Pump group state online monitoring system and method

A technology for monitoring systems and machines and pumps, applied in the field of monitoring systems, can solve the problems of small key rotating equipment staying in regular maintenance, affecting the normal production of enterprises, and being unable to realize online real-time status monitoring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

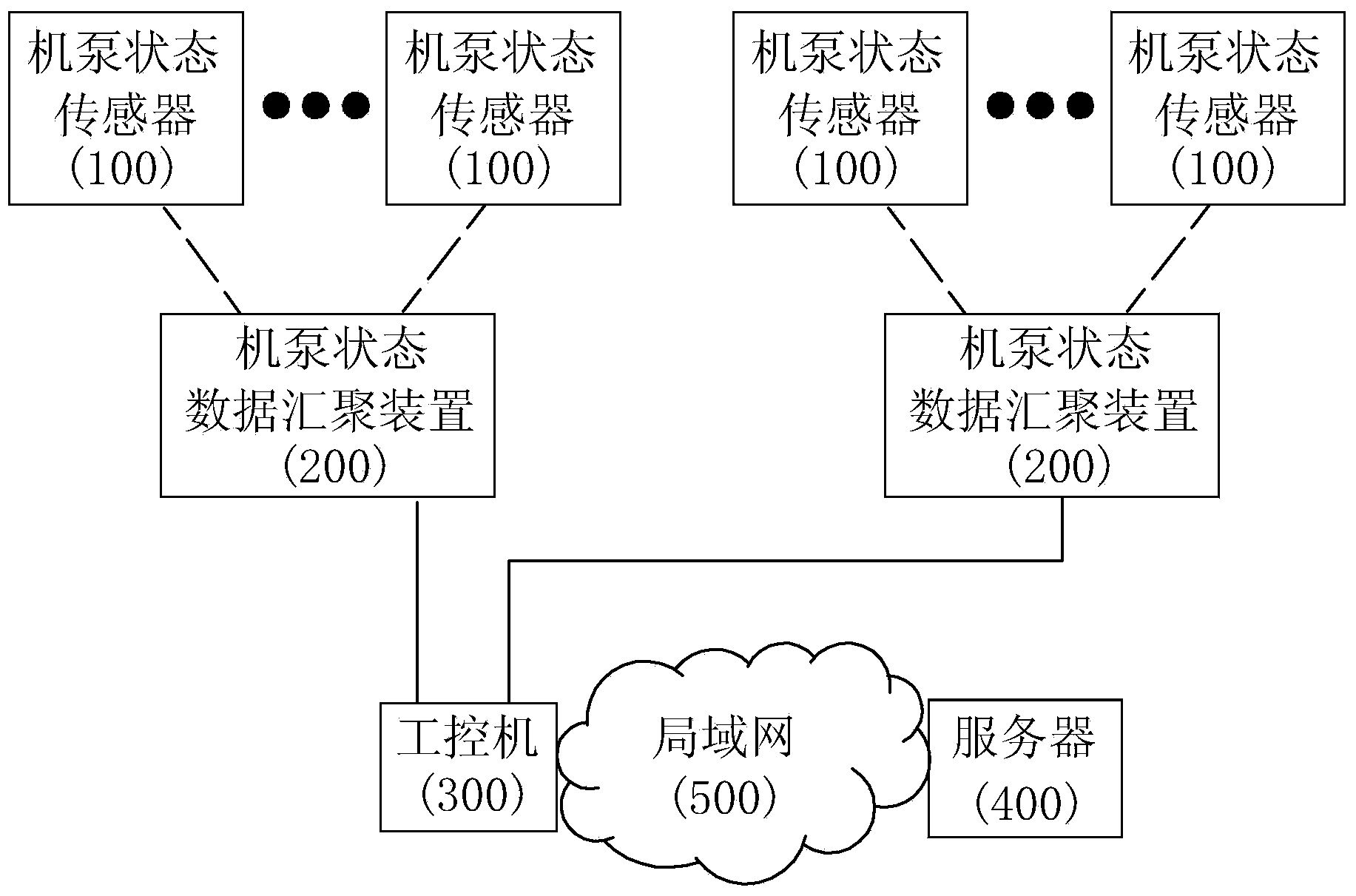

[0028] Embodiment: the machine-pump group status online monitoring system of this embodiment, such as figure 1 As shown, it includes a pump status sensor 100, a pump status data collection device 200, a server 400, and an industrial computer 300 as a monitoring terminal. Multiple pump status sensors can be set according to the number of pumps to be monitored, and the pump status data is aggregated The device can also be provided with multiple devices according to the number of pump state sensors. A pump status sensor 100 is installed on a pump, and a pump status data converging device 200 can be wirelessly connected to multiple pump status sensors 100, figure 1 The dotted line in the middle refers to the wireless connection. Multiple pump state data converging devices 200 are connected to the industrial computer 300 through 485 communication cables, and the industrial computer 300 and the server 400 are both connected to the local area network 500 .

