Piston connecting rod

A piston connecting rod, connecting rod small head technology, applied in the direction of connecting rods, engine components, shafts and bearings, etc., can solve the problems of slow market promotion and application, increased engine comprehensive manufacturing costs, high pin seat temperature, etc., to achieve The structure is simplified, the force is concentrated, and the effect of overcoming the locking of the piston pin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. The following examples are only used to illustrate the present invention, but can not be used to limit the scope of the present invention.

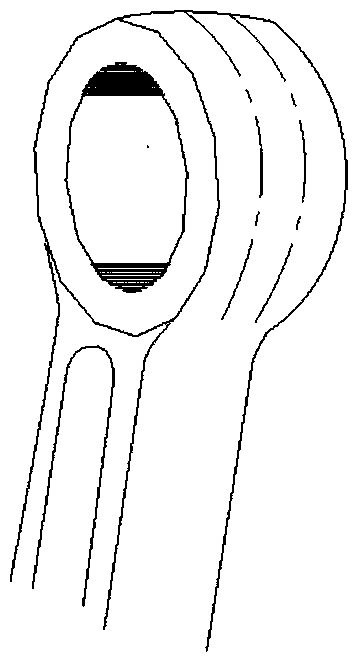

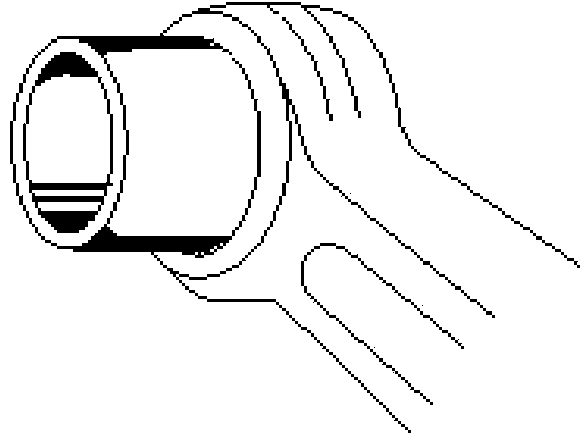

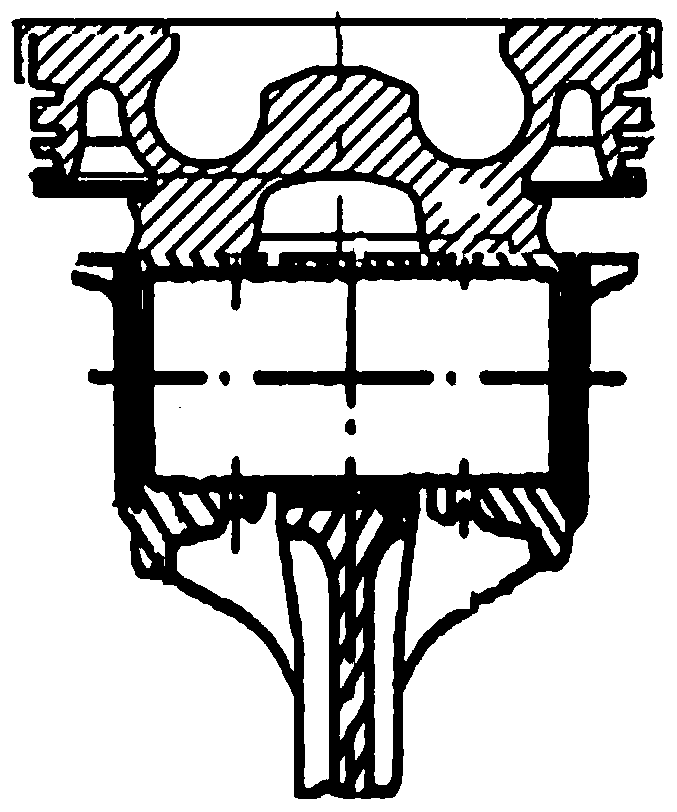

[0028] Figure 4~5 As shown, the present invention provides a piston connecting rod, including a connecting rod small end 1, a connecting rod large end and a shaft, the connecting rod small end 1 is a double-pin seat structure, and the double-pin seat structure is provided with and has a single The pin hole 2 required when the pin seat of the piston head of the pin seat structure is pin-connected; in the double pin seat structure, an oil collecting chamber 5 is arranged in the empty groove in the middle of the two pin seats near one end of the shaft.

[0029] Preferably, the oil collecting chamber is surrounded by the arc-shaped chamber bottom and the side walls insid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com