An Asymmetric Rotor Linear Rotary Motion Converter

A rotary motion, asymmetric technology, applied in the field of power transmission, can solve the problems of increased vibration of the converter, reduced operating efficiency, increased torque ripple, etc., to avoid noise and vibration, reduce torque ripple, reduce tooth Effect of slot torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

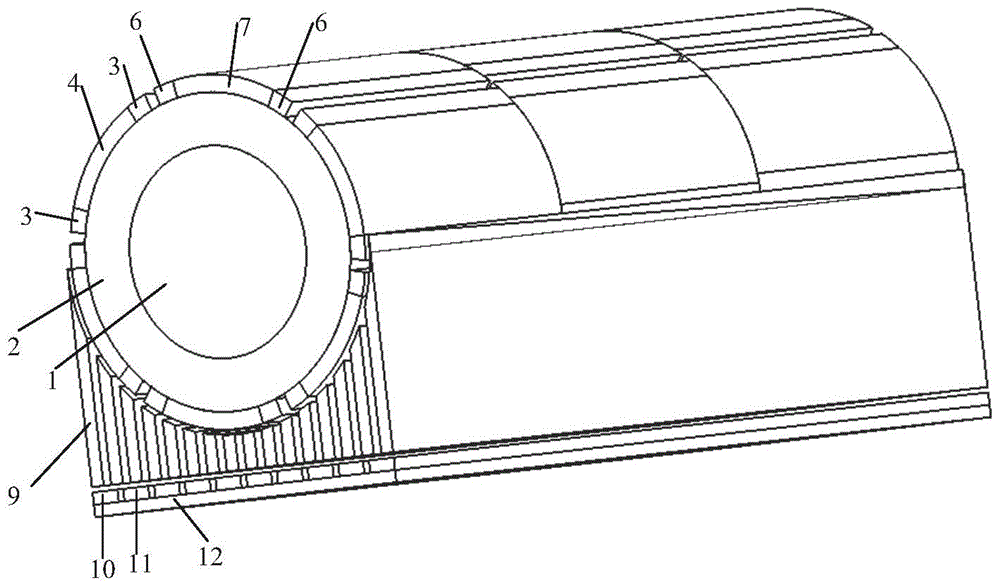

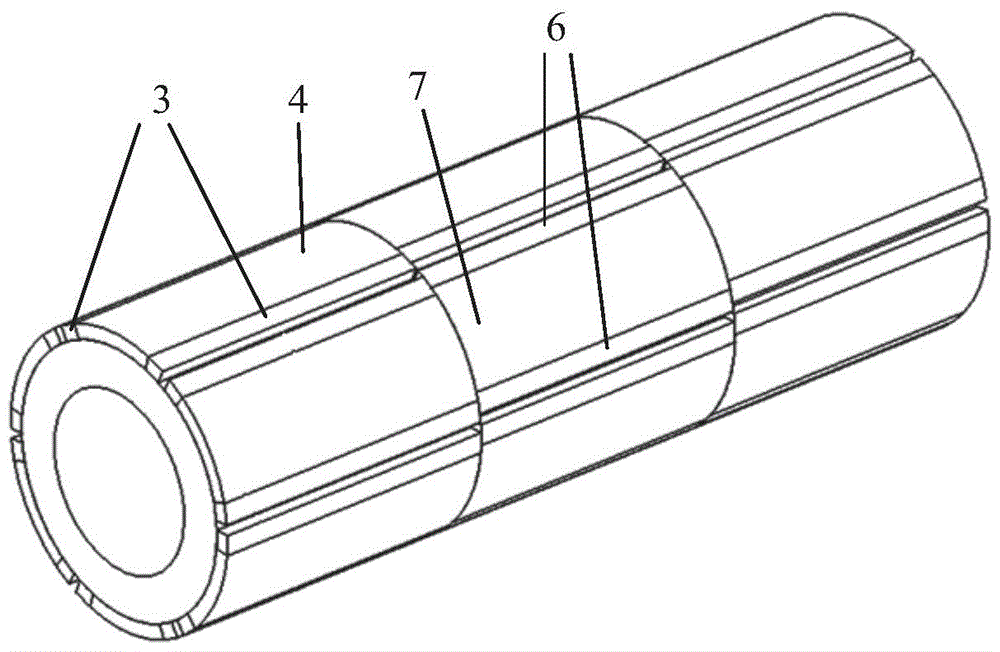

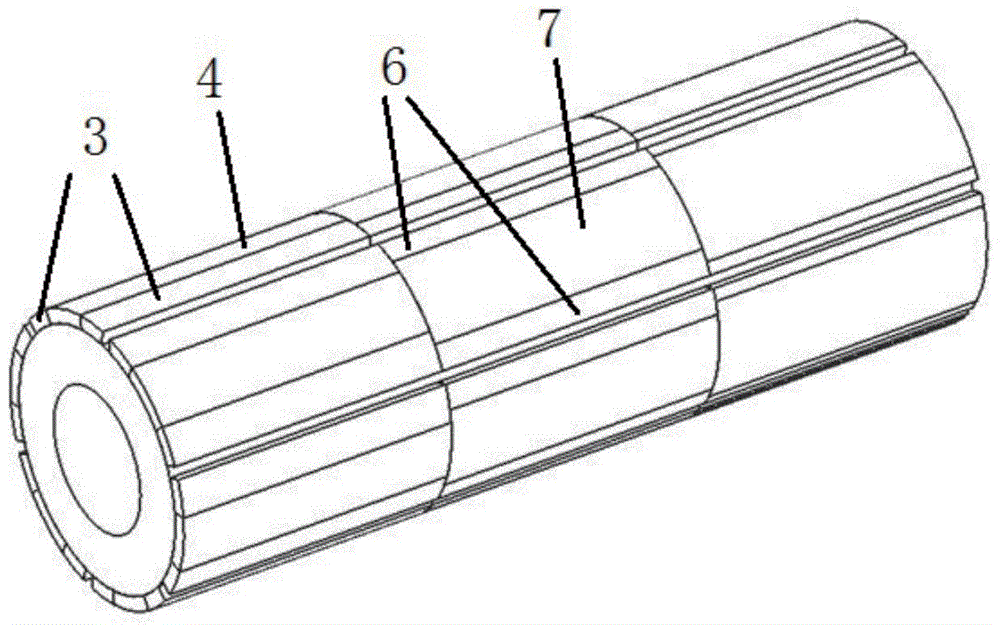

[0031]Embodiment 1: An asymmetric rotor linear rotary motion converter, including a rotary unit, a linear unit, and a magnetic modulation mechanism, the magnetic modulation mechanism is fixedly arranged between the rotary unit and the linear unit. Wherein, the rotating unit includes a rotating shaft 1, a rotor core 2 and a permanent magnet; In this embodiment, the permanent magnets include two pairs of pole permanent magnets, the pole arc coefficient is 0.6, and the permanent magnets include N-pole permanent magnets 4 and S-pole permanent magnets 7 of NdFeB materials with the same central angle, inner and outer diameters and axial lengths. , also includes N-pole permanent magnet 3 and S-pole permanent magnet 6 of ferrite material with equal central angle, inner and outer diameter and axial length. N-pole permanent magnet 4 and S-pole permanent magnet 7 of NdFeB material, and N-pole permanent magnet 3 and S-pole permanent magnet 6 of ferrite material are tile-shaped permanent m...

Embodiment 2

[0037] Embodiment 2: An asymmetric rotor linear rotary motion converter, including a rotary unit, a linear unit, and a magnetic modulation mechanism, and the magnetic modulation mechanism is fixedly arranged between the rotary unit and the linear unit. Wherein, the rotating unit includes a rotating shaft 1 , a rotor core 2 and a permanent magnet. The rotating shaft 1 passes through the shaft hole of the rotor core 2 and is fastened together with the rotor core 2 . The permanent magnet is attached to the surface of the rotor core 2 . In this embodiment, the permanent magnets include two pairs of pole permanent magnets, and the pole arc coefficient is 0.6. The permanent magnets include N-pole permanent magnets 4 and S-pole permanent magnets 7 of NdFeB materials, and N-pole permanent magnets of ferrite materials. 3 and S pole permanent magnet 6. N-pole permanent magnet 4 and S-pole permanent magnet 7 of NdFeB material, and N-pole permanent magnet 3 and S-pole permanent magnet 6 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com