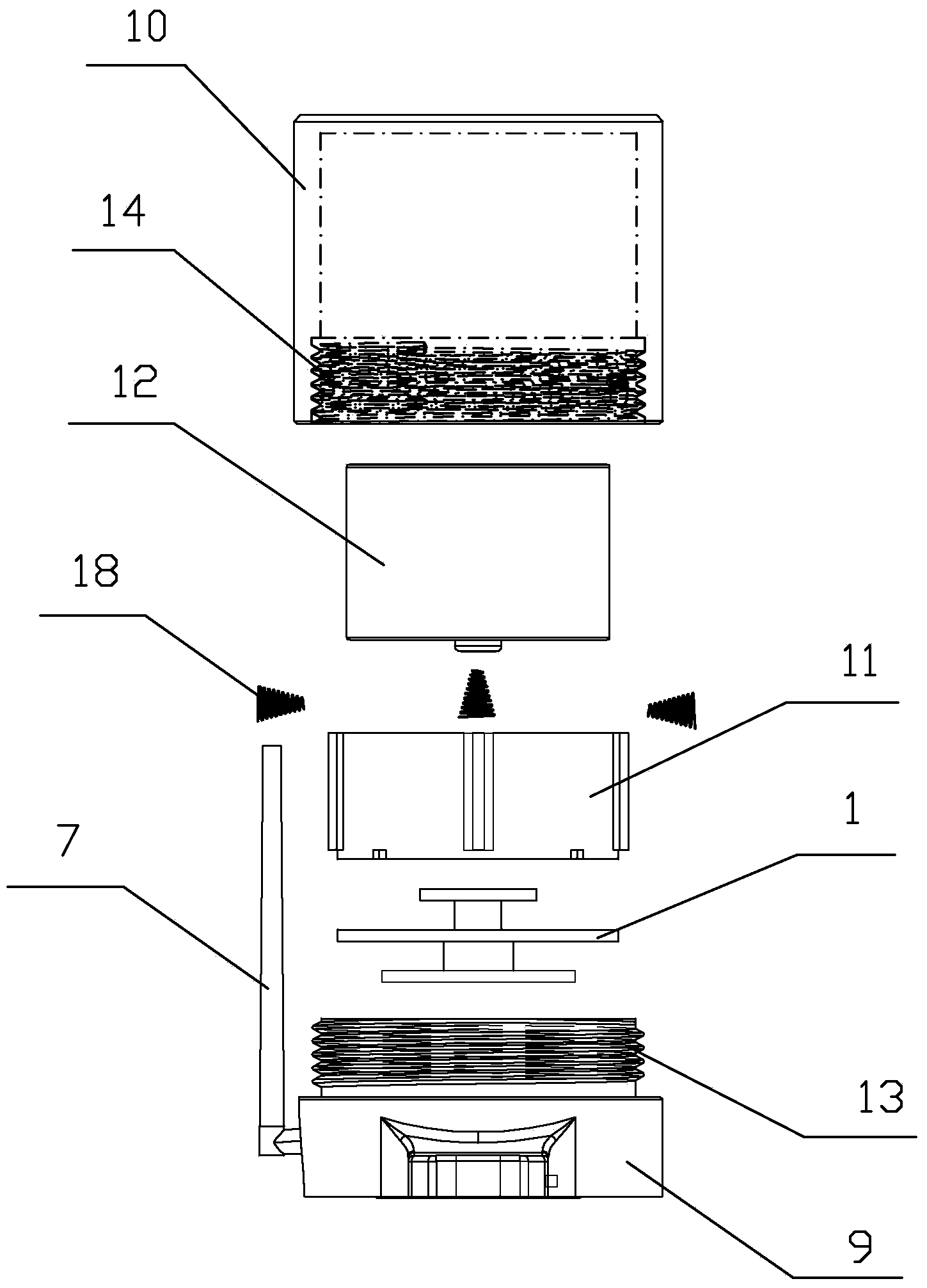

[0029] like figure 2 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com