Fluorescent read-out rewritable phase change optical disc

A phase change and fluorescence technology, applied in optical recording/reproduction, data recording, instrumentation, etc., to achieve strong data retention, optimized performance, and high cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

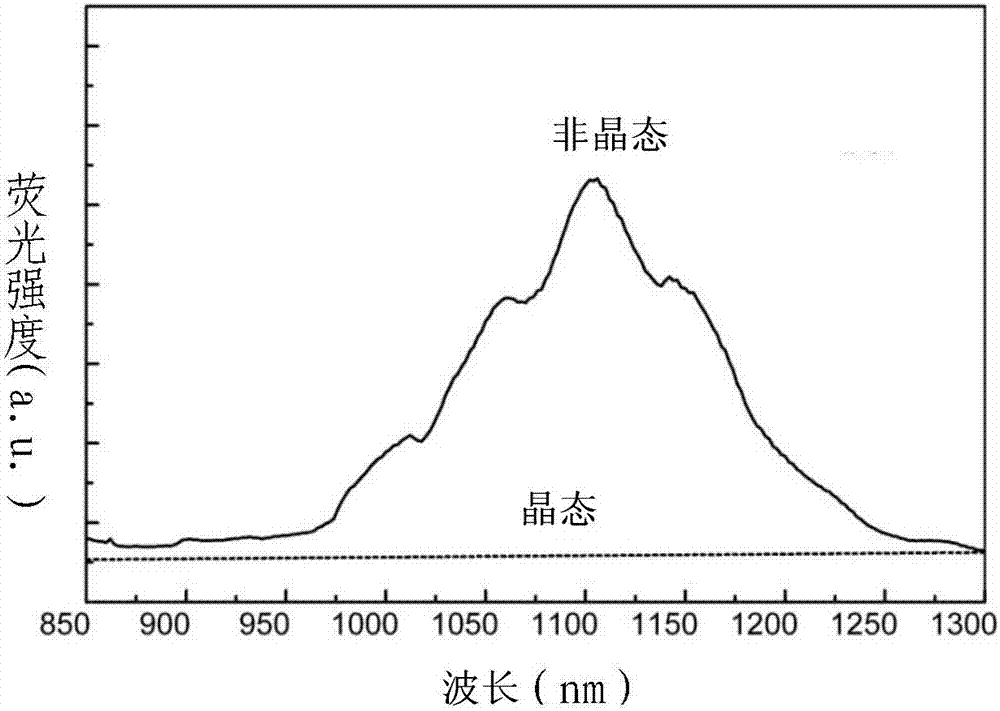

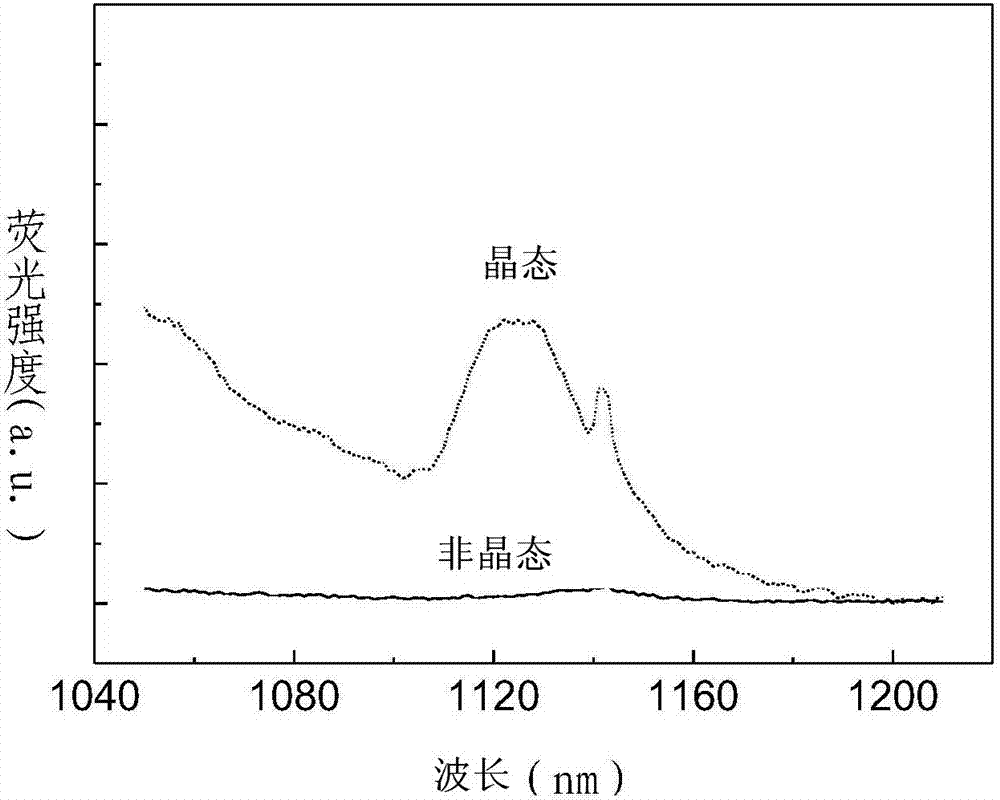

Problems solved by technology

Method used

Image

Examples

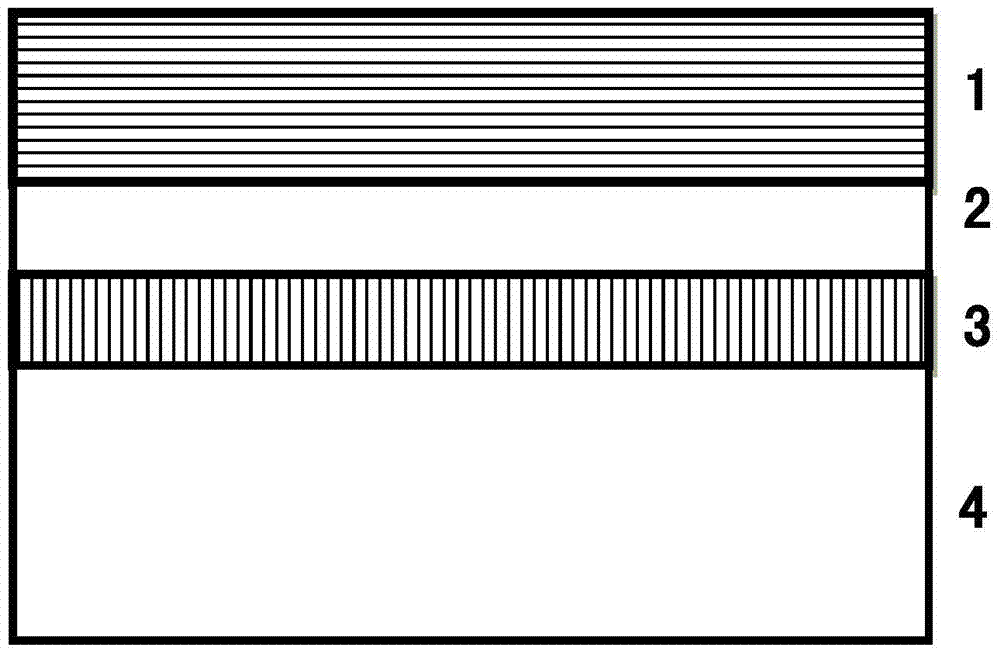

Embodiment 1

[0024] A lower protective layer, a Bi ion-doped fluorescent phase-change recording layer and an upper protective layer are sequentially prepared on a phase-change optical disc substrate by magnetron sputtering. The upper and lower protective layers use ZnS-SiO 2 The target is sputtered and the background vacuum is 3×10 -4 The pressure of Pa and Ar is 0.85Pa, the sputtering power is 140W, and the film thicknesses are 300nm and 100nm respectively. Using BiSb target and Sb 2 Te 3 Preparation of Bi Ion-doped Sb by Co-sputtering of -GeTe Alloy Target 2 Te 3 -GeTe fluorescent phase-change recording layer. The background vacuum is 3×10 -4 Pa, Ar pressure is 0.85Pa, the sputtering power of BiSb target is 2.1W, Sb 2 Te 3 - The sputtering power of the GeTe alloy target is 70W, and the film thickness is 100nm. Composition analysis shows that the atomic ratio of Bi ions in the film is 0.1 at.%.

Embodiment 2

