System and method for estimating position angle of rotor of permanent magnet synchronous motor based on visualization

A permanent magnet synchronous motor, rotor position angle technology, applied in the direction of calculation, measurement device, electrical digital data processing, etc., can solve the problems of increasing the failure rate, increasing the failure rate, complexity, etc., and achieving the effect of reducing the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]LabVIEW integrates the work of creating the user interface (called a front panel) naturally into the development cycle. LabVIEW programs / subroutines are called virtual instruments (VIs). Each VI has three components: block diagram, front panel, and icons / connectors. The linker is used for other block diagrams to call this VI. Programmers can use the controls on the front panel to input data into the running VI, or use the indicators to output the results of calculations. The front panel can also be used as a program interface: each virtual instrument can use the front panel as a user interface and run as a program; it can also be placed as a node in another VI block diagram and connected through the connector panel. The front panel defines the VI's inputs and outputs. This means that each VI can be easily tested before being embedded as a subroutine in a larger project.

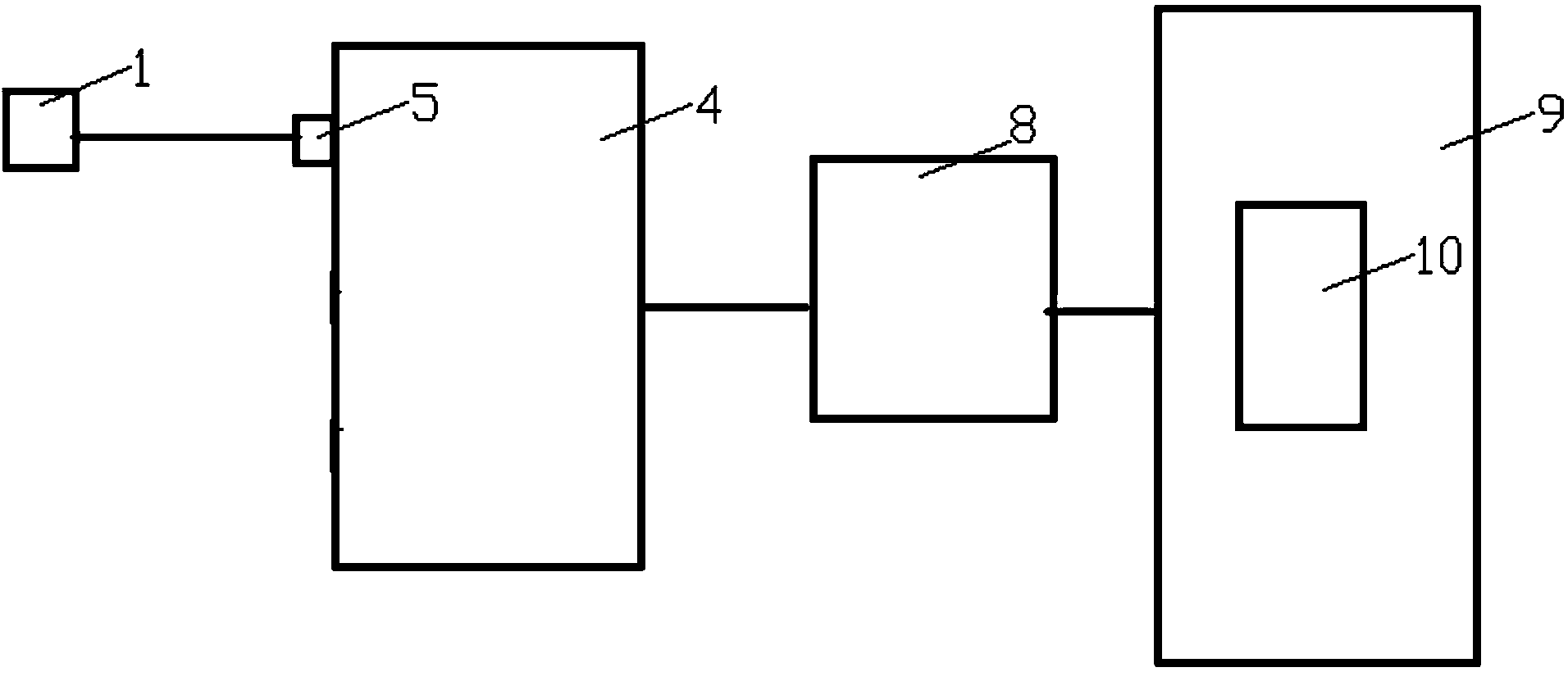

[0024] Such as figure 1 As shown, the visualization-based permanent magnet synchronous motor ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com