Tackifier, preparation method thereof and silicone rubber composition

A tackifier and mixture technology, applied in adhesives, polymer adhesive additives, adhesive additives, etc., can solve problems such as difficult release of silica gel, no industrial application value, silica gel sticking to metal molds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

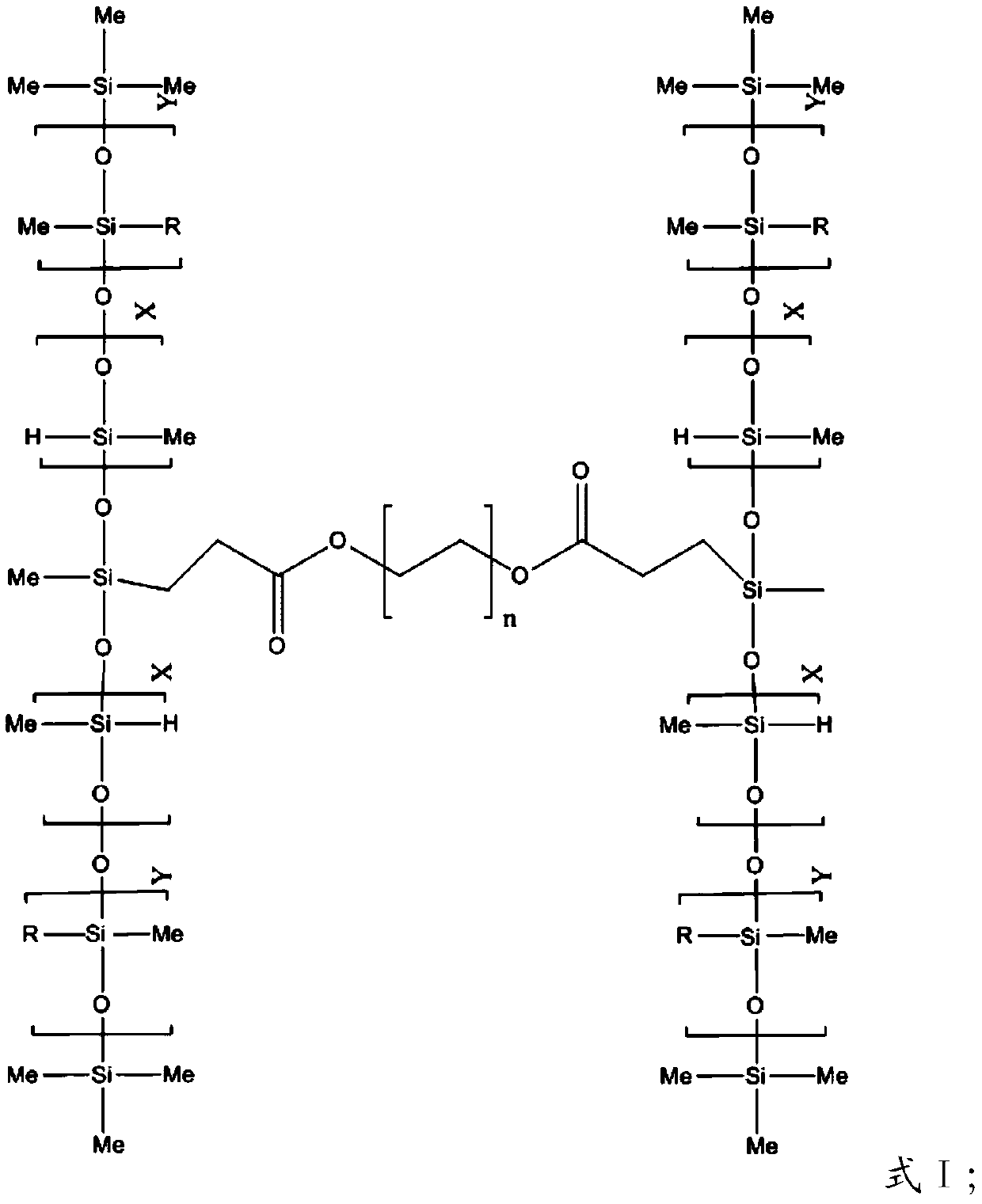

[0039] The present invention provides a kind of preparation method of tackifier described in above-mentioned technical scheme, comprises the following steps:

[0040] a) mixing a compound having a structure of formula II with toluene and a platinum catalyst to obtain a first mixture;

[0041] Mixing heptamethyltrisiloxane having a structure of formula III and toluene to obtain a second mixture;

[0042] 2≤n≤20;

[0043]

[0044] b) Adding the second mixture dropwise to the first mixture at 30-80°C for reaction to obtain an intermediate product having a structure of formula IV;

[0045]

[0046] c) The intermediate product having the structure of formula IV is mixed with a siloxane compound and an acidic substance, reacted at 30-70°C, and neutralized to obtain a tackifier; the siloxane compound is selected from tetramethylcyclotetrasilicon Oxane and / or Methylphenylcyclotetrasiloxane.

