Mixed film applied to energy converter

An energy converter and energy conversion technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, electrical components, etc., can solve the problem of reducing functionality and efficiency and other issues to achieve the effect of reducing loss, improving efficiency and functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

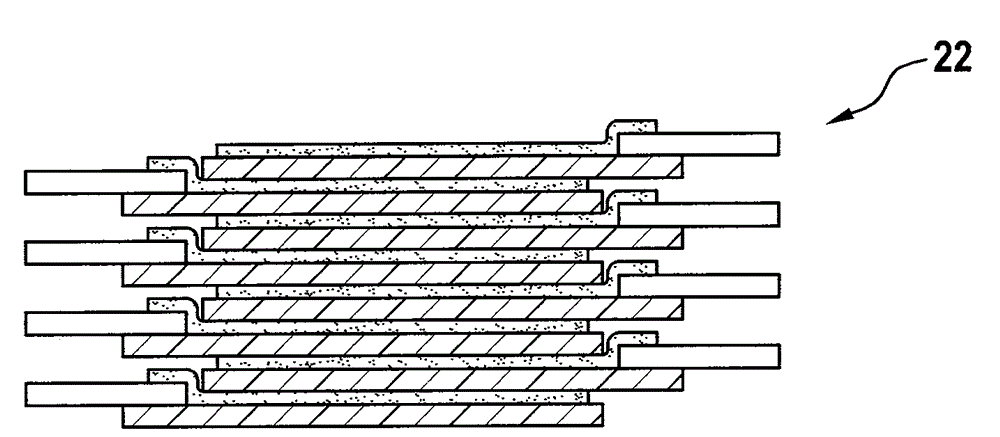

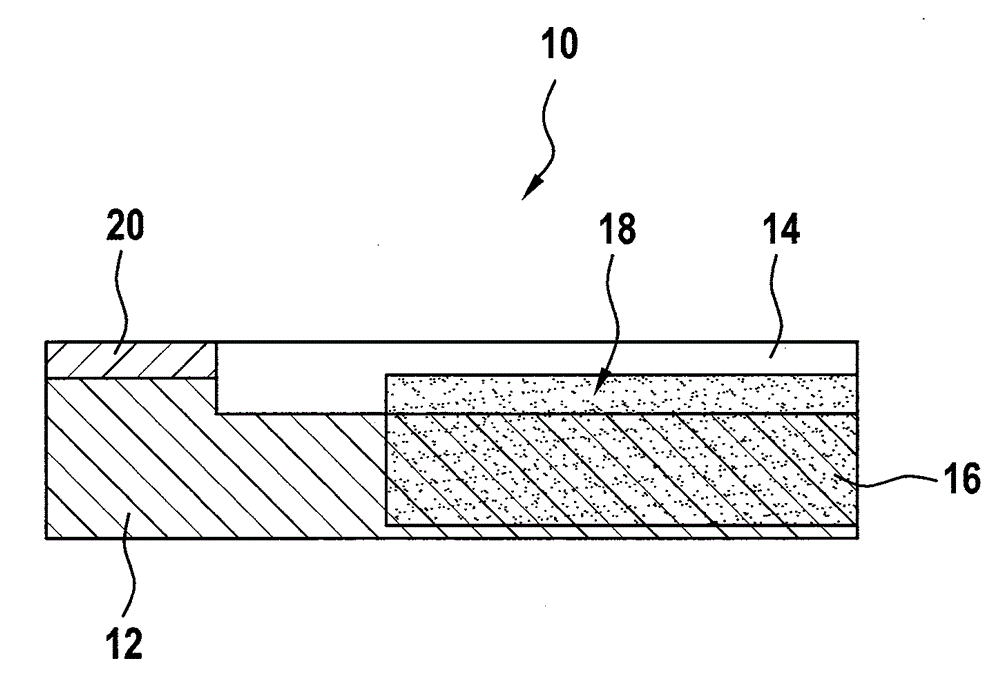

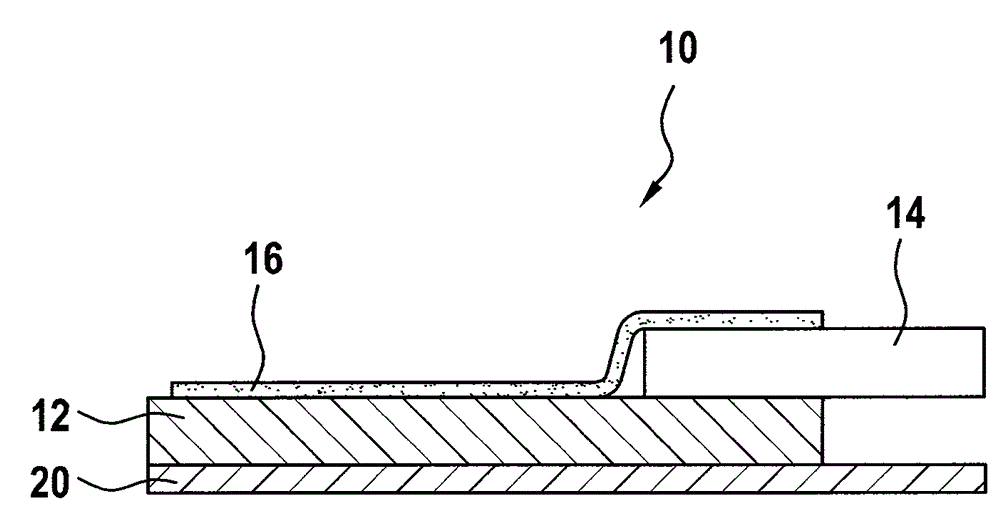

[0051] figure 1 A hybrid membrane 10 for an energy converter 22 is shown, wherein the hybrid membrane 10 is an electroactive polymer membrane (EAP). The hybrid membrane 10 includes a base membrane 12 made, for example, of silicone. The contact film 14 is arranged on the longitudinal sides of the base film 12 . The contact film 14 has a smaller width than the base film 12 . The contact film 14 is, for example, a copper film. Furthermore, an electrode coating 16 is applied to the base film and to the contact film 14 on the hybrid film. The electrode coating 16 is applied by sputtering. exist figure 1 It can be seen from the figure that the base film 12 and the contact film 14 are each present as unrolled rolls. After the electrode coating 16 has been sputtered on, the hybrid film 10 is rolled up again. This makes it possible that the hybrid film 10 can be stored as a roll and that the hybrid film 10 can be cut to the desired shape and length in a further production step. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com