Material surface color feature on-line automatic detection method

A color feature, automatic detection technology, applied in color/spectral feature measurement, color measurement device, color measurement using color chart, etc. Standardization and other issues, to achieve the effect of the real-time detection method and system of material surface color characteristics is simple and easy to implement, has wide application prospects, and has high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

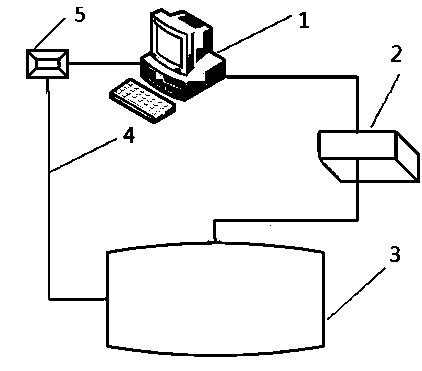

Method used

Image

Examples

Embodiment 1

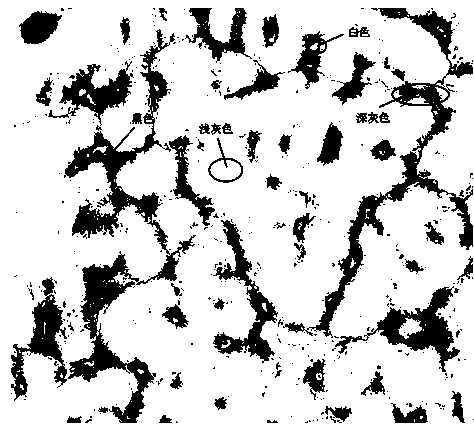

[0046] Such as figure 2 As shown, the A material has four colors: black, dark gray, light gray and white, wherein black and white are impurities, and the less the content, the better. The evaluation criteria for the A material are: (1) Under normal circumstances (without impurities), the proportion of dark gray is 30%, the proportion of light gray is 70%, and the acceptable error is (-1%, 1%) If it meets this standard, it is qualified, otherwise it is unqualified; (2) If it contains impurities, the content of impurities (black and white) is less than 1%, and the proportion of black and white is less than 0.5%, otherwise it is unqualified, only the above two items When both are qualified, the surface quality of the material is qualified, otherwise it is unqualified.

[0047] The online automatic detection method of the surface color characteristics of the material, the specific steps are as follows:

[0048] (1) First select material standard samples according to the real-ti...

Embodiment 2

[0065] Such as Figure 9 As shown, the B material has five colors: black, dark gray, gray, light gray and white. The evaluation standard of the B material is: the proportions of black, dark gray, gray, light gray and white are respectively: 6% , 24%, 6%, 61% and 3%, the acceptable error is (-0.5%, 0.5%), if this standard is met, it is qualified, otherwise it is unqualified.

[0066] The online automatic detection method for the surface color characteristics of the B material, its specific steps are as follows:

[0067] (1) First select material standard samples according to the real-time environment and material types, and take several original images of the surface of the standard samples of materials to be tested by using 6 high-precision cameras that can cover the entire surface of the material standard samples to be tested. After image processing Obtain the standard color classification threshold; the steps for the standard color classification threshold are:

[0068] 1....

Embodiment 3

[0085] The online automatic detection method of the surface color characteristics of the material, the specific steps are as follows:

[0086] (1) First select material standard samples according to the real-time environment and material types, and take 100 original images of the surface of the material standard samples to be tested by using 10 high-precision cameras that can cover the entire surface of the material standard samples to be tested. After image processing Obtain the standard color classification threshold; the steps for the standard color classification threshold are:

[0087] 1.1 Read the surface original images of 100 standard samples of the material to be tested into matlab sequentially using the matlab function imread;

[0088] 1.2 Then use the matlab function rgb2gray to convert each original surface image in step 1.1 from a color image to a grayscale image;

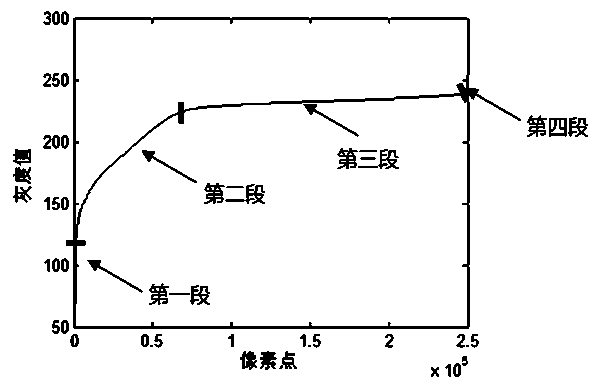

[0089] 1.3 Use the matlab function sort to arrange the pixels of each grayscale image obtained in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| greyscale | aaaaa | aaaaa |

| greyscale | aaaaa | aaaaa |

| greyscale | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com