Intelligent inspection system and intelligent inspection method

A technology of intelligent inspection and inspection tasks, applied in transmission systems, inspection time patrols, instruments, etc., can solve problems such as false inspections, reduced GPS positioning accuracy, quantitative assessment of inspection personnel, etc., to improve management efficiency and improve Flexibility, the effect of achieving traceability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

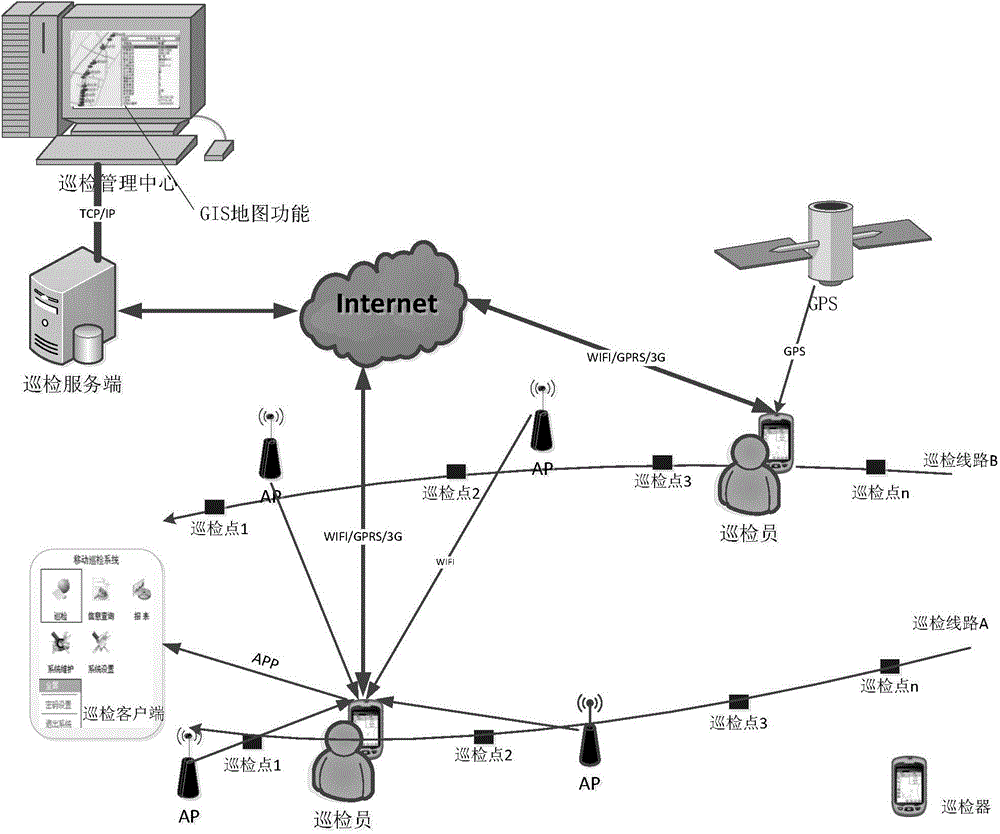

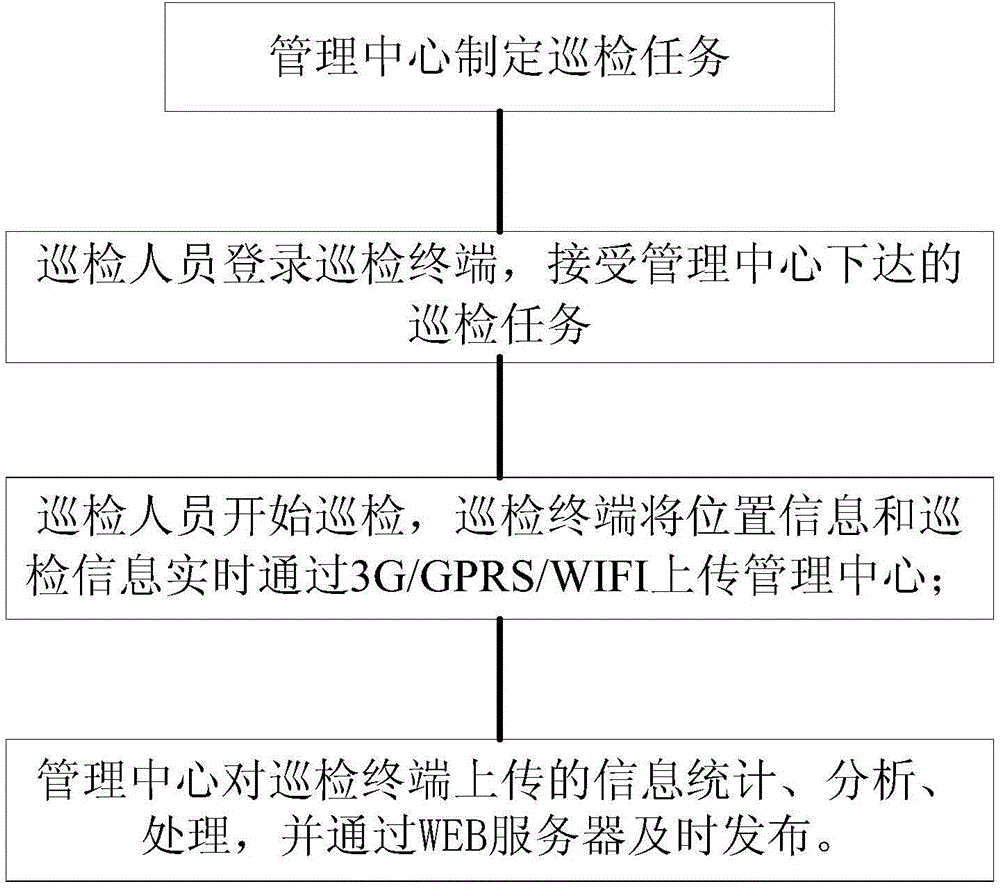

[0066] like figure 1 As shown, the intelligent inspection system consists of a management center, inspection terminals and other necessary network equipment. The inspection terminal and management center are connected through GPRS / 3G / WIFI wireless network; the