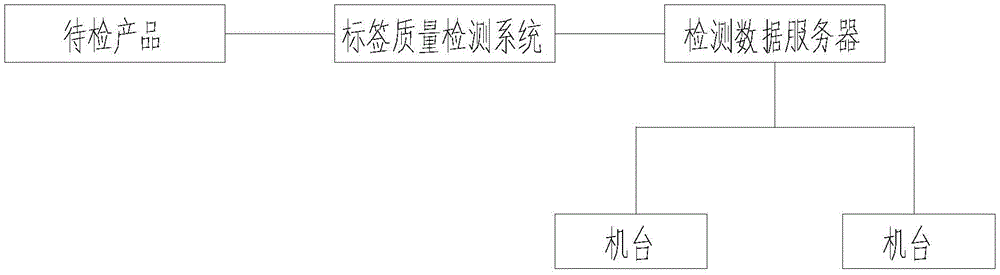

[0022] Label quality inspection system: It can be installed on printing machines, rewinding inspection machines and slitting machines. The label quality inspection system will inspect the product labels that need to be inspected, and upload the product location, image and product label defect information to the inspection data server;

[0023] Detection data server: responsible for receiving, storing and sending defect information of product labels;

[0024] Machine table: It is used to store products with defective labels, and the machine table can download the defect information corresponding to the product label from the inspection data server. Workers can select the defective labels to be removed on the machine table, and complete the final label removal and the labeling process;

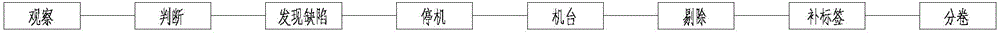

[0025] Operation mode: The label quality inspection system detects the labels of the p...

Embodiment 2

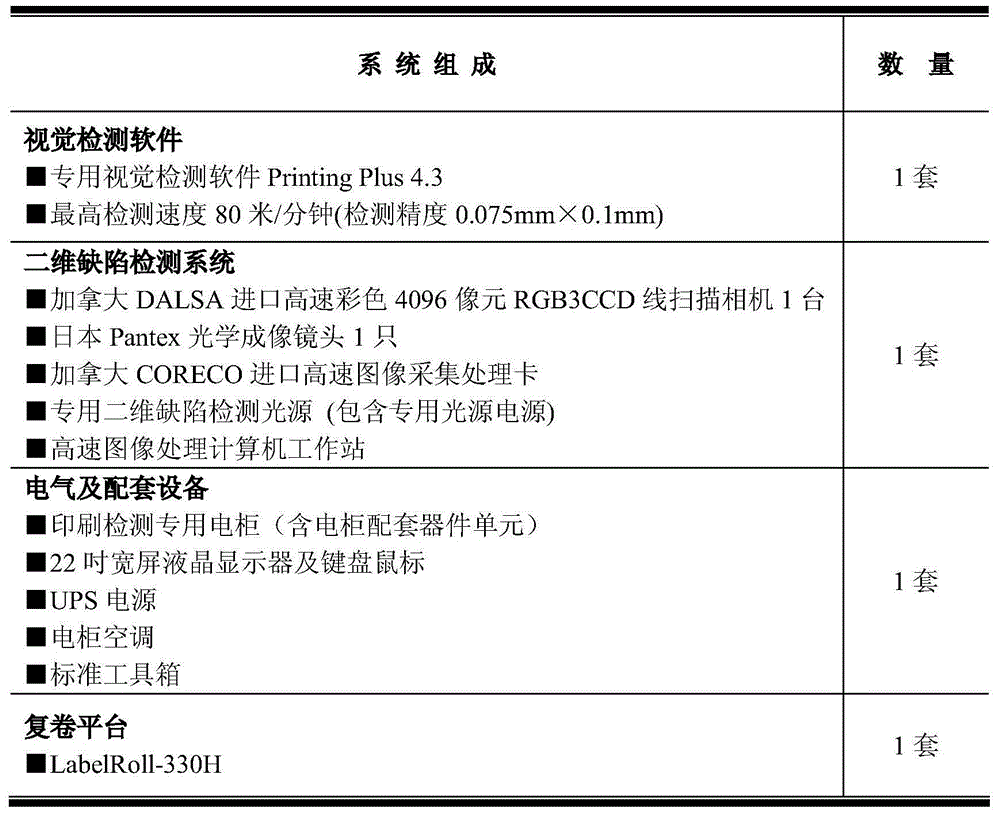

[0039] The parameter index in the actual work of the label quality detection system can be set as:

[0040] Width: 200mm

[0041] Light source: symmetrical light source + laser light source

[0042] Rewinding platform: adopt CR9035B rewinding platform

[0043] Camera: PC30-04K80*2 camera

[0044] Detection speed: 50 m / min

[0045] Resolution:

[0046] Horizontal resolution: 0.05mm

[0047] Vertical resolution: 0.05mm

[0048] Detection object: high-end electronic label. Other parts are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal resolution | aaaaa | aaaaa |

| Vertical resolution | aaaaa | aaaaa |

| Horizontal resolution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com