Movable dedusting device in textile workshop

A dust removal device and mobile technology, applied in textiles and papermaking, can solve the problems of high energy consumption, clean lint, dust, and untimely dust removal, and achieve the effects of low energy consumption, good dust removal effect, and timely dust removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

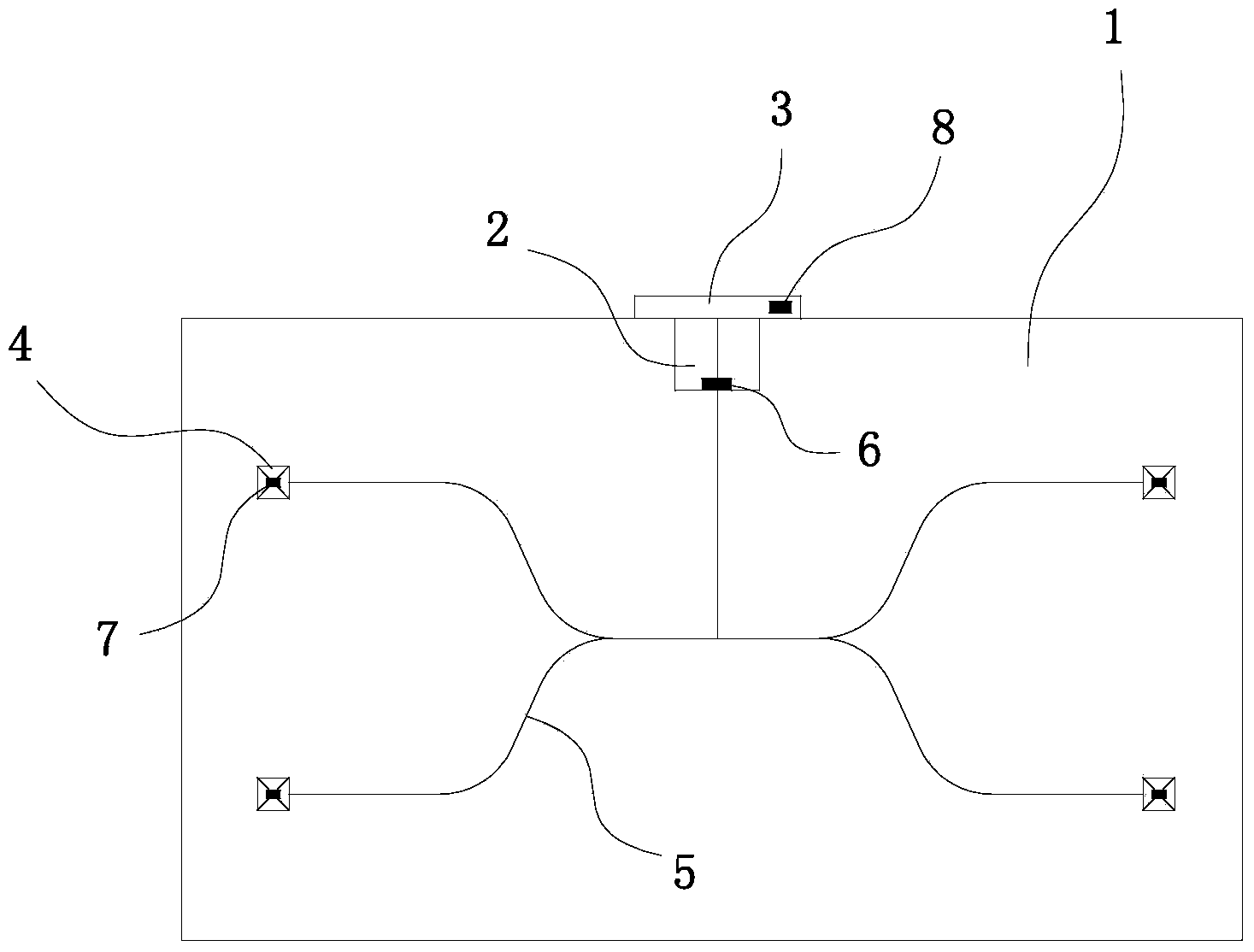

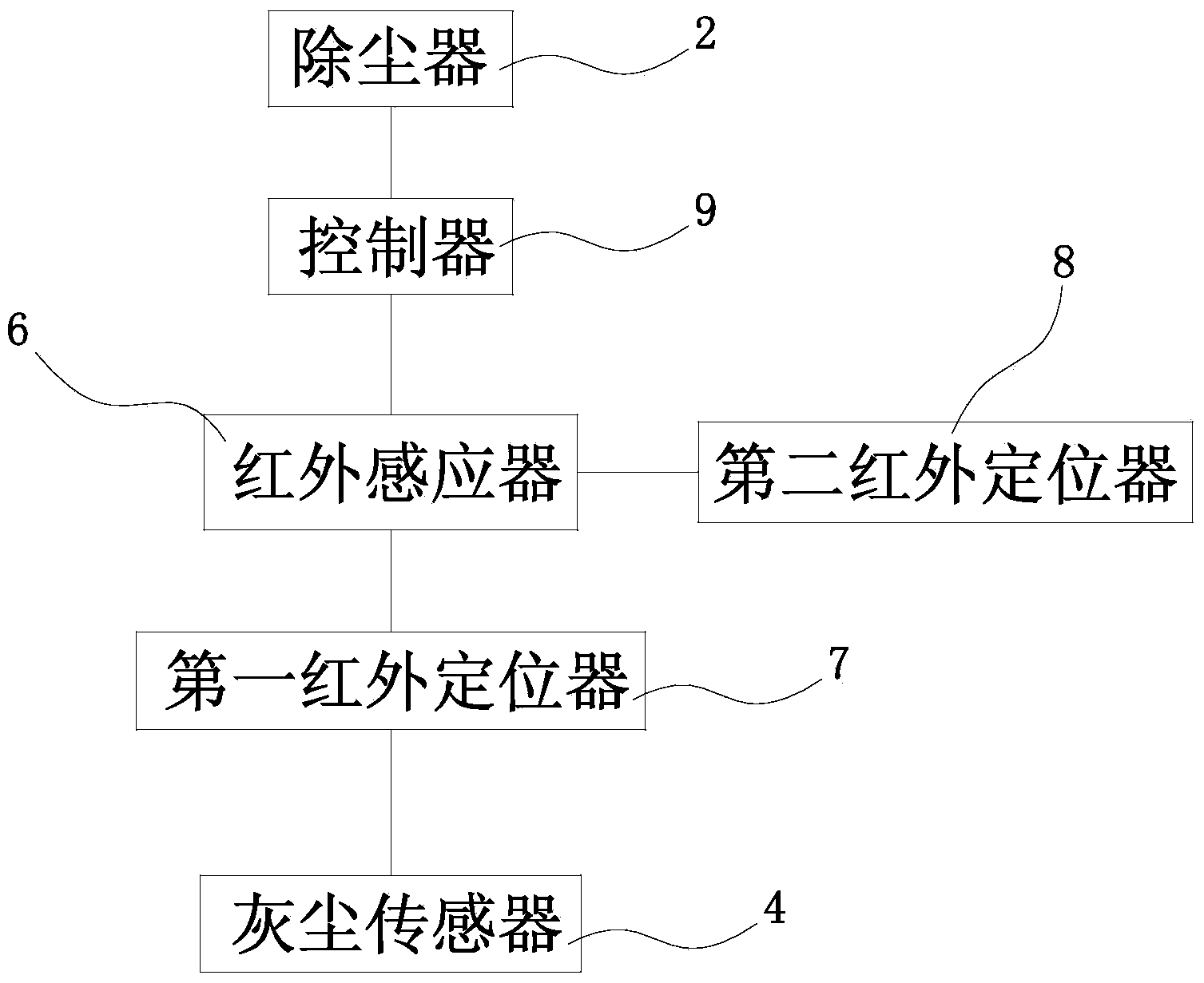

[0017] Such as figure 1 and figure 2 As shown, the mobile dedusting device of the textile workshop of this embodiment includes a plurality of guide rails 5 installed on the top surface of the textile workshop 1, and the branch ends of the guide rails 5 are respectively equipped with dust sensors 4 and first infrared positioners 7;

[0018] The device also includes a dust collector 2 that can move on the guide rail 5 and a solar panel 3 installed on the outer side of the textile workshop 1. The dust collector 2 has an infrared sensor 6, and the solar panel 3 has a second infrared positioning sensor. device 8;

[0019] Have the controller 9 that controls its mobile dedusting on guide rail 5 in the dust remover 2.

[0020] Working process of the present invention is as follows:

[0021] The dust sensor 4 at the branch end of the guide ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com