Humidity-controllable static gas-sensitive test device and method

A test device, static technology, applied in the direction of measuring device, humidity control, non-electric variable control, etc., can solve the problems of poor stability, poor humidity controllability, difficult to build, etc., to achieve low cost, simple device, simple and stable Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

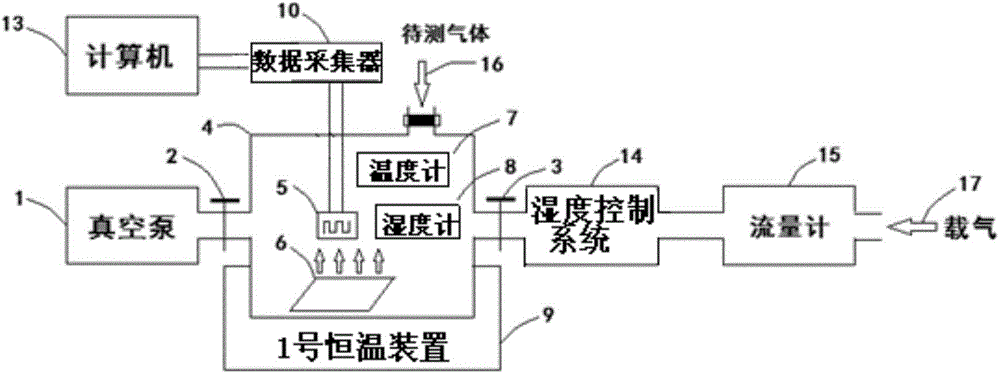

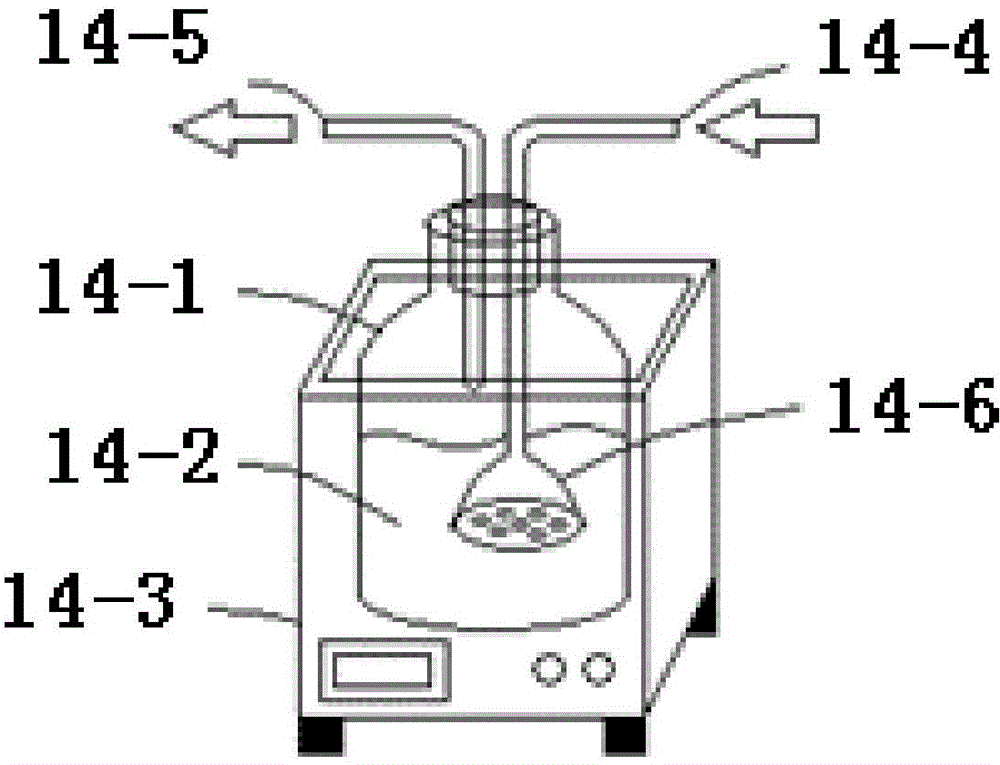

[0035] Specific implementation mode one: see figure 1 Describe this embodiment mode, a kind of controllable humidity static gas sensitive testing device described in this embodiment mode, it comprises gas test system, humidity control system 14 and data acquisition system,

[0036] The gas testing system includes a gas chamber 4, a gas sensor 5, a fan 6, a thermometer 7, a hygrometer 8 and No. 1 thermostatic device 9;

[0037] The data acquisition system includes a data collector 10 and a computer 13;

[0038] The air inlet of the humidity control system 14 is used to pass into the carrier gas 17, the air outlet of the humidity control system 14 communicates with the No. 1 air inlet of the air chamber 4 through the No. 1 gas valve 3, and the air chamber 4 is provided with Gas sensor 5, fan 6, thermometer 7 and hygrometer 8; fan 6 is used to mix the gas to be measured in the gas chamber 4,

[0039] The signal output end of gas sensor 5 is connected with the data signal input ...

specific Embodiment approach 2

[0043] Embodiment 2: The difference between this embodiment and the humidity-controllable static gas-sensing test device described in Embodiment 1 is that it also includes a vacuum pump 1, and the vacuum pump 1 communicates with the gas chamber 4 through the No. 2 gas valve 2 .

specific Embodiment approach 3

[0044] Specific embodiment three: the difference between this embodiment and the static gas-sensing test device with controllable humidity described in specific embodiment one or two is that it also includes a flow meter 15, and the flow meter 15 is used to measure the load Gas 17 flow.

[0045] In this embodiment, the flow meter 15 and the vacuum pump 1 constitute a gas flow system for adjusting the flow and velocity of the carrier gas 17 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com