management center includes data server, WEB server and management terminal, which is mainly responsible for the management and information release of the service system; the inspection terminal is composed of GPS inspection terminal, responsible for collecting The location information of the inspectors, acceptance of inspection tasks, reporting of inspection results, etc.

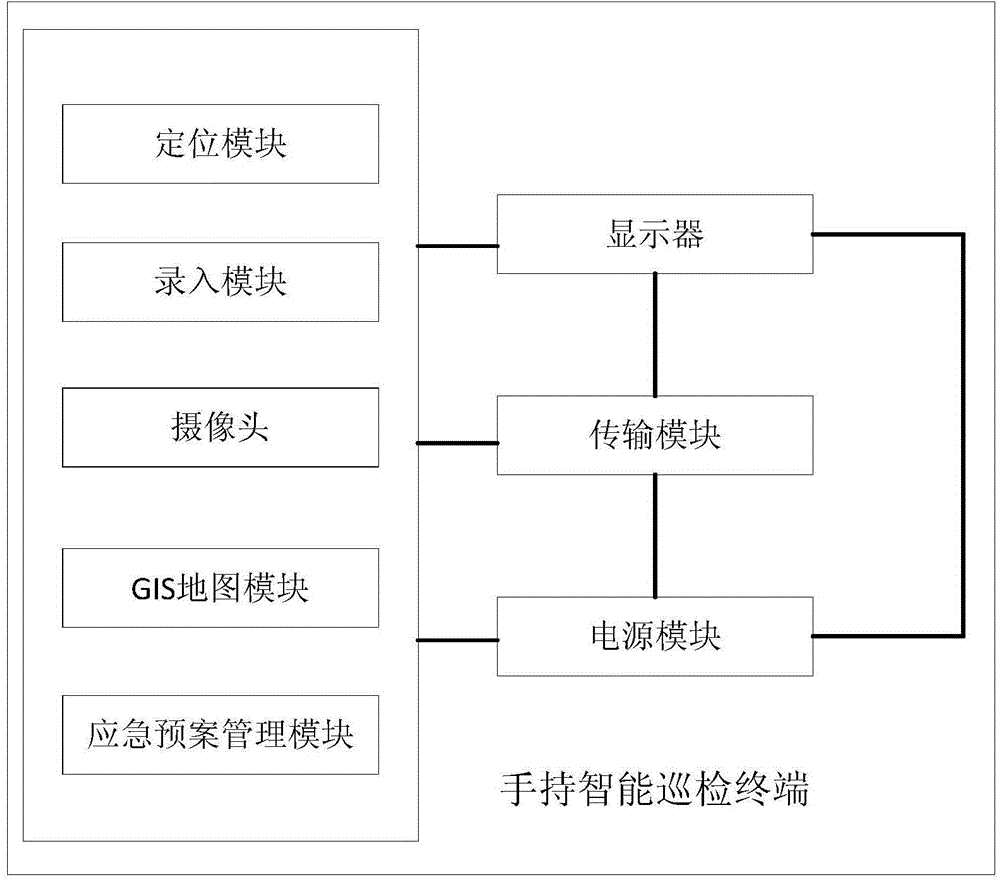

[0067] The intelligent inspection system of this embodiment includes an intelligent inspection terminal, an inspection server, and an inspection management center. The intelligent inspection terminal adopts an M / S structure and is used to collect location information of inspection personnel and accept inspection tasks. , report inspection results and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com