[0047] The method provided by the invention has mild conditions, is simple, has st...

Embodiment 1

[0072] A) Charge (110 g) toluene and the following compound into a 2000 mL four-necked flask equipped with a reflux condenser, a thermometer, a dropping funnel and a mechanical stirrer: (0.5 mol) 1,6-hexanediol diacrylic acid ester

[0073]

[0074] And the Castel Karstedt catalyst that accounts for 15ppm in the whole reaction system;

[0075] B) Heating to 70°C and adding dropwise within 3 hours. After the dropwise addition of (1mol) heptamethyltrisiloxane and (110g) toluene is completed, react at a constant temperature of 80°C for 3 hours to obtain an intermediate reaction product.

[0076]

[0077] Stir and cool the reaction product to 50°C, (0.3mol) 1,3,5,7-tetramethylcyclotetrasiloxane, (1g) 98% concentrated sulfuric acid, stir for 8h, cool to room temperature, add (5g) bicarbonate Sodium neutralization for 2 hours, filtration, 110°C, -0.95Mpa, removal of low molecular weight, to obtain the tackifier A with the structure of formula 101;

[0078]

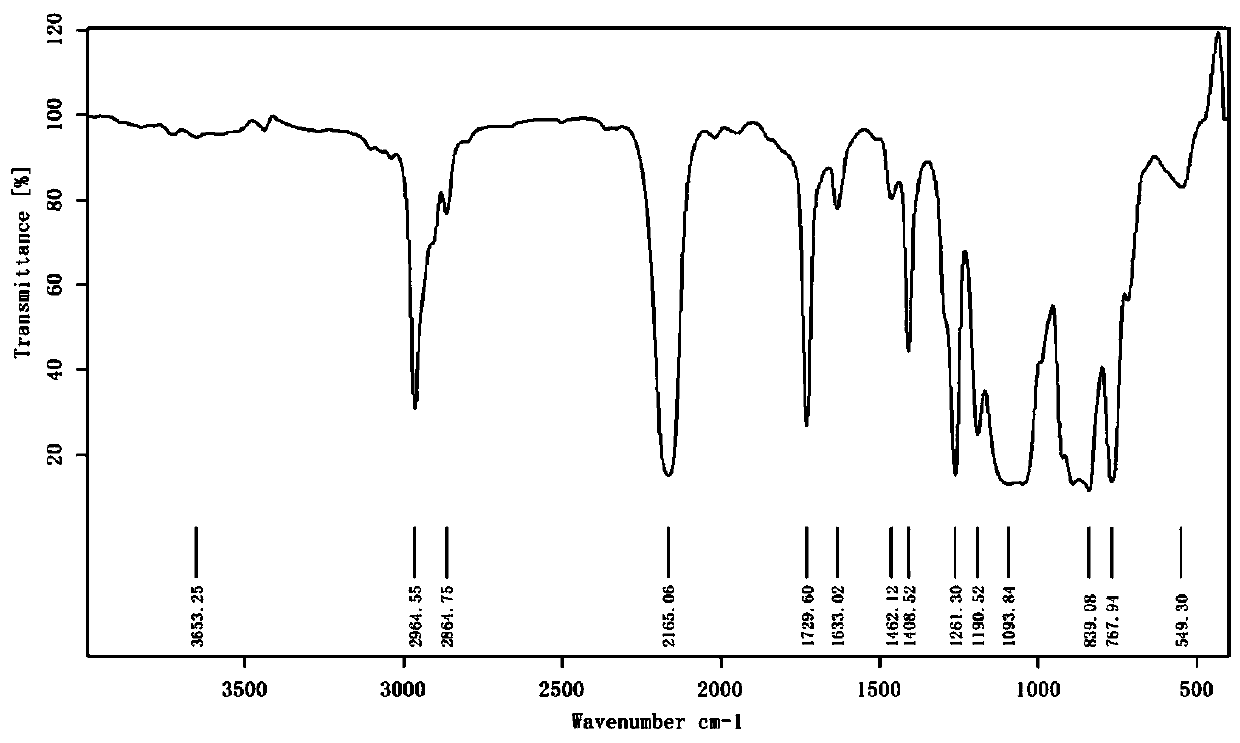

[0079] figur...

