Liquid crystal panel, display device, and manufacturing method of liquid crystal panel

A technology of liquid crystal panels and manufacturing methods, applied in nonlinear optics, instruments, optics, etc., can solve the problems of difficult manufacturing, complicated manufacturing process, and high technological difficulty, and achieve difficult manufacturing, simplified manufacturing process, and simple manufacturing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

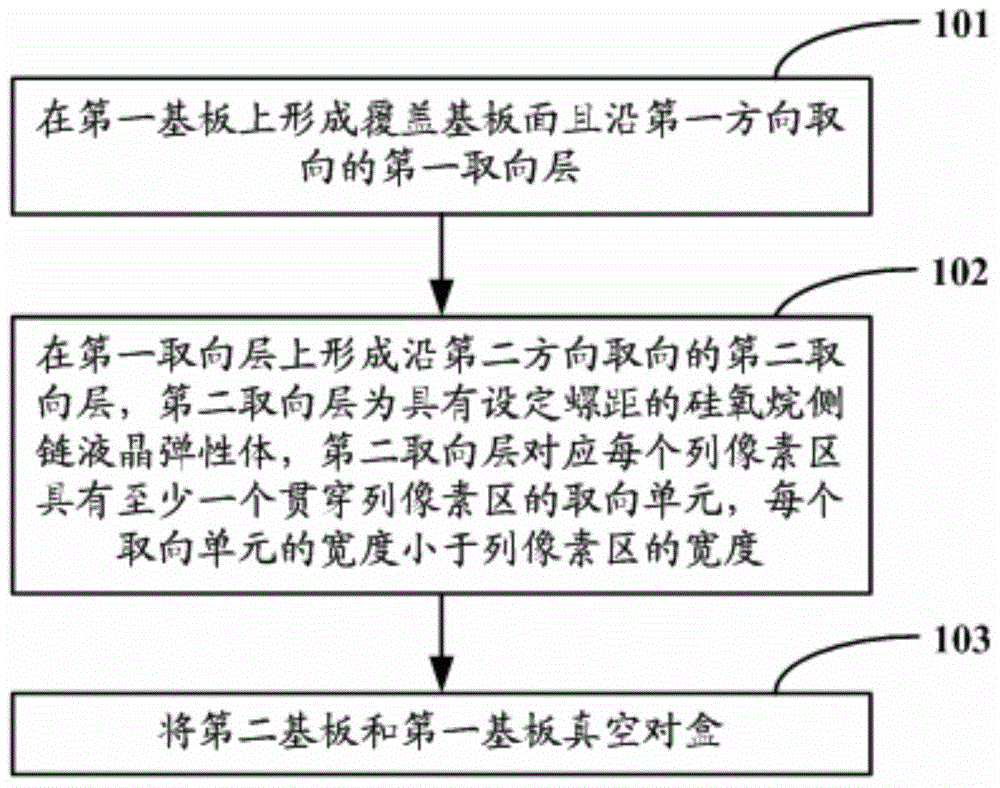

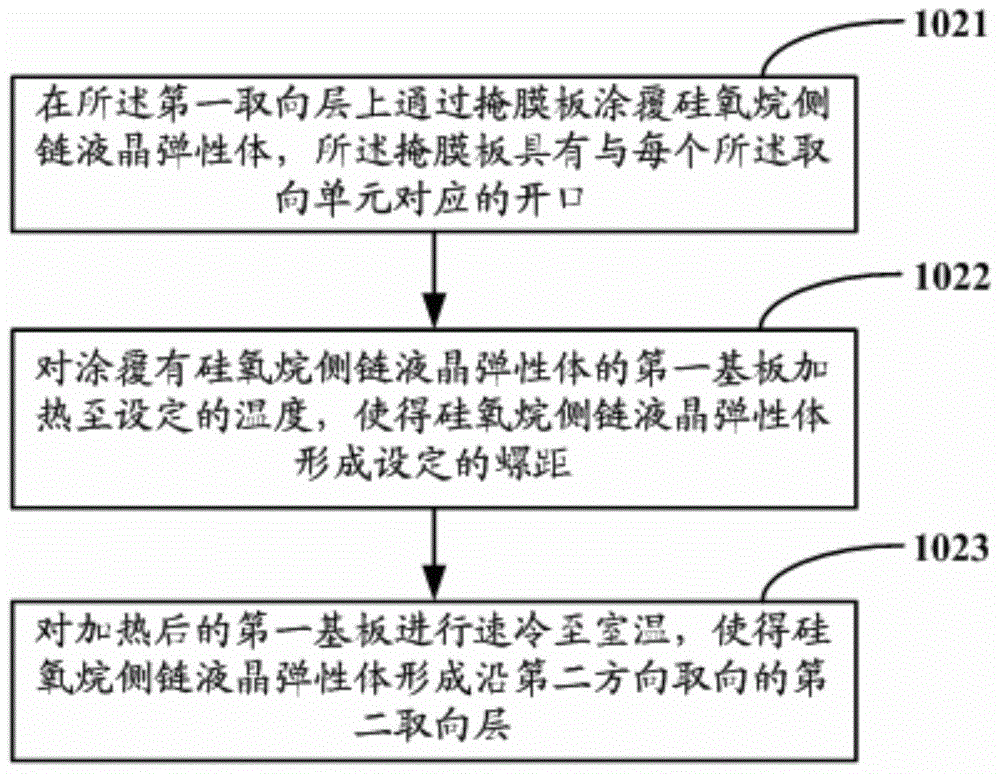

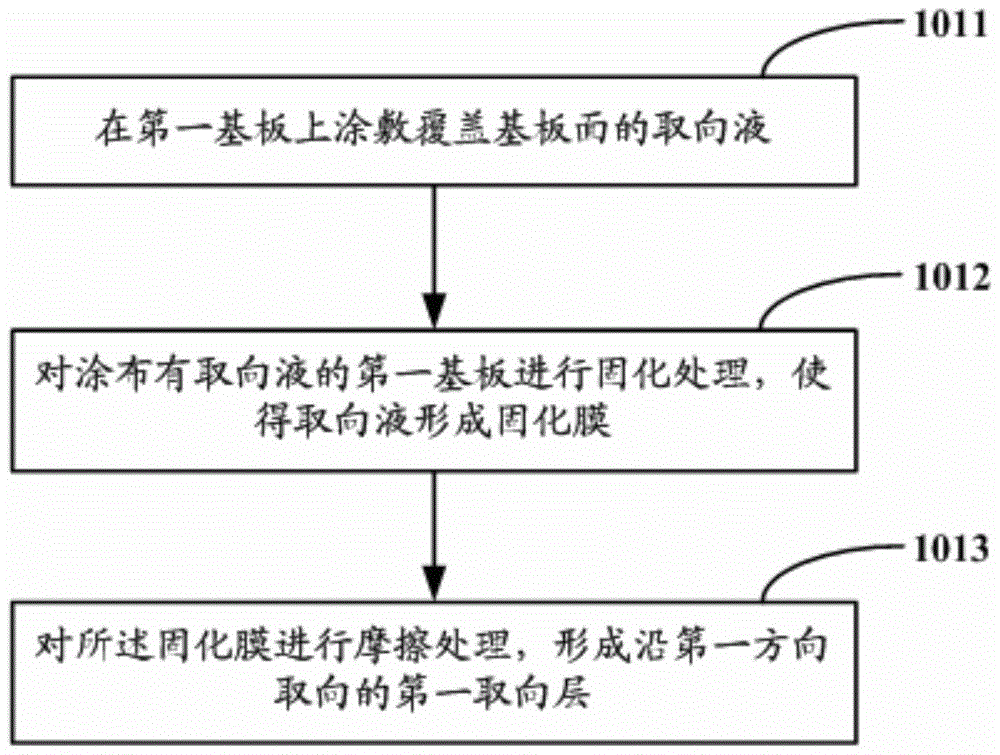

Method used

Image

Examples

Embodiment 1

[0129] Siloxane side chain liquid crystal monomer Y 1 use Figure 5 The siloxane side chain liquid crystal elastomer shown, wherein m=4, n=3, k=3, the crosslinking agent shown in formula II (n=3 in formula II) and the liquid crystallinity shown in formula I The monomers (k=3 in formula I) are grafted in a molar ratio of 1:6. Siloxane side chain liquid crystal monomer Y 1 Helical Twisting Power (HTP for short, the unit is μm -1 ) with temperature (Temperature, unit is ℃) change curve as shown in Figure 15 As shown, its pitch at 70°C is 240nm. Using this siloxane side chain liquid crystal elastomer Y 1 As the second alignment layer, it can be combined with the first alignment layer to form an initial arrangement of multiple liquid crystal molecules in one pixel to realize multi-domain liquid crystal display, including siloxane side chain liquid crystal elastomer Y 1 The production steps of the LCD panel are as follows:

[0130] Form a first alignment layer aligned along ...

Embodiment 2

