Method for serially connecting square polymer batteries in length direction

A polymer and battery technology, used in secondary batteries, battery assembly machines, secondary battery manufacturing, etc., can solve the problems of reduced efficiency, unfavorable production, and many connecting lines, and achieves improved energy density, easy operation, and economical efficiency. The effect of manpower and electronic wire cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and any similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

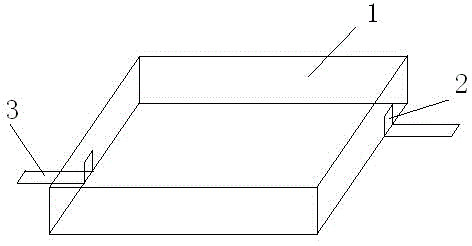

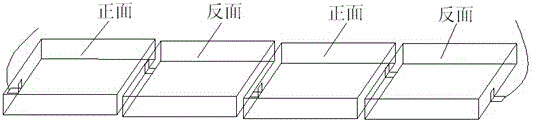

[0018] Such as figure 1 , figure 2 Shown, the present invention works and implements like this, a kind of method for square polymer cell lengthwise series connection, it is characterized in that method step is as follows:

[0019] (1) During the winding process of the machine, place one tab of the battery facing up and the other tab down, so that the tabs of the wound core are on both sides of the core;

[0020] (2) When the machine is winding, a flat core is used for winding. When inserting the sheet, the pole piece is inserted to the bottom, and the edge of the tab is flush with the inner edge of the winding needle. The e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com