[0026] A lower protective layer, a Bi ion-doped fluorescent phase-change recording layer and an upper protective layer are sequentially prepared on a phase-change optical disc substrate by magnetron sputtering. The upper and lower protective layers use ZnS-SiO 2 The target is sputtered and the background vacuum is 3×10 -4 The pressure of Pa and Ar is 0.85Pa, the sputtering power is 140W, and the film thicknesses are 300nm and 100nm respectively. Using BiSb target and Sb 2 Te 3 Preparation of Bi Ion-doped Sb by Co-sputtering of -GeTe Alloy Target 2 Te 3 -GeTe fluorescent phase change recording layer. The background vacuum is 3×10 -4 Pa, Ar pressure is 0.85Pa, the sputtering power of BiSb target is 3W, Sb 2 Te 3 - The sputtering power of the GeTe alloy target is 70W, and the film thickness is 100nm. Composition analysis shows that the atomic ratio of Bi ions in the film is 1.50 at.%.

Embodiment 3

[0028] A lower protective layer, a Bi ion-doped fluorescent phase-change recording layer and an upper protective layer are sequentially prepared on a phase-change optical disc substrate by magnetron sputtering. The upper and lower protective layers use ZnS-SiO 2 The target is sputtered and the background vacuum is 3×10 -4 The pressure of Pa and Ar is 0.85Pa, the sputtering power is 140W, and the film thicknesses are 300nm and 100nm respectively. Using BiSb target and Sb 2 Te 3 Preparation of Bi Ion-doped Sb by Co-sputtering of -GeTe Alloy Target 2 Te 3 -GeTe fluorescent phase-change recording layer. The background vacuum is 3×10 -4 Pa, Ar pressure is 0.85Pa, the sputtering power of BiSb target is 3.5W, Sb 2 Te 3 - The sputtering power of the GeTe alloy target is 70W, and the film thickness is 100nm. Composition analysis shows that the atomic ratio of Bi ions in the film is 2.0 at.%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com