[0137] Siloxane side chain liquid crystal monomer Y 1 use Figure 5 The siloxane side chain liquid crystal elastomer shown, wherein m=4, n=3, k=3, the crosslinking agent shown in formula II (n=3 in formula II) and the liquid crystallinity shown in formula I The monomers (k=3 in formula I) are grafted in a molar ratio of 1:6. Siloxane side chain liquid crystal monomer Y 1 The curve of the twisting force of the spiral with temperature is as follows Figure 15 As shown, the pitch is 680nm at 100°C (due to the large ordinate Figure 15 not shown). Using this siloxane side chain liquid crystal elastomer Y 1 As the second alignment layer, it can be combined with the first alignment layer to form an initial arrangement of multiple liquid crystal molecules in one pixel to realize multi-domain liquid crystal display, including siloxane side chain liquid crystal elastomer Y 1 The production steps of the LCD panel are as follows:

[0138] Form a first alignment layer aligned along...

Embodiment 3

[0145] Siloxane side chain liquid crystal monomer Y 2 use Figure 5 The siloxane side chain liquid crystal elastomer shown, wherein m=4, n=3, k=3, the crosslinking agent shown in formula II (n=3 in formula II) and the liquid crystallinity shown in formula I The monomers (k=3 in formula I) were grafted in a molar ratio of 3:2. Siloxane side chain liquid crystal monomer Y 2 Helical Twisting Power (HTP for short, the unit is μm -1 ) with temperature (Temperature, unit is ℃) change curve as shown in Figure 16 As shown, its pitch at 100°C is 220nm (due to the smaller ordinate, Figure 16 not shown). Using this siloxane side chain liquid crystal elastomer Y 2 As the second alignment layer, it can be combined with the first alignment layer to form an initial arrangement of multiple liquid crystal molecules in one pixel to realize multi-domain liquid crystal display, including siloxane side chain liquid crystal elastomer Y 2 The production steps of the LCD panel are as follows...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com