Multi-stage h-type soil retaining pile and its construction method

A construction method and technology for retaining piles, which are applied in excavation, infrastructure engineering, construction, etc., can solve the problems of easy collapse of foundation pit supporting structures, and achieve the effects of realizing multiple utilization, reducing construction difficulty and shortening construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

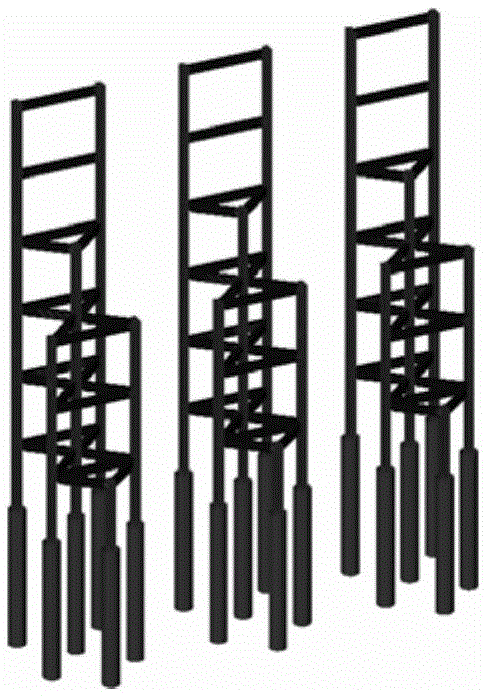

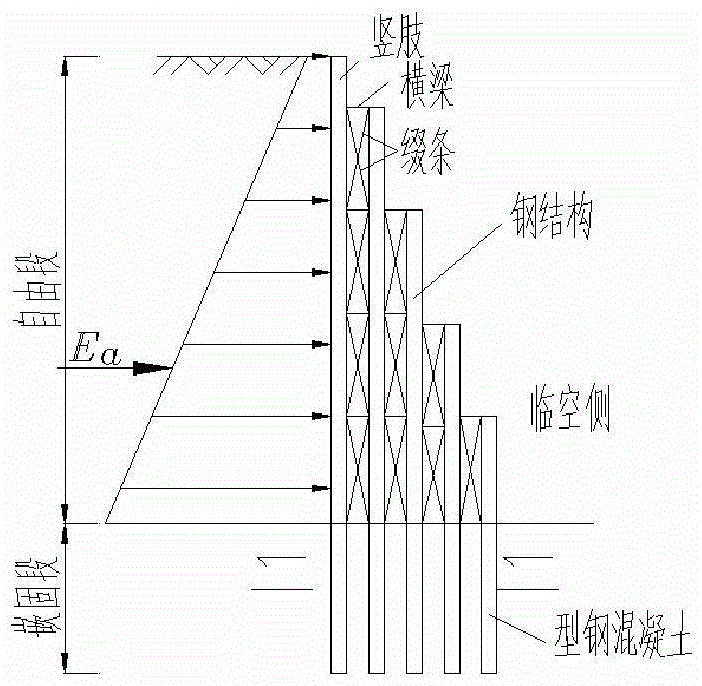

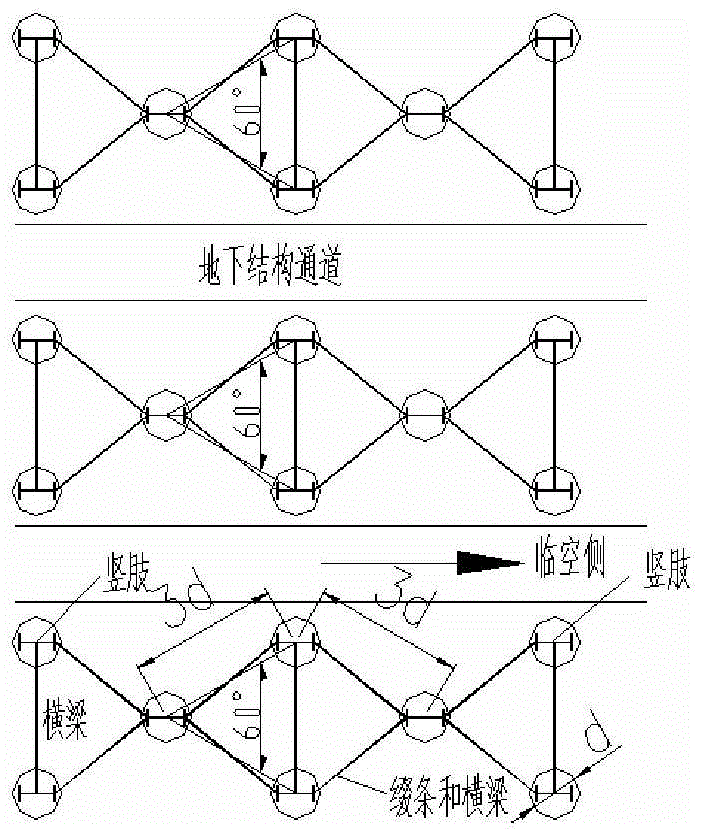

[0038] A multi-stage H-shaped soil retaining pile includes several circles of vertical limbs arranged in a foundation pit, and each circle of vertical limbs is composed of several vertical limbs. see Figure 6 , the figure is a top view of the foundation pit, which is surrounded by several vertical limbs to form three vertical limb circles. The lower end of each vertical limb is inserted into the bottom (base surface) of the foundation pit. The first circle of vertical limbs is in contact with the side wall of the foundation pit, from the first circle of vertical limbs to the Nth circle of vertical limbs ( Figure 6 Among them, N="three", the Nth circle of vertical limbs is the third circle of vertical limbs), gradually approaching the center of the foundation pit. Seen from the direction of the elevation, from the first circle of vertical limbs to the Nth circle of vertical limbs, the height exposed above the bottom of the foundation pit gradually decreases. This makes the...

Embodiment 2

[0042] The main structure of this embodiment is the same as that of Embodiment 1. It includes several vertical limbs with lengths S1, S2...Sn, wherein n is a natural number greater than or equal to 3, and S1>S2>...>Sn. A reinforcement cage is woven on the outer surface of the anchoring section of the vertical limb. Vertical limbs with lengths S1 , S2 . . . Sn are called vertical limbs Z1 , vertical limbs Z2 . . . vertical limbs Zn in sequence. Several vertical limbs Z1 form the first circle of vertical limbs, several vertical limbs Z2 form the second circle of vertical limbs, ..., several vertical limbs Zn form the Nth circle of vertical limbs .

[0043] Specifically, N in this embodiment = "five". That is, it includes several vertical limbs with lengths S1, S2, S3, S4 and S5, wherein S1=21 meters, S2=18 meters, S3=15 meters, S4=12 meters, and S5=9 meters. A reinforcement cage is woven on the outer surface of the anchoring section of the vertical limb. The vertical limbs ...

Embodiment 3

[0050] The main structure of this embodiment is the same as that of Embodiment 1.

[0051] Only, the vertical limbs can be perpendicular to the horizontal plane, or inclined (with a certain angle with the horizontal plane), that is, the angle between each vertical limb and the horizontal plane is α, 0°<α≤90°, preferably Ground: 30°≤α≤90°.

[0052] In addition, in this embodiment, the distance between each vertical limb circle can be close to 0. That is, each circle of vertical limbs is adjacent.

[0053] In one implementation manner, the first circle of vertical limbs is perpendicular to the horizontal plane, and the remaining circles of vertical limbs are all inclined.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com