Electrode structure of LED chip with conductive substrate

A technology of LED chips and conductive substrates, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of reducing the service life of the chip, heat accumulation of the chip, shading of the light-emitting area of the chip, etc., to delay the decay of the chip, improve the life of the chip, The effect of reducing heat build-up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. The invention can be implemented at least on LED chips with non-conductive substrates, LED chips with conductive substrates and LED chips without substrates. Unless otherwise specified, within the knowledge of those skilled in the art, the electrode structure described below for a certain type of chip is universal for other types of chips.

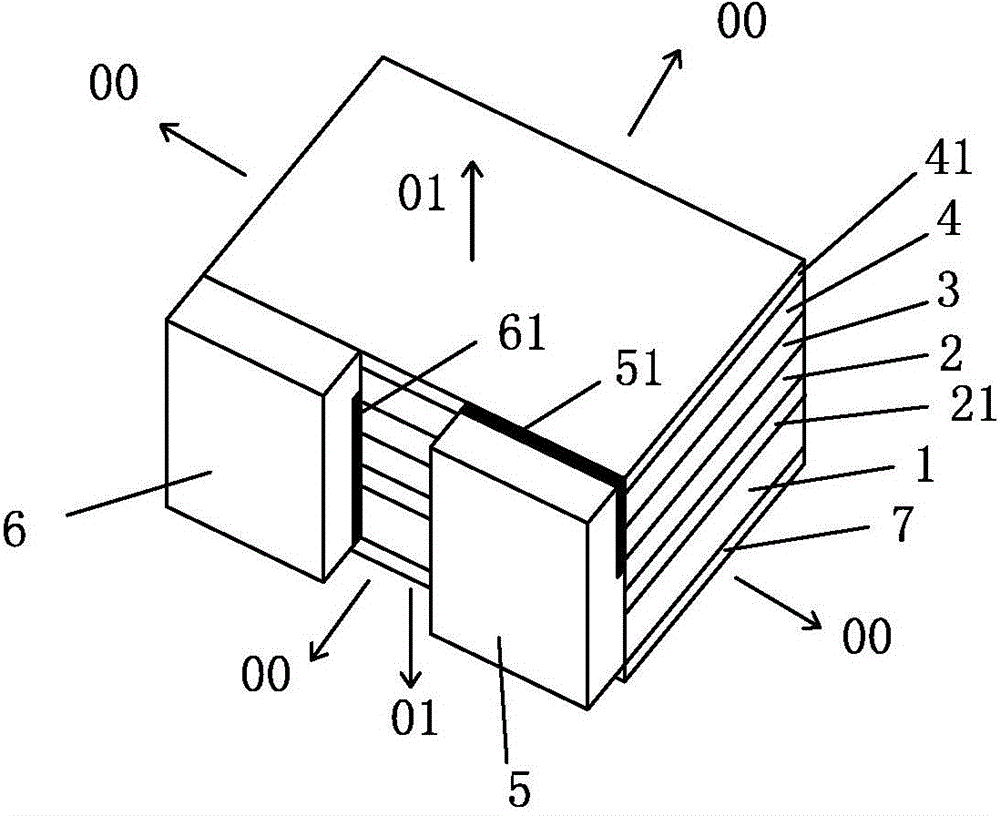

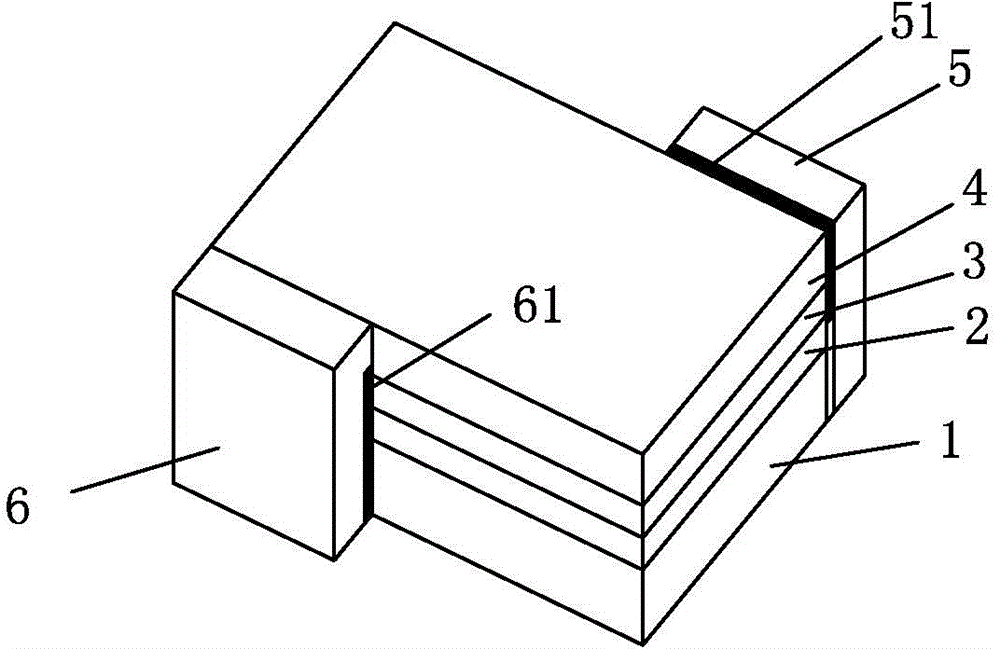

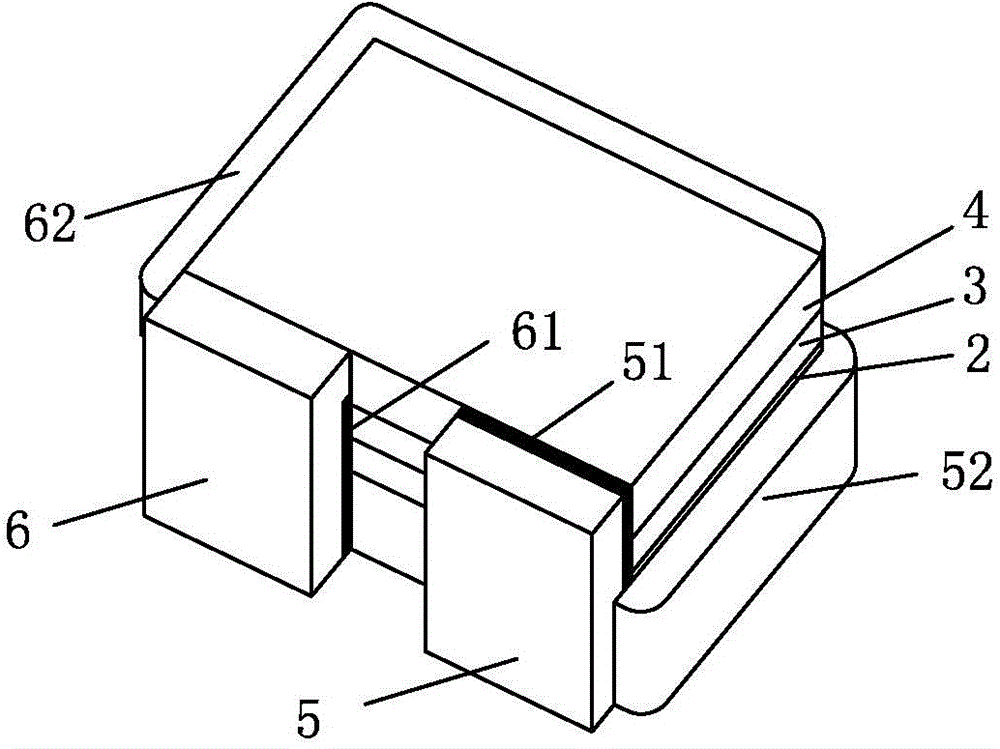

[0017] refer to figure 1 , taking a chip structure with a non-conductive dielectric sapphire as an example, there are substrate 1, N-type semiconductor layer 2, light-emitting layer 3 and P-type semiconductor layer 4 from bottom to top. The chip is cut into a hexahedral structure. The surfaces on the sapphire substrate 1 side of the chip and the two sides of the P-type semiconductor layer 4 are the light-emitting surface 01 of the chip, and the remaining four surfaces located on the side of the light-emitti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com