A spiral maxillary sinus lifting device and lifting system

A maxillary sinus and lifting rod technology, which is applied to the field of lifting devices and lifting systems in the maxillary sinus, can solve the problems of implant socket damage, unstable retention, poor bone condition, etc., so as to avoid errors and tediousness, and improve surgical safety. , to avoid the effect of insufficient vision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

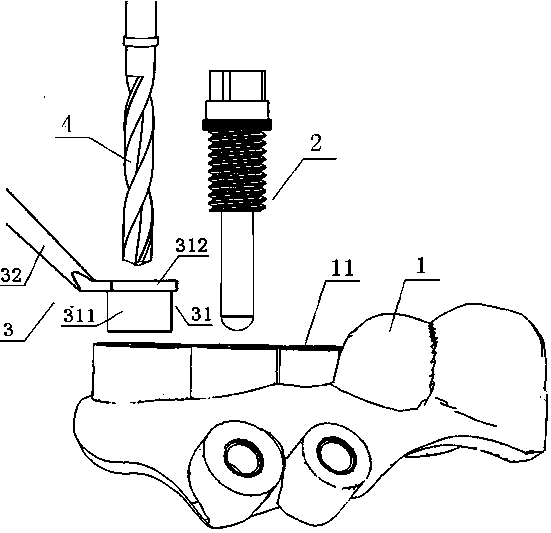

[0025] A lifting device for the maxillary sinus, comprising a positioning guide plate 1, a lifting rod and a ring block gauge 22.

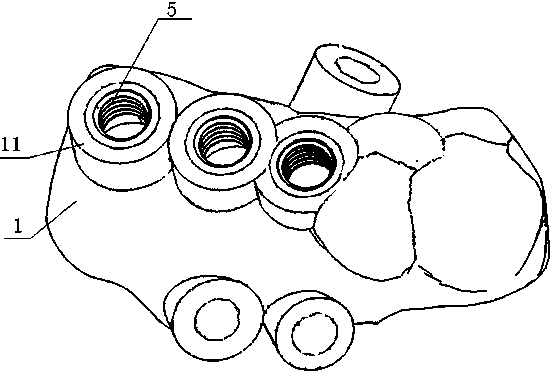

[0026] Such as figure 2 As shown, the positioning guide plate 1 has a guide hole 11 corresponding to the implant socket, and a threaded sleeve 5 is fixed in the guide hole 11, the outer wall of the threaded sleeve 5 is adapted to the guide hole 11, and the inner wall of the threaded sleeve 5 has internal threads .

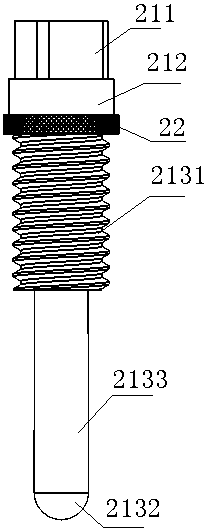

[0027] Such as image 3 and Figure 4 As shown, the lifting rod is composed of a force receiving part 211, a retaining ring 212 and a working part, the force receiving part 211 and the working part are separated by the retaining ring 212, and the working part includes a threaded section 2131, a head 2132 and the threaded section 2131 and the head The connecting section 2133 between the parts 2132 and the threaded section 2131 are engaged with the internal thread of the threaded sleeve 5 .

[0028] Such as Figure 5 As shown, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com