Plate-type water cooling electrode assembly plasma surface treatment device with continuous treatment function

A surface treatment device and plate-type water-cooling technology, which is applied in the direction of circuits, discharge tubes, electrical components, etc., to achieve the effects of high efficiency, high degree of functional integration, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

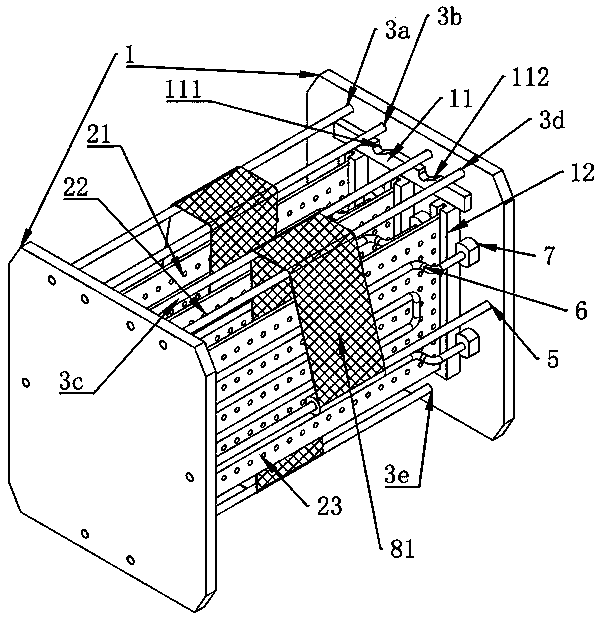

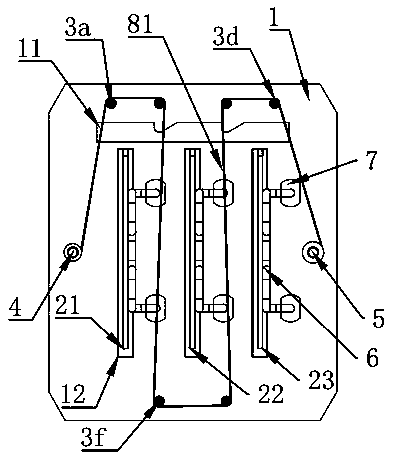

[0021] Embodiment one, such as figure 1 with figure 2 The surface treatment unit shown here is suitable for plasma surface treatment of (flexible) webs. It can be seen from the figure that the processing object of the device is the coil 81 . And the device has two vertical plates 1 and three electrode plates 21 , 22 , 23 arranged in parallel and separated by a certain distance. These electrode plates are vertically arranged between the two vertical plates 1 and are parallel to each other in groups. The vertical plate 1 is fixedly connected with a fixture plate 11 and three sets of insulating plates 12 corresponding to the number of electrode plates. 1 Four guide rollers 3a, 3b, 3c, 3d are arranged on the upper side of the opposite electrode plate longitudinal direction, and two guide rollers 3e, 3f are arranged on the lower side, and discharge rollers 4 are respectively installed on both sides vertically opposite to the electrode plate group and the receiving roller 5, and...

Embodiment 2

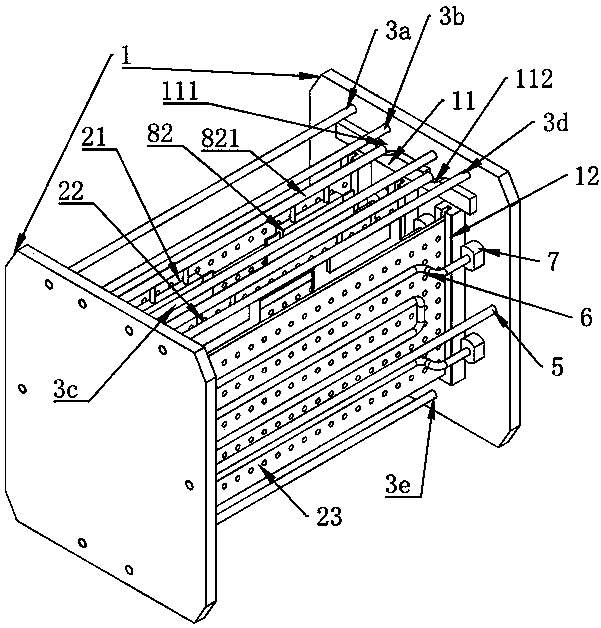

[0024] Embodiment two, such as image 3 with Figure 4 The surface treatment unit shown here is suitable for plasma surface treatment of sheet metal (partially rigid). It can be seen from the diagram that the processing object of the device is a plate 82, and a plate support 821 is integrally installed therein. And the device has two vertical plates 1 and three electrode plates 21 , 22 , 23 arranged in parallel and separated by a certain distance. These electrode plates are vertically arranged between the two vertical plates 1 and are parallel to each other in groups. The vertical plate 1 is fixedly connected with a fixture plate 11 and three sets of insulating plates 12 corresponding to the number of electrode plates. 1 Four guide rollers 3a, 3b, 3c, 3d are arranged on the upper side of the opposite electrode plate longitudinal direction, and two guide rollers 3e, 3f are arranged on the lower side, and discharge rollers 4 are respectively installed on both sides vertically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com