Embodiment 2

[0083] A) Charge (110 g) toluene and the following compound into a 2000 mL four-necked flask equipped with a reflux condenser, a thermometer, a dropping funnel and a mechanical stirrer: (0.5 mol) 1,9-hexanediol diacrylic acid ester

[0084]

[0085] And account for the Speier catalyst of 15ppm in the whole reaction system;

[0086] B) Heating to 70°C and adding dropwise within 3 hours. After the dropwise addition of (1mol) heptamethyltrisiloxane and (110g) toluene is completed, react at a constant temperature of 80°C for 3 hours to obtain an intermediate reaction product.

[0087]

[0088] Stir and cool the reaction product to 50°C, (0.3mol) 1,3,5,7-tetramethylcyclotetrasiloxane, (1g) 98% concentrated sulfuric acid and stir for 8h, cool to room temperature, add (5g) bicarbonate Sodium neutralization for 2 hours, filtration, 110°C, -0.95MPa, removal of low molecular weight, to obtain tackifier B with the structure of formula 102;

[0089]

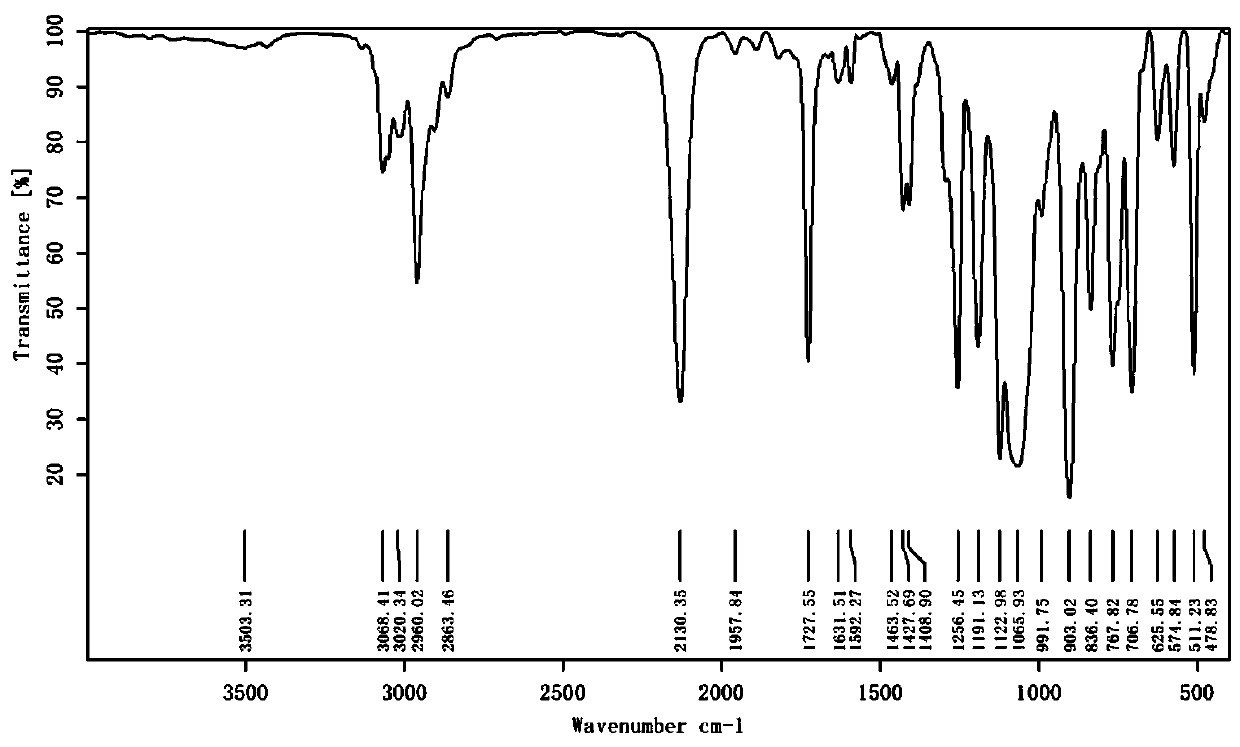

[0090